Production technology of mini-jacquard weft elastic yarn-dyed fabric made of aloe fiber

A technology of small jacquard weft elastic and aloe fiber, which is applied in the field of textile fabrics, can solve the problems of insufficient environmental protection and lack of health care functions, and achieve the effects of improving moisture absorption capacity, improving flexibility, and increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

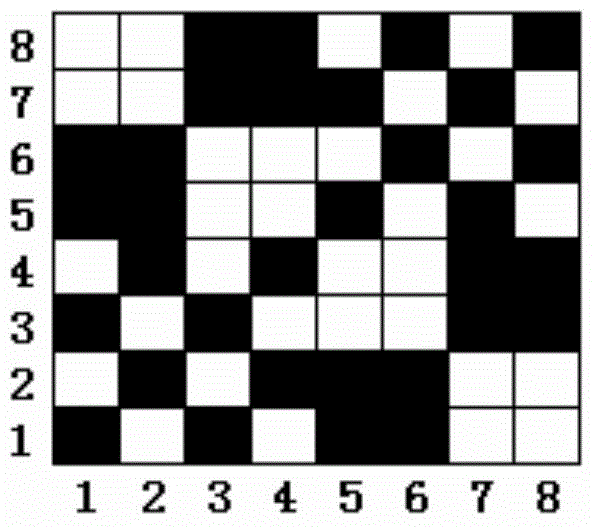

Image

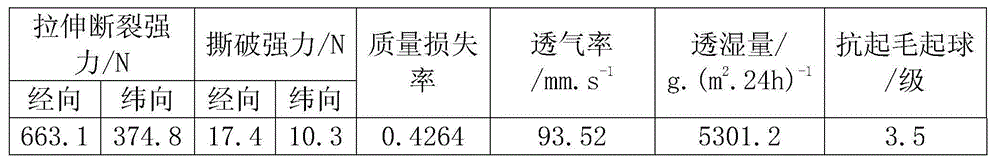

Examples

specific Embodiment 1

[0028] A production process of aloe fiber dobby weft elastic yarn-dyed fabric, comprising the following steps: winding process - warping process - sizing process - weaving process - finishing.

[0029] In the winding process step, the HS-101C type winding machine is adopted, the winding speed is 600m / min, the winding tension is 0g, and the bobbin winding density is 0.40g / cm 3 .

[0030] In the warping process steps, a GA124H high-speed batch warping machine is used for warping, the arrangement of the distribution shafts is 600×5+624×5, and the winding density is 0.46g / cm 3 , the warping speed is 600m / min.

[0031] In described sizing process step, adopt GA308 type sizing machine to carry out sizing, size formula is as follows: animal glue 60kg, carboxymethyl cellulose derivative (CMC) 10kg, glycerol 3kg, JFC3kg; Animal glue and carboxymethyl cellulose Cellulose derivatives (CMC) are used as the main size, which is coated and soaked on the surface and inside of the yarn durin...

specific Embodiment 2

[0042] A production process of aloe fiber dobby weft elastic yarn-dyed fabric, comprising the following steps: winding process - warping process - sizing process - weaving process - finishing.

[0043] In the winding process step, the HS-101C type winding machine is adopted, the winding speed is 800m / min, the winding tension is 15g, and the bobbin winding density is 0.46g / cm 3 .

[0044] In the warping process steps, a GA124H high-speed batch warping machine is used for warping, the arrangement of the distribution shafts is 600×5+624×5, and the winding density is 0.52g / cm 3 , the warping speed is 800m / min.

[0045] In described sizing process step, adopt GA308 type sizing machine to carry out sizing, size formula is as follows: animal glue 60kg, carboxymethyl cellulose derivative (CMC) 10kg, glycerol 3kg, JFC3kg; Animal glue and carboxymethyl cellulose Cellulose derivatives (CMC) are used as the main size, which is coated and soaked on the surface and inside of the yarn duri...

specific Embodiment 3

[0056] A production process of aloe fiber dobby weft elastic yarn-dyed fabric, comprising the following steps: winding process - warping process - sizing process - weaving process - finishing.

[0057] In the winding process step, the HS-101C type winding machine is adopted, the winding speed is 700m / min, the winding tension is 10g, and the bobbin winding density is 0.43g / cm 3 .

[0058] In the warping process steps, a GA124H high-speed batch warping machine is used for warping, the arrangement of the distribution shafts is 600×5+624×5, and the winding density is 0.49g / cm 3 , the warping speed is set to 700m / min.

[0059] In described sizing process step, adopt GA308 type sizing machine to carry out sizing, size formula is as follows: animal glue 60kg, carboxymethyl cellulose derivative (CMC) 10kg, glycerol 3kg, JFC3kg; Animal glue and carboxymethyl cellulose Cellulose derivatives (CMC) are used as the main size, which is coated and soaked on the surface and inside of the ya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com