Carbon Dioxide Pellet Cooling Safety Helmet and a Flexible Carbon Dioxide Pellet Containment and Vapor Diffusion Fabric Segment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

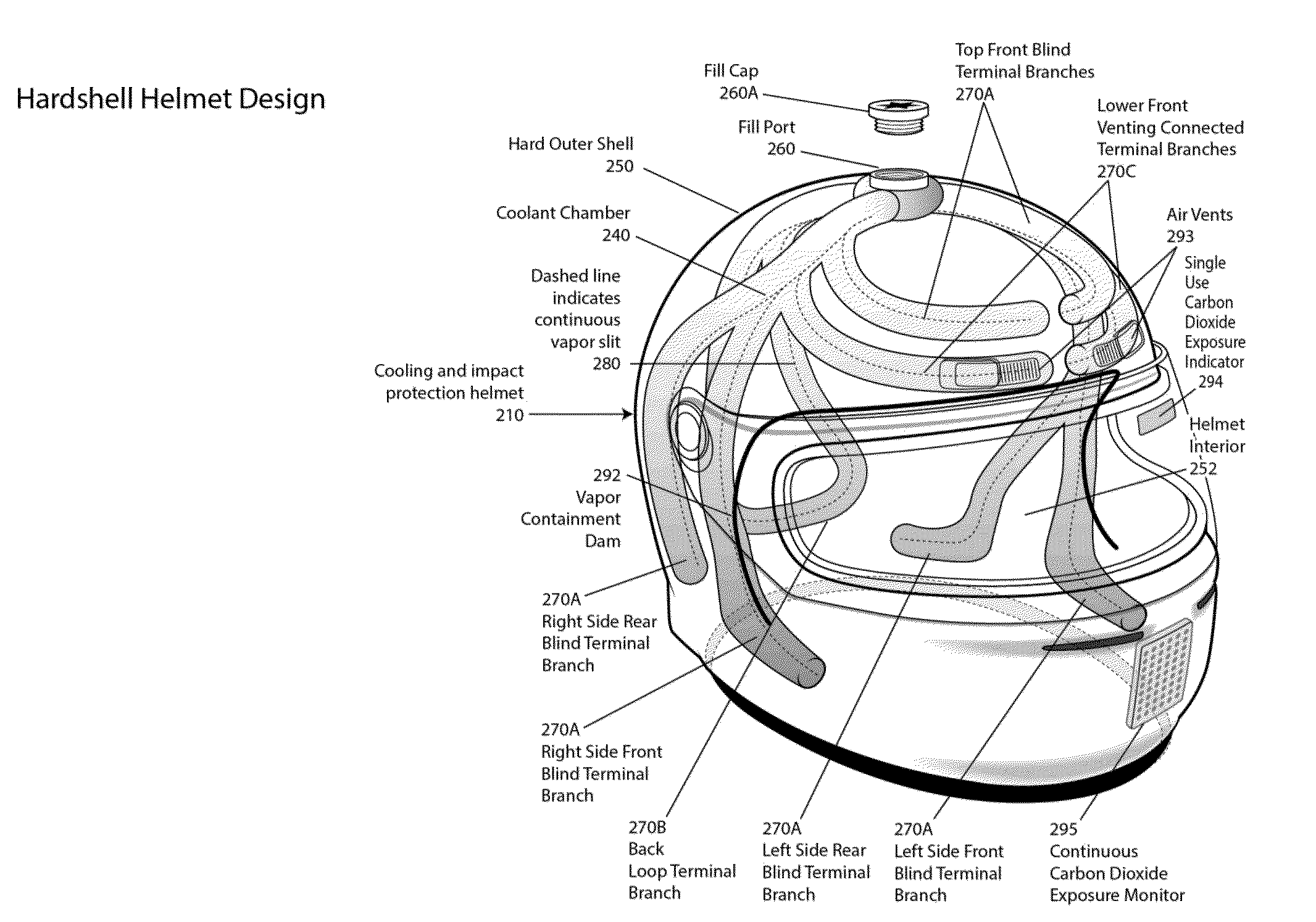

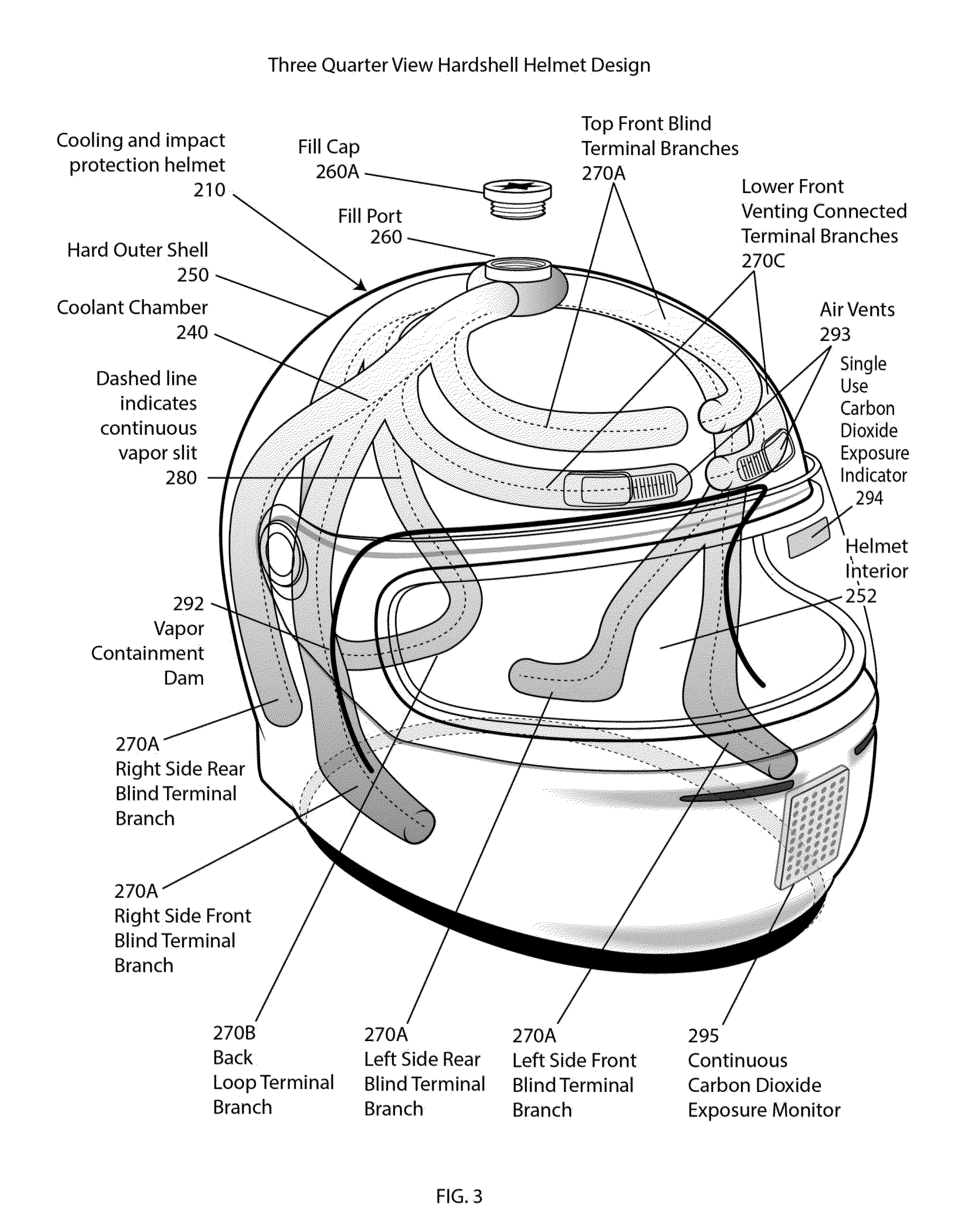

[0055]The manner and process of using the Cooling and Impact Protection Safety Helmet 210 embodiment is achieved by means of the placement of suitably sized Carbon-Dioxide Pellets 100, most commonly derived from the extrusion process, into the Coolant Chamber 240. The exact process of use involves the removal of an access cover, called the Fill Cap 260A, from the Fill Port 260 at the origin point of the Coolant Chamber 240. This is followed by pouring the Carbon-Dioxide Pellets 100 through the Fill Port 260 into the Coolant Chamber 240. Vibration of the Cooling and Impact Protection Safety Helmet 210 by mechanically or hand applied means is applied until the Coolant Chamber 240 is full.

