Method and device for preparing liquid CO2 (carbon diode) by cold energy of LNG (liquefied natural gas)

A liquid carbon dioxide and dry ice technology, applied in refrigeration and liquefaction, liquefaction, lighting and heating equipment, etc., can solve the problems of low energy consumption of the system, not involving full utilization of LNG gasification cooling energy, etc., to achieve low energy consumption and utilization rate High and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

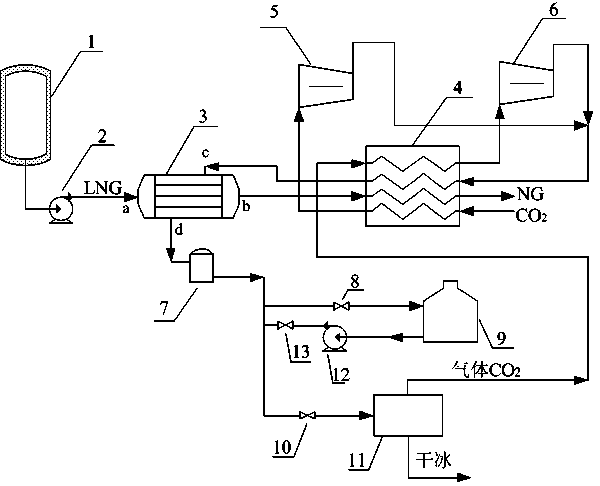

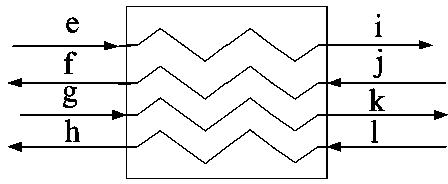

[0032] Refer to attached figure 1 , a process for preparing liquid carbon dioxide and dry ice by using the cold energy of LNG, comprising the following steps: turn on the low-temperature LNG pump 2, LNG at 120kg / h and -162°C is output from the LNG storage tank 1, and enters the shell-and-tube exchange through the LNG pump 2 Heater 3 with 200 kg / h, -40°C, 0.6MPa of CO 2 Heat exchange, LNG through the tube, CO 2 On the shell side, LNG heats up and gasifies into low-temperature gaseous natural gas, then enters the low-temperature natural gas heating channel of the multi-flow plate-fin heat exchanger 4, heats up to a normal temperature of 25°C, and enters the downstream pipeline network to supply gas user. 150 kg / h 25℃, 0.1MPa CO 2 The raw material gas enters the CO of the multi-flow plate-fin heat exchanger 4 2 Raw material gas cooling channel, heat exchange and cooling to -40°C low-temperature CO 2 , into the first compressor 5 after being compressed, the temperature rises,...

Embodiment 2

[0038] Refer to attached figure 1 , a process for preparing liquid carbon dioxide and dry ice by using the cold energy of LNG, comprising the following steps: turn on the low-temperature LNG pump 2, LNG at 140kg / h and -162°C is output from the LNG storage tank 1, and enters the shell-and-tube type exchange through the LNG pump 2 Heater 3 with CO at 200 kg / h, -30°C, 1.0MPa 2 Heat exchange, LNG through the tube, CO 2 On the shell side, LNG heats up and gasifies into low-temperature gaseous natural gas, then enters the low-temperature natural gas heating channel of the multi-flow plate-fin heat exchanger 4, heats up to a normal temperature of 25°C, and enters the downstream pipeline network to supply gas user. 155 kg / h 25°C, 0.1MPa CO 2 The raw material gas enters the CO of the multi-flow plate-fin heat exchanger 4 2 Raw material gas cooling channel, heat exchange and cooling to -30°C low-temperature CO 2 , into the first compressor 5 after being compressed, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com