Comprehensive recovery and utilization method for exhaust gas

A comprehensive method and tail gas recovery technology, applied in separation methods, chemical instruments and methods, applications, etc., can solve environmental pollution and other problems, achieve the effects of reducing air pollution, increasing agricultural and forestry output, and promoting environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

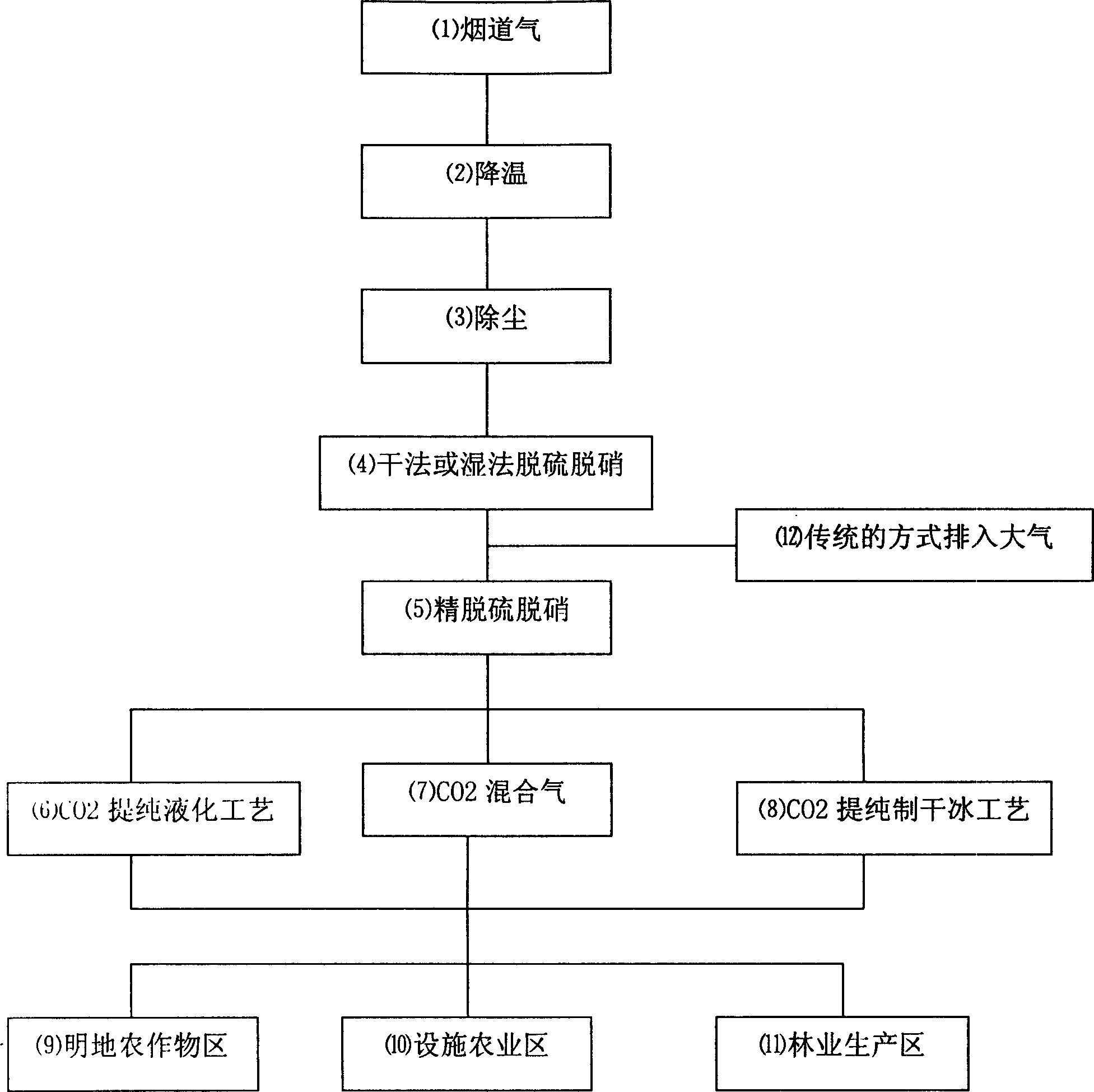

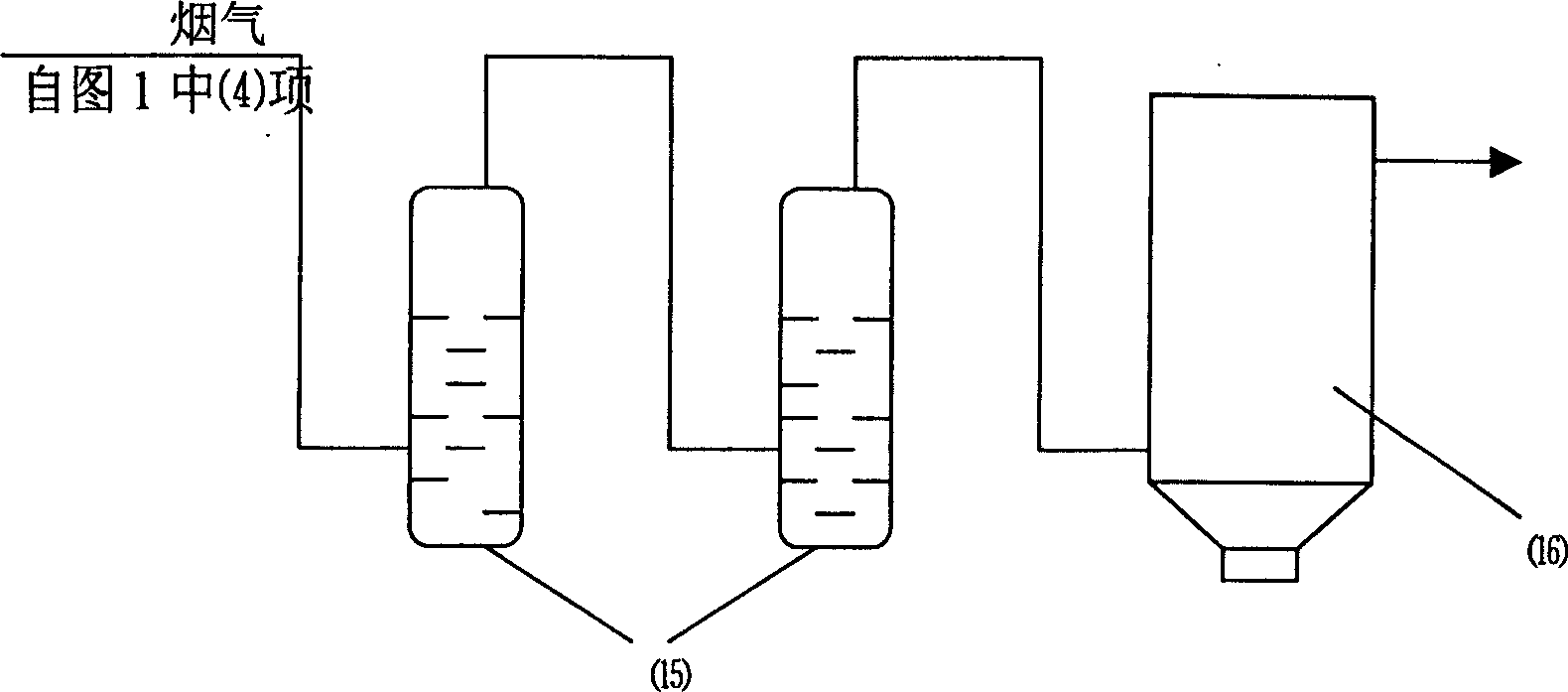

[0013] exist figure 1 Among them, (1), (2), (3), (4), and (12) are the existing traditional exhaust gas emission methods of coal-fired boilers;

[0014] (1), (2), (3), (4), (5), {(6), (7), (8)}, {(9), (10), (11)} are the present invention A comprehensive method for the recovery and utilization of coal-fired boiler tail gas is proposed.

[0015] exist figure 1 In, CO 2 Purification and liquefaction process (6) is to produce liquid carbon dioxide (purity above 99.5%), which is injected into pipelines for transportation or injected into containers and transported by vehicles; 2 The gas pipeline (7) is a mixed gas (low pressure CO 2 , oxygen, nitrogen) are transported by pipeline; CO 2 Purification dry ice process (8) is to produce CO 2 Solid, with insulation measures, transported by vehicle.

[0016] exist figure 1 In the illustrated embodiment, the facility agriculture area (10) is a year-round time period, and CO is applied during the day. 2 ; Under the natural conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com