[0056]When the Coolant Chamber 240 is full, the Fill Cap 260A is reinstalled. The vibration serves to maximize the volume of Carbon-Dioxide Pellets 100 placed during the filling process by minimizing the formation of blockages and voids that may result from clumping together of the Carbon-Dioxide Pell...

second embodiment

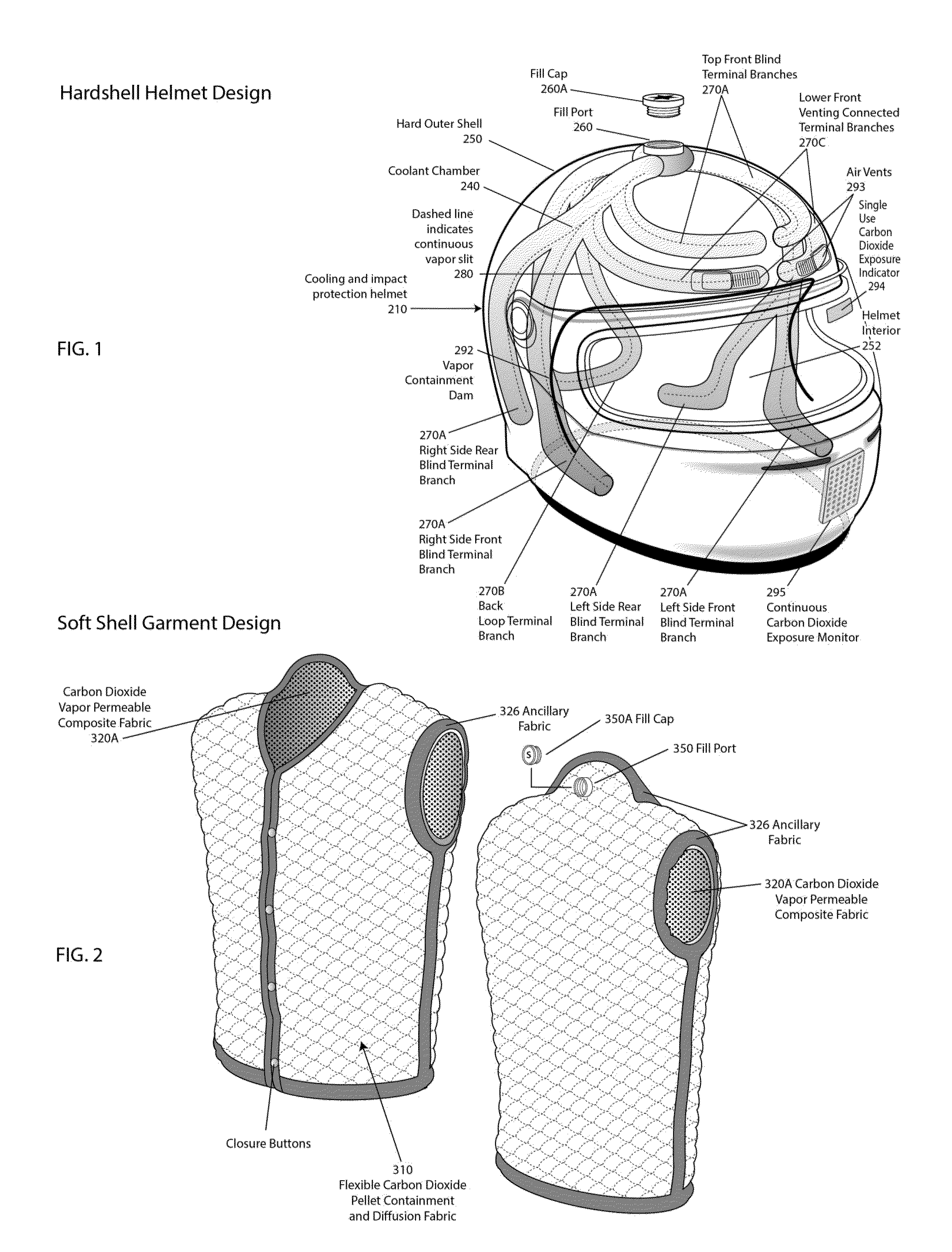

[0065]The use of the Soft-Shell Design 300 embodiment involves orienting the garment with the Fill Port 350 at the highest vertical position. The Fill Port 350 is accessed by removal of the Fill Cap 350A. The Coolant Chamber 330 is then filled with suitably sized Carbon-Dioxide Pellets 101 by means of gravity and vibration assistance. The Fill Cap 350A is then placed in the Fill Port 350 and the garment is donned. Carbon-Dioxide Vapor 101 produced by the sublimation of Carbon-Dioxide Pellets 100 within the Coolant Chamber 330 escapes through the Carbon-Dioxide Vapor-Permeable Insulation Material 322B and overlying Carrier Fabric 324 toward the garment interior, whereby it absorbs heat. Subsequently, the heat-laden Carbon-Dioxide Vapor 101 diffuses out of the garment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com