Bakelite corrugated board made of preliminarily woven components with flow guide layers and method for manufacturing bakelite corrugated board

A technology of a diversion layer and a pre-woven piece, which is applied in the field of bakelite corrugated board and its manufacturing, can solve the problems of mechanical properties decline, easy to burn, etc., and achieve the effects of strong anti-aging performance, good support performance, and uniform longitudinal and transverse strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The present invention provides the preparation steps of the bakelite corrugated board as follows:

[0037] 1. Preparation of the resin system: first blend the phenolic resin, halogen-free flame retardant, diluent, pigment, and mold release agent. The blending tank is kept at a constant temperature, and the temperature is kept at 85 degrees to keep the resin material well Fluidity will not react cross-linking.

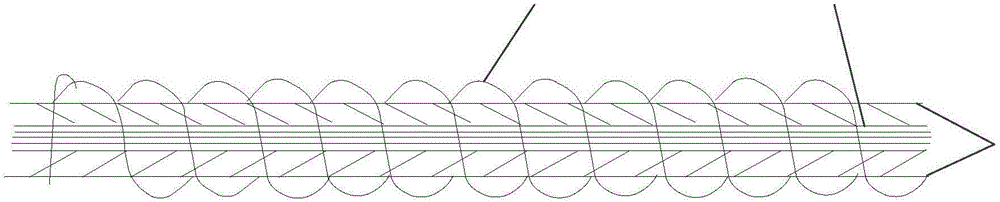

[0038] 2. Manufacture of pre-woven parts: Weave the above-mentioned carbon fiber and glass fiber into a cylindrical shape through a loom, soak the resin material, wrap the polyester surface mat and shape it through the pre-forming mold.

[0039] 3. Curing molding: pull the above pre-woven parts into the metal mold cavity, and perform three-stage temperature-controlled curing. The temperatures of the three stages are 140-170°C, 180-240°C, and 160-190°C. At the end of the metal mold, the profile is dragged by a crawler tractor.

Embodiment 1

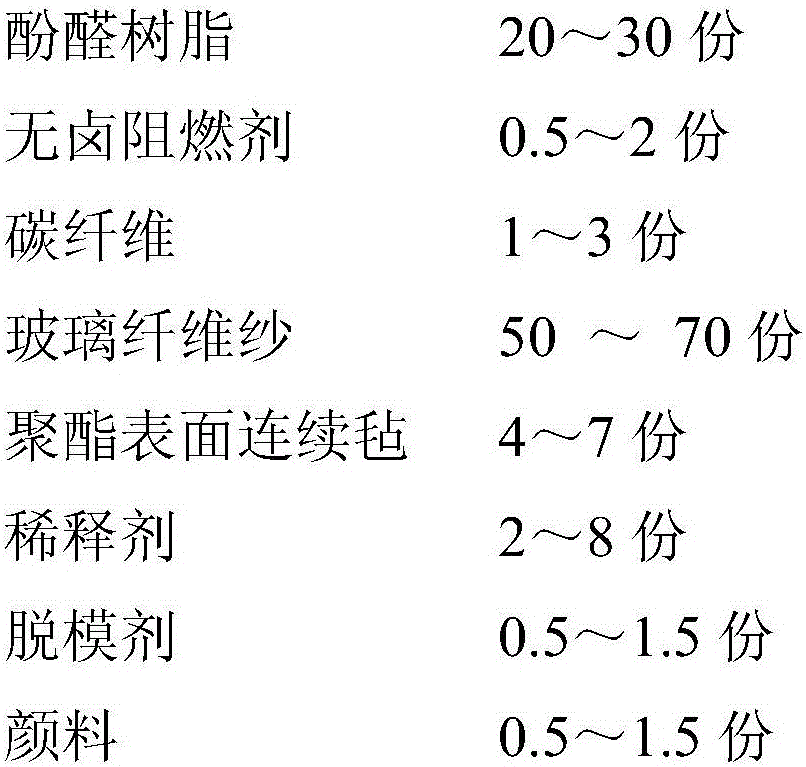

[0041] A fiber-reinforced phenolic resin composite material roof (wall) corrugated board, which is made of the following components by weight through a pultrusion process, and the temperature of the pultrusion die is 140-280°C:

[0042]

[0043] The preparation steps are as follows:

[0044] 1. Preparation of the resin system: first blend the phenolic resin, halogen-free flame retardant, diluent, pigment, and mold release agent. The blending tank is kept at a constant temperature, and the temperature is kept at 85 degrees to keep the resin material in good condition. Fluidity will not react cross-linking.

[0045] 2. Manufacture of pre-woven parts: Weave the above-mentioned carbon fiber and glass fiber into a cylindrical shape through a loom, soak the resin material, wrap the polyester surface mat and shape it through the pre-forming mold.

[0046] 3. Curing molding: pull the above-mentioned pre-woven parts into the metal mold cavity, and perform three-stage temperature-cont...

Embodiment 2

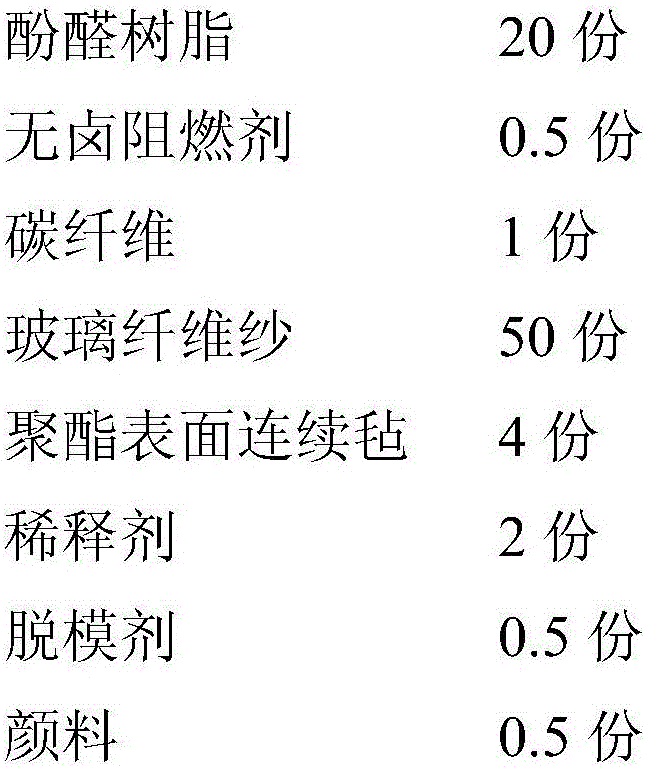

[0048] A fiber-reinforced phenolic resin composite material roof (wall) corrugated board is made of the following components by weight through a pultrusion process, and the temperature of the pultrusion die is 140-280°C:

[0049]

[0050] The preparation steps are as follows:

[0051] 1. Preparation of the resin system: first blend the phenolic resin, halogen-free flame retardant, diluent, pigment, and mold release agent. The blending tank is kept at a constant temperature, and the temperature is kept at 85 degrees to keep the resin material well Fluidity will not react cross-linking.

[0052] 2. Manufacture of pre-woven parts: The manufacture of pre-woven parts: first lay the glass fiber mat in layers, then add the fiber cloth of the diversion layer to the middle layer of the laid glass mat, and then use sewing technology to pass high-strength continuous carbon fiber The glass fiber mat and the fiber cloth of the guide layer are sewed together by silk to obtain a glass fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com