Garbage treatment method and comprehensive utilization

A garbage treatment and garbage technology, applied in the field of garbage treatment and its comprehensive utilization, can solve the problems of difficult recycling, lower thermal efficiency, pollute the environment, etc., and achieve the effect of reducing highly toxic gas dioxins and sulfides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention is described in further detail by the following examples.

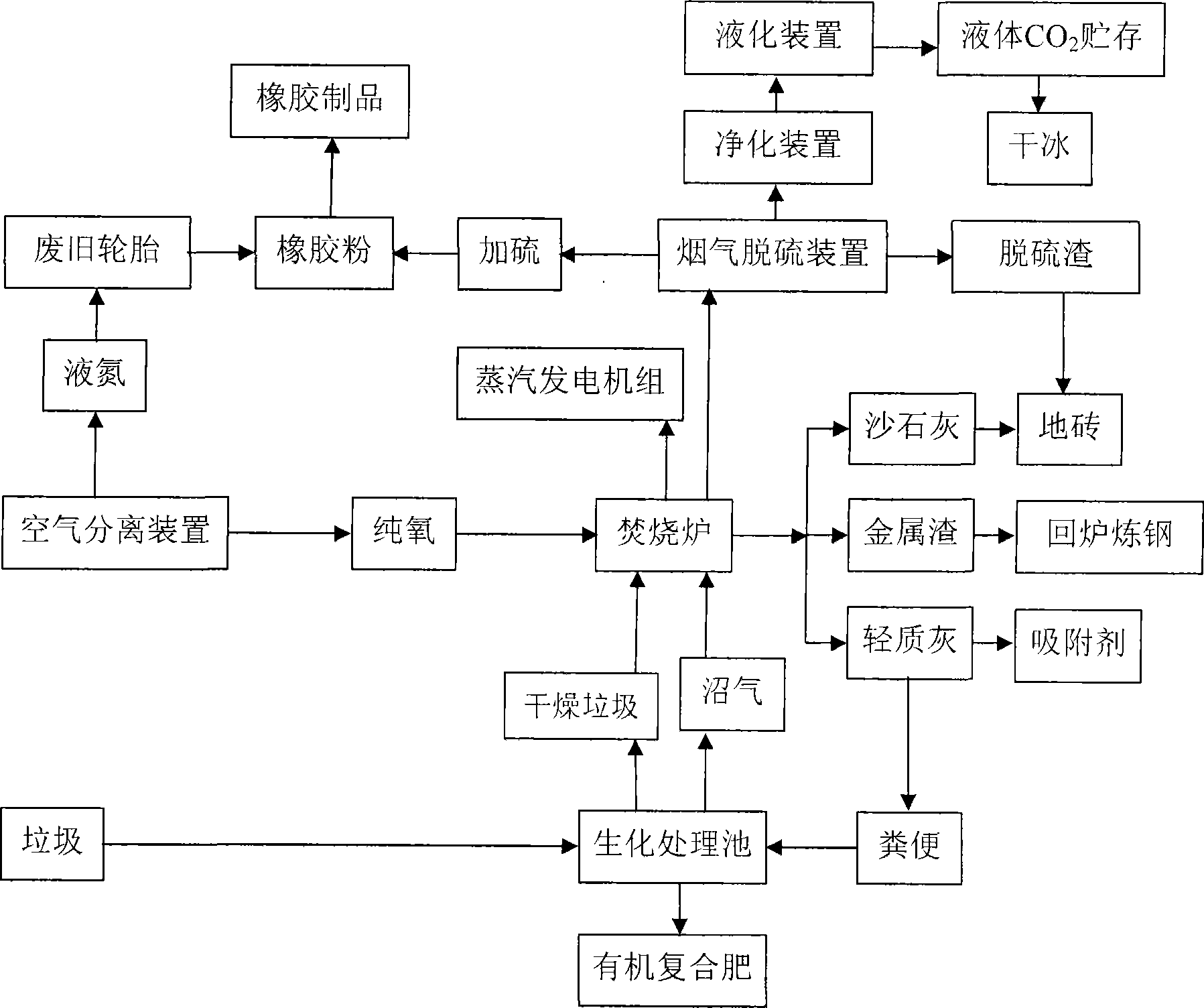

[0013] see figure 1 As shown, the present invention provides a garbage disposal method and the comprehensive utilization of smoke, heat, ash and other substances produced in the garbage disposal process, so as to realize the purpose of zero discharge, pollution-free and waste resource utilization in garbage disposal. The garbage treatment method of the present invention is as follows: the garbage is sent into the biochemical treatment tank, and after 3-7 days of biochemical treatment, biogas is generated, and the rest of the garbage is sent to the incinerator after being dried by the waste heat of the flue gas, and the biogas in the biochemical treatment tank is passed into the incinerator The dry garbage is ignited in the furnace, and the pure oxygen produced by the air separation device is passed into the incinerator to support the combustion of garbage. High concentrations of CO are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com