Device and method for producing semifinished products for wind power system rotor blades and rotor blade and wind energy system produced therewith

A technology for rotor blades and wind energy equipment, applied to equipment for manufacturing semi-finished products for wind energy equipment rotor blades and, thereby, the field of rotor blades and wind energy equipment, capable of solving problems such as not being eliminated, and reducing logistical costs , the effect of optimizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

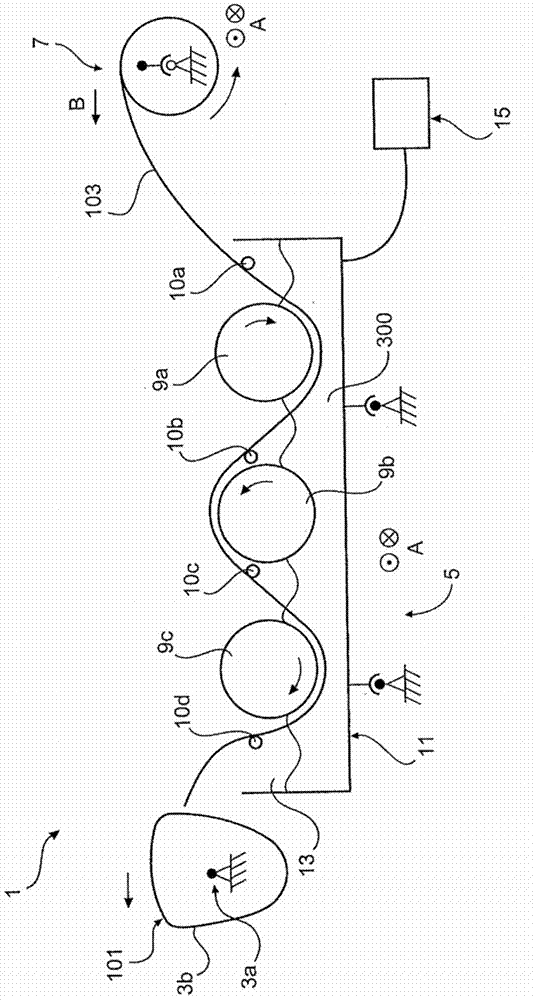

