A color wheel module, light source system and projection system

A color wheel and module technology, applied in the field of projection, can solve the problems affecting the conversion efficiency of the color wheel and the internal heat cannot be effectively discharged, and achieve the effects of reducing obstacles, improving conversion efficiency, and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

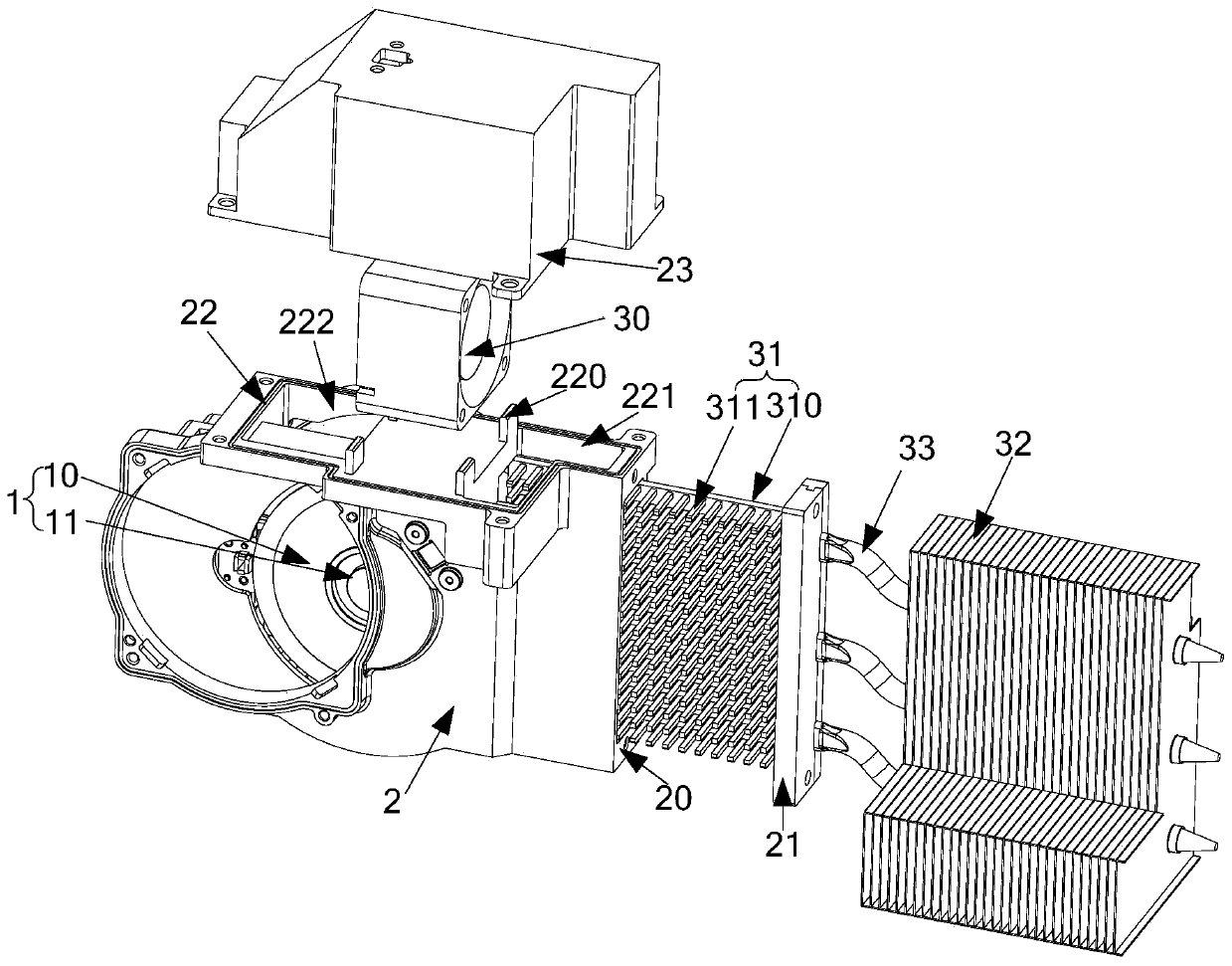

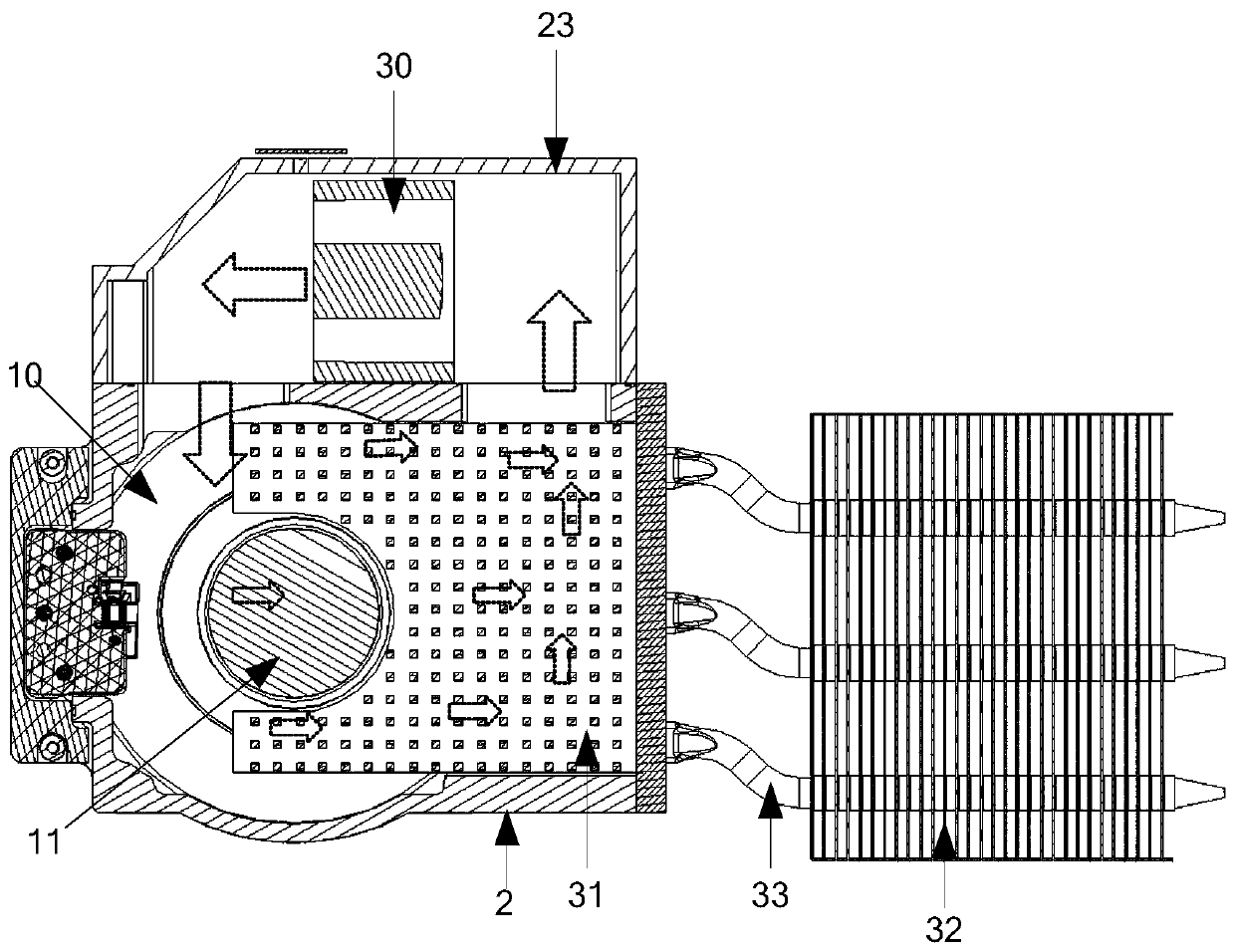

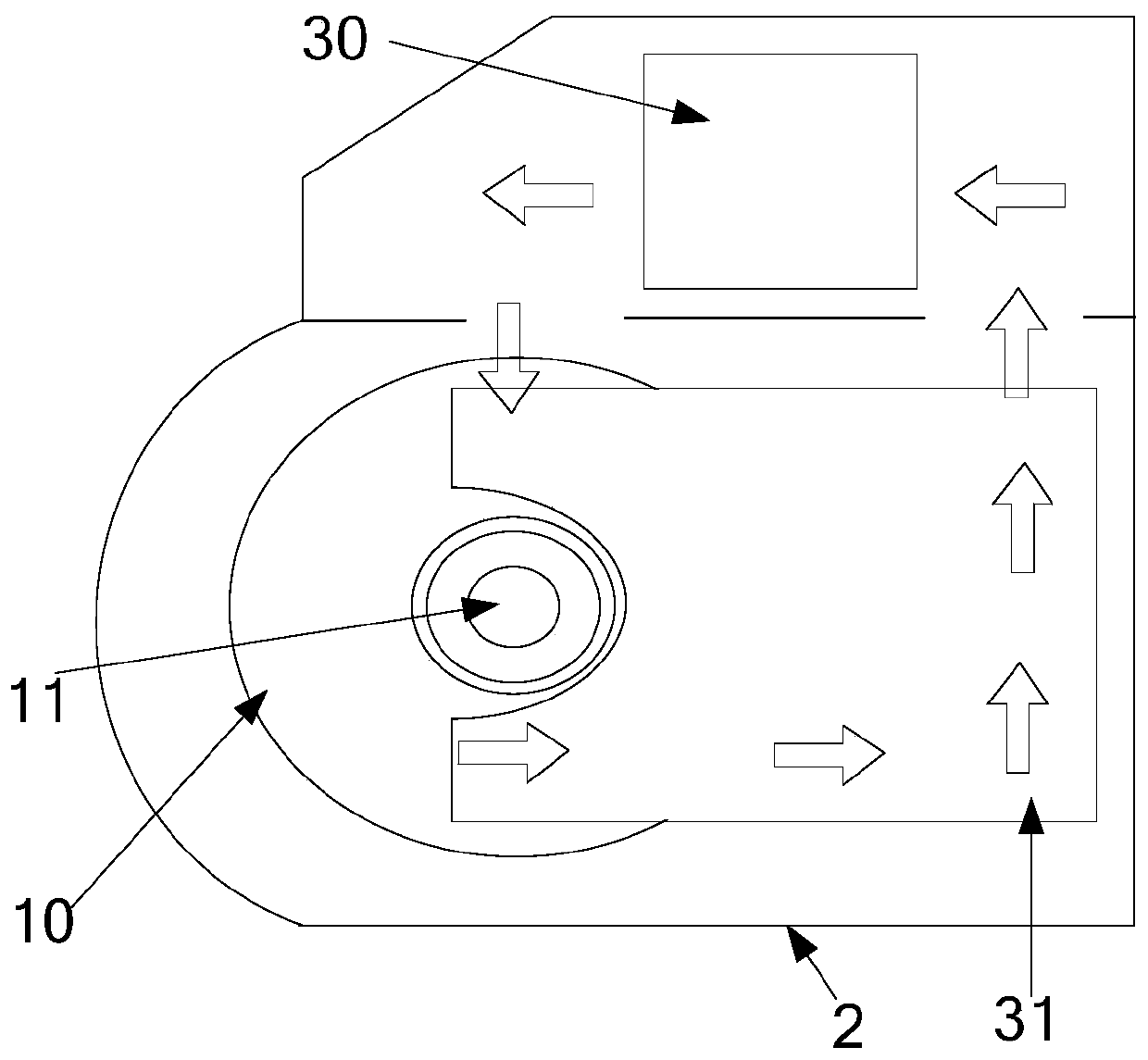

[0048] This embodiment provides a color wheel module, such as figure 1 and figure 2 As shown, the color wheel module includes a color wheel 1, a color wheel housing 2 and a cooling module. The color wheel 1 includes a color wheel disc 10 with a wavelength conversion material and a driving device for driving the color wheel disc 10 to rotate, and the driving device includes a color wheel shaft 11 and a motor and the like. The heat dissipation module includes a fan 30 , a first heat dissipation assembly 31 and a second heat dissipation assembly 32 .

