Apparatus for and method of processing substrate

a substrate and processing apparatus technology, applied in the direction of chemistry apparatus and processes, cleaning processes and apparatus, cleaning using liquids, etc., can solve the problems of requiring apparatus costs, collapsing adjacent protruding portions,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first preferred embodiment

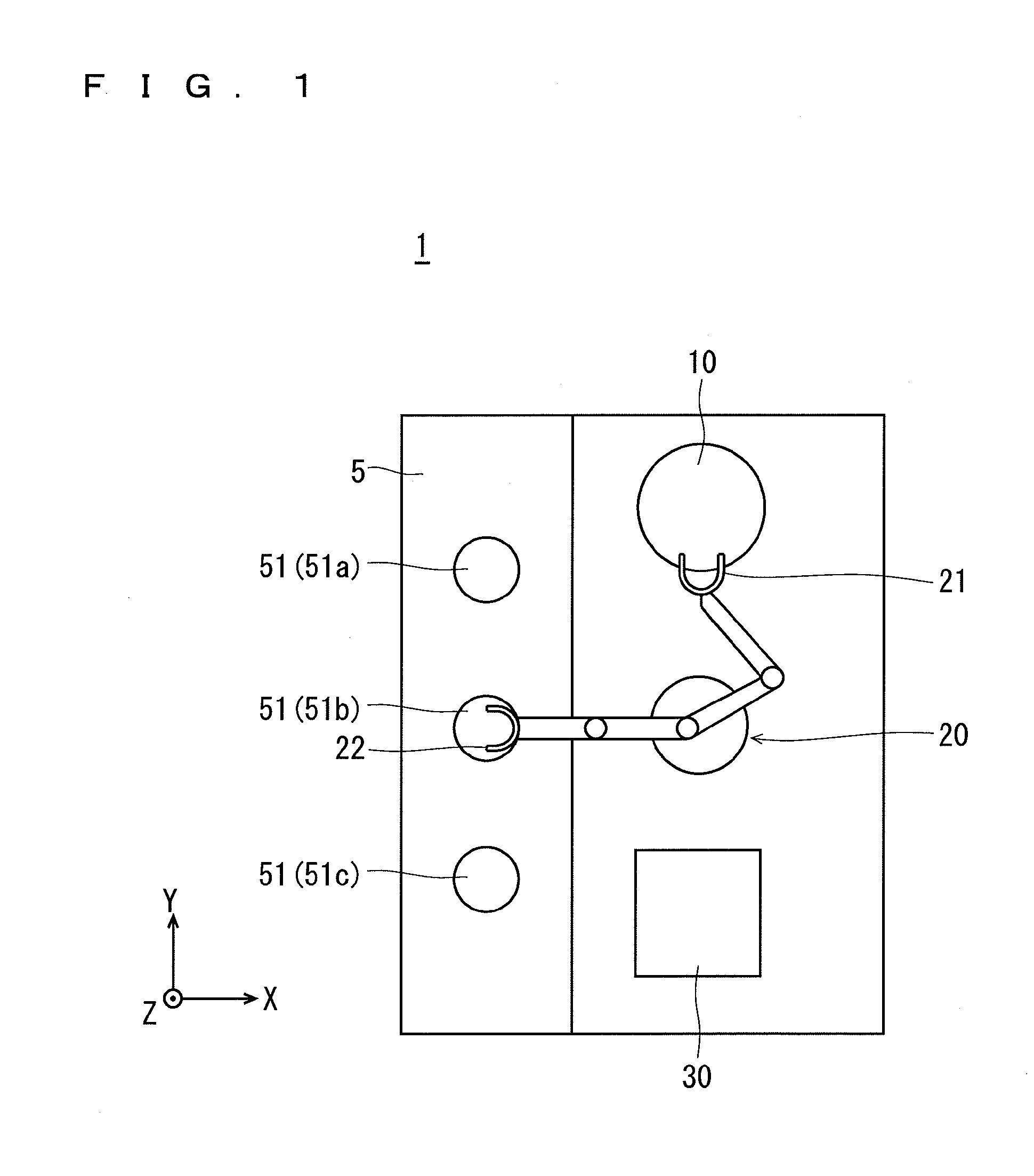

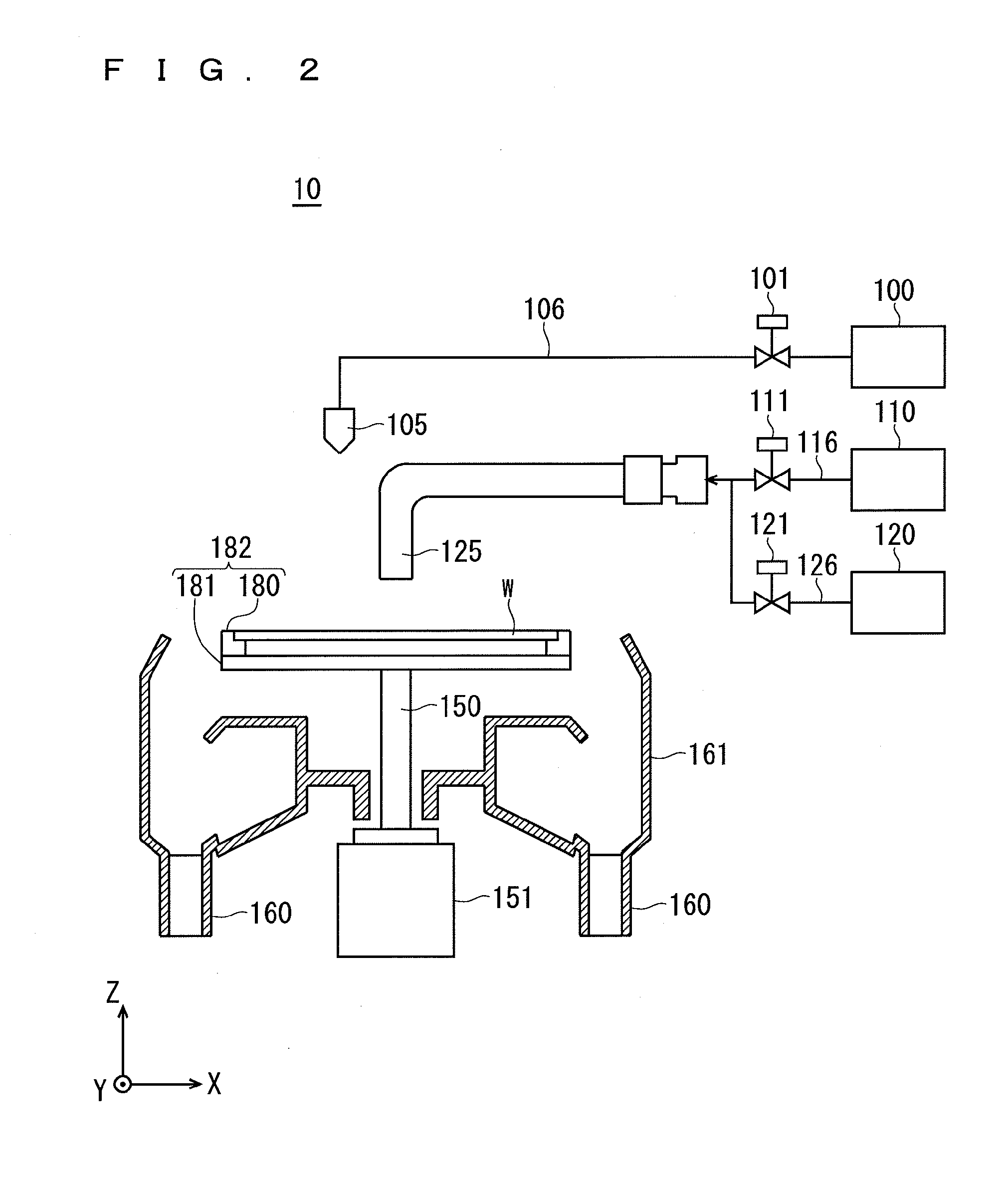

[0022]A substrate processing apparatus 1 as shown in FIG. 1 is a system of process units which is used, for example, in the course of a developing process of a semiconductor substrate W for use as a material of a semiconductor device, and which performs a cleaning process and a drying process after the developing process. The substrate processing apparatus 1 principally includes a substrate station 5, a transfer unit 20, a developer unit 10, and a dryer unit 30. The substrate processing apparatus 1 to be described below is configured as, but not limited to, a single-substrate type processing system for serially processing wafers or substrates W, and may be configured as a batch-type processing system.

