Storage container

a storage container and temperature control technology, applied in the direction of containers, domestic cooling devices, caps, etc., can solve the problems of increasing the running cost, not only the amount of solid carbon dioxide, and taking a lot of trouble for refilling solid carbon dioxide, so as to reduce the possibility of forming gaps and enhance the insulating performance of storage containers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

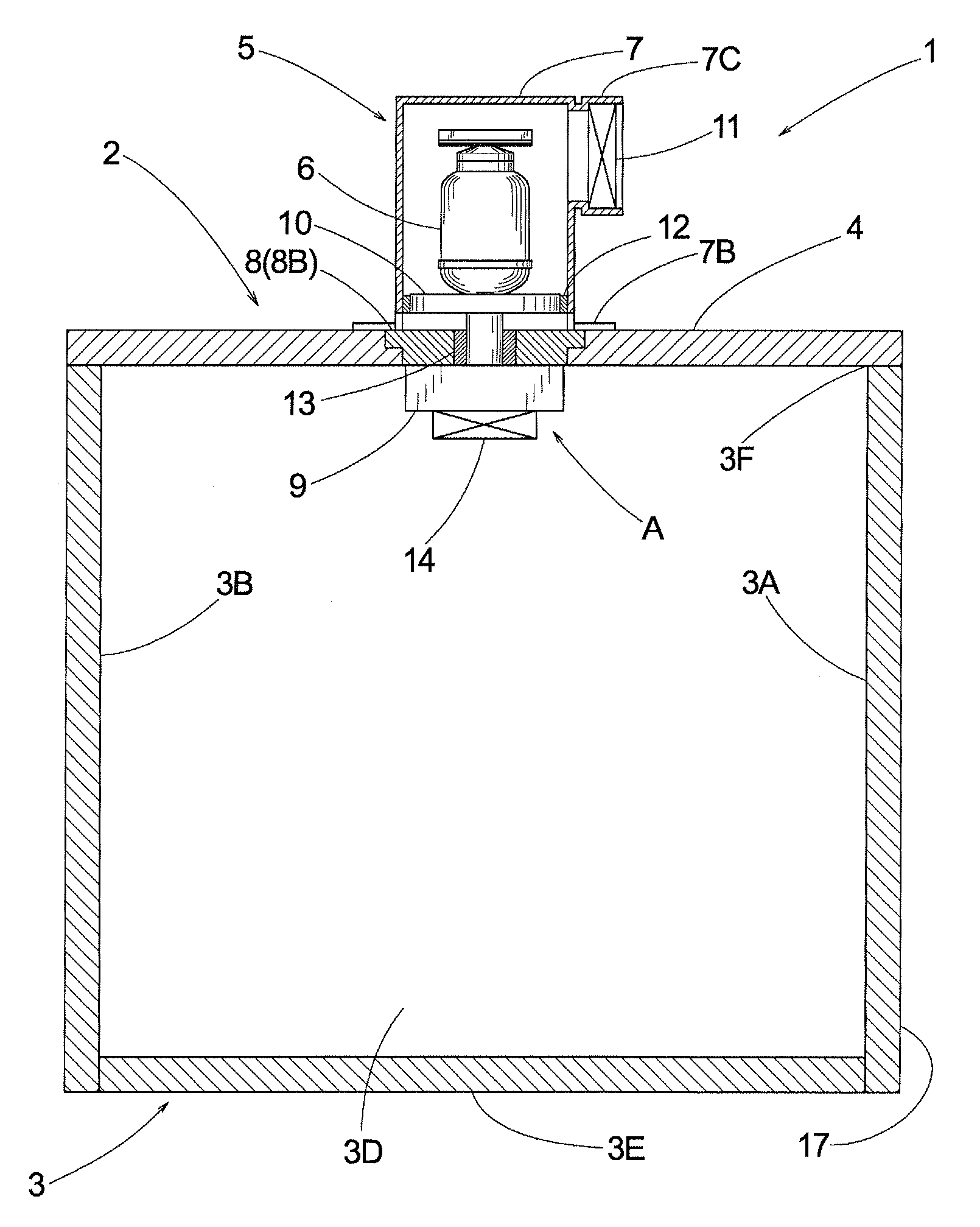

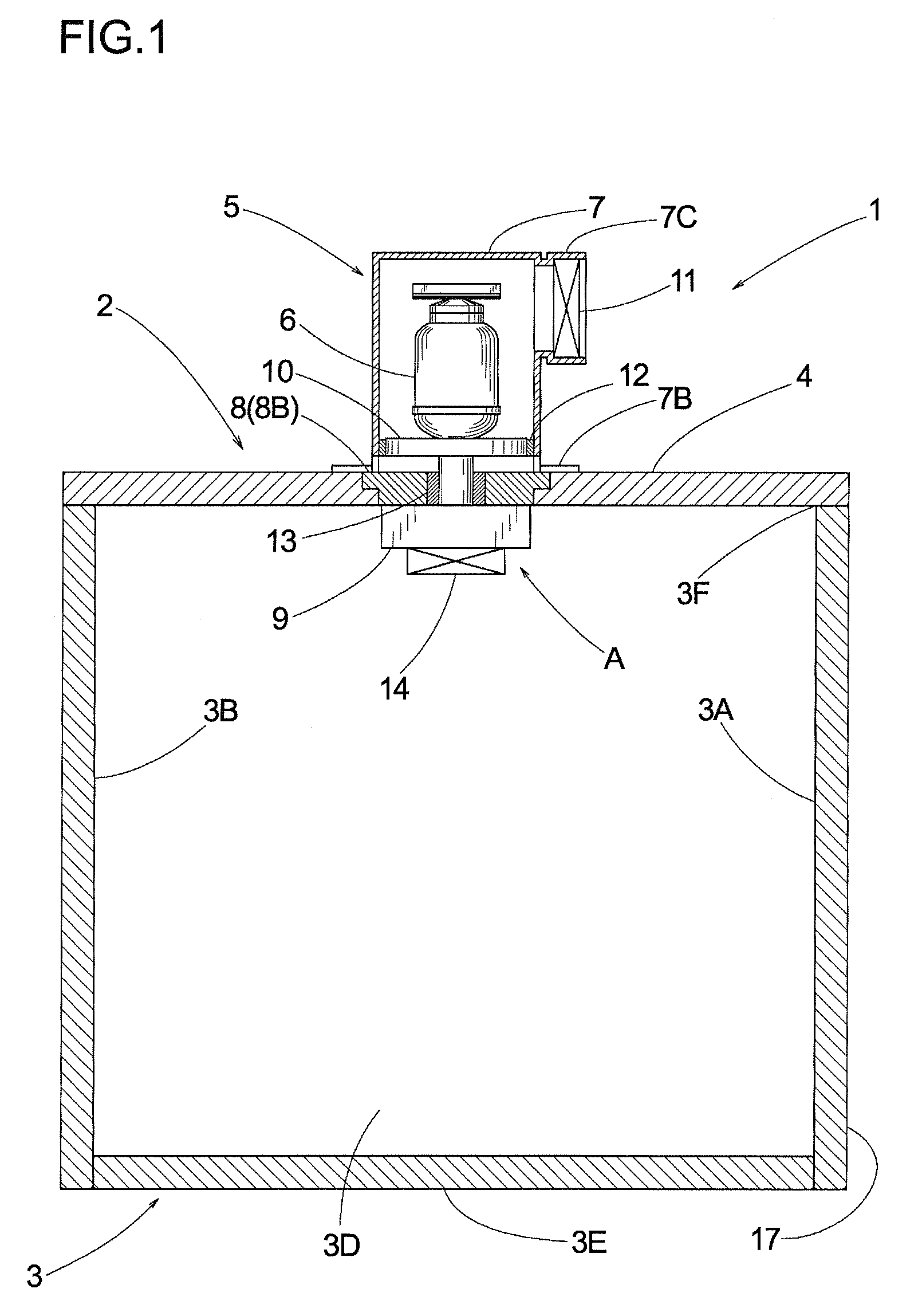

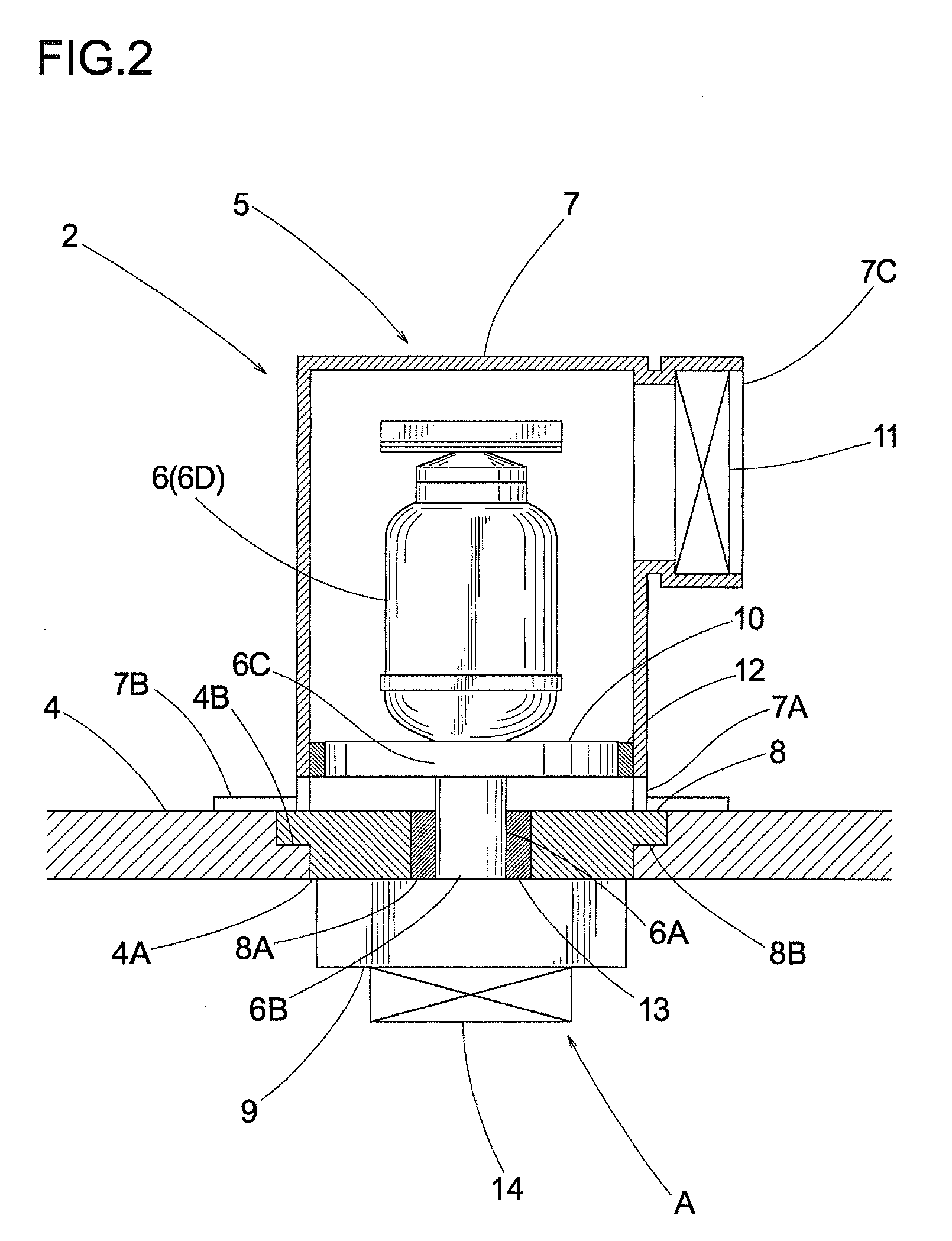

[0053]the present invention will now be explained with reference to FIGS. 1 to 4. Reference number 1 denotes a storage container, and the storage container 1 comprises a temperature controlling unit 2 and an insulating container 3.

[0054]The temperature controlling unit 2 comprises a lid 4 formed with a through-hole 4A in a substantial center thereof, and a temperature controlling subunit 5. The lid 4 is made of an insulative foam synthetic resin in a tabular shape, in a single-piece manner, and its entire surface is covered with an infrared reflection film as an infrared reflection layer. A step member 4B is formed on