[0049] Wherein, the interior of the color wheel housing 2 has an air circulation channel, the color wheel 1, the fan 30 and the first heat dissipation assembly 31 are all arranged in the air circulation channel inside the color wheel housing 2, and the fan 30 is arranged in the air circulation channel. In the cold air flow section of the channel, the first cooling assembly 31 is arranged on the hot air flow section of the air circ...

Embodiment 2

[0071] This embodiment provides a color wheel module. The structure of the color wheel module in this embodiment is substantially the same as that in Embodiment 1, both including a color wheel 1, a color wheel housing 2 and a heat dissipation module. , the heat dissipation modules all include a fan 30, a first heat dissipation assembly 31 and a second heat dissipation assembly 32, the difference is that, as Figure 4 and Figure 5 As shown: the airflow generated by the fan 30 in this embodiment circulates along the Japanese-shaped airflow circulation channel, the fan 30 is fixed on the first heat dissipation assembly 31, and the fan 30 and the first heat dissipation assembly 31 are fixed on the same side of the color wheel 1 .

[0072] Such as Figure 4 As shown, one side of the color wheel housing 2 in this embodiment has a first opening 24 and a cover plate 25 sealing the first opening 24; the fan 30 and the first cooling assembly 31 enter the color wheel housing through the...

Embodiment 3

[0079] This embodiment provides a color wheel module. The structure of the color wheel module in this embodiment is basically the same as that in Embodiment 2, both including a color wheel 1, a color wheel housing 2 and a heat dissipation module. , the heat dissipation modules all include a fan 30, a first heat dissipation assembly 31 and a second heat dissipation assembly 32, the difference is that, as Figure 6 and Figure 7 As shown, the fan 30 is located between the first heat dissipation component 31 and the color wheel 1 , and the airflow generated by the fan 30 circulates along the zigzag or zigzag airflow circulation channel.

[0080] Such as Figure 6 As shown, one side of the color wheel housing 2 in this embodiment has a first opening 26 and a cover plate 27 sealing the first opening 26; the first heat dissipation assembly 31 enters the interior of the color wheel housing 2 through the first opening 26; The fan 30 is fixed between the first cooling assembly 31 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com