[0023]The substrate station 5 includes a plurality of cassettes 51 (in this preferred embodiment, three cassettes 51a, 51b and 51c) placed thereon. A partition wall divides the developer unit 10 and the dryer unit 30 from each other. Substrates W subjected to an exposure process are sto...

second preferred embodiment

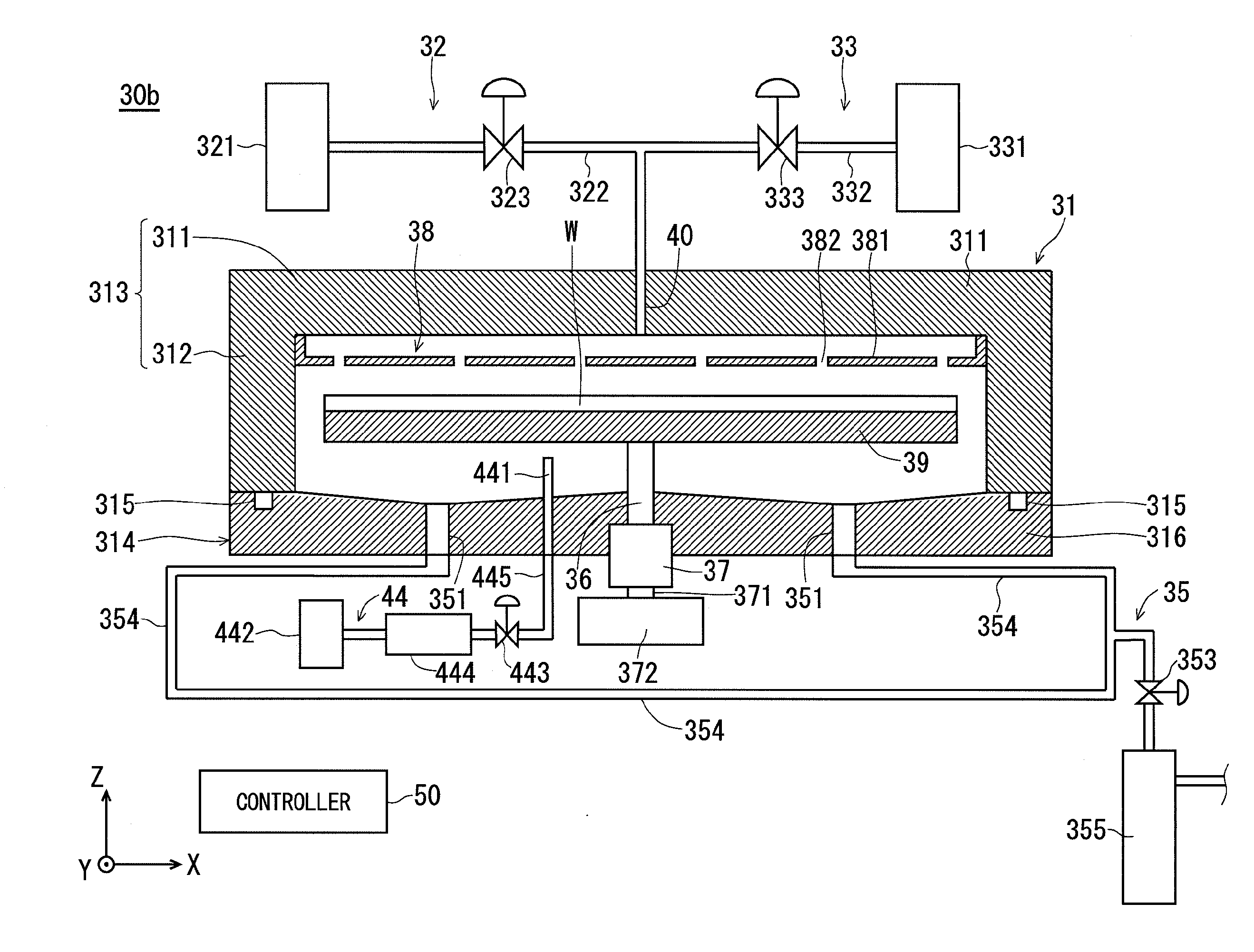

[0071]Next, a dryer unit 30b according to a second preferred embodiment of the present invention will be described with reference to FIGS. 13 and 14. Like reference numerals and characters are used in the second preferred embodiment to designate components identical with those of the first preferred embodiment described above, and only differences from the dryer unit 30 of the first preferred embodiment will be described. The sublimation material for use in the second preferred embodiment is carbon dioxide, as in the first preferred embodiment.

[0072]The liquid carbon dioxide lc covering the surface of the substrate W placed in the dryer chamber 31 according to the first preferred embodiment is solidified by cooling. According to the second preferred embodiment, the liquid carbon dioxide lc is solidified by decreasing the pressure in the dryer chamber 31 in an adiabatic state.

[0073]As shown in FIG. 13, the dryer unit 30b according to the second preferred embodiment is configured such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com