the through-hole 4A, and a later described base 8 of the temperature controlling subunit 5 is placed on the step member 4B. The temperature controlling subunit 5 comprises a Stirling refrigerator 6 as a temperature controlling device, a casing 7 for containing the Stirling refrigerator 6, and the base 8 for supporting the Stirling refrigerator 6 and the casing 7. The S...

second embodiment

[0060]Next, how to assemble the temperature controlling unit 21 of the second embodiment will now be explained. First, the temperature controlling subunit 23 is assembled. To be more precise, the heat exhausting sink 10 is attached to the heat exhausting portion 6C of the Stirling refrigerator 6, the heat conductive block 26 is attached to the heat absorbing portion 6B of the cylindrical portion 6A, and the outer circumferences of the heat absorbing portion 6B and the heat conductive block 26 are covered with the insulating material 28 and the sealing member 29. The sealing member 12 is attached to the circumference of the heat exhausting sink 10, the Stirling refrigerator 6 is laterally accommodated in the casing 24. At this time, the heat conductive block 26 is allowed to pass through the through-hole 24D. The fan 11 is attached to the exhausting opening 24C of the casing 24. The casing 24 accommodating the Stirling refrigerator 6 is attached to the base 25 by the attachment membe...

third embodiment

[0063]Next, the present invention will now be explained with reference to FIG. 6. The same structure portions as the aforementioned embodiments are denoted by the same reference numbers, and explanations thereof will be omitted. Explanations of the similar effectiveness will be also omitted here. Reference number 30 denotes a storage container, and the storage container 30 comprises a temperature controlling unit 31 and a lid 32. The lid 32 is made of an insulative foam synthetic resin in a tabular shape, in a single-piece manner, and its entire surface is covered with an infrared reflection film as an infrared reflection layer. The lid 32 is openably and closably attached to an opening 33F of a later described insulating container 33 which constitutes the temperature controlling unit 31.

[0064]The temperature controlling unit 31 comprises an insulating container 33 and the temperature controlling subunit 23. The insulating container 33 is so structured as to include a right wall 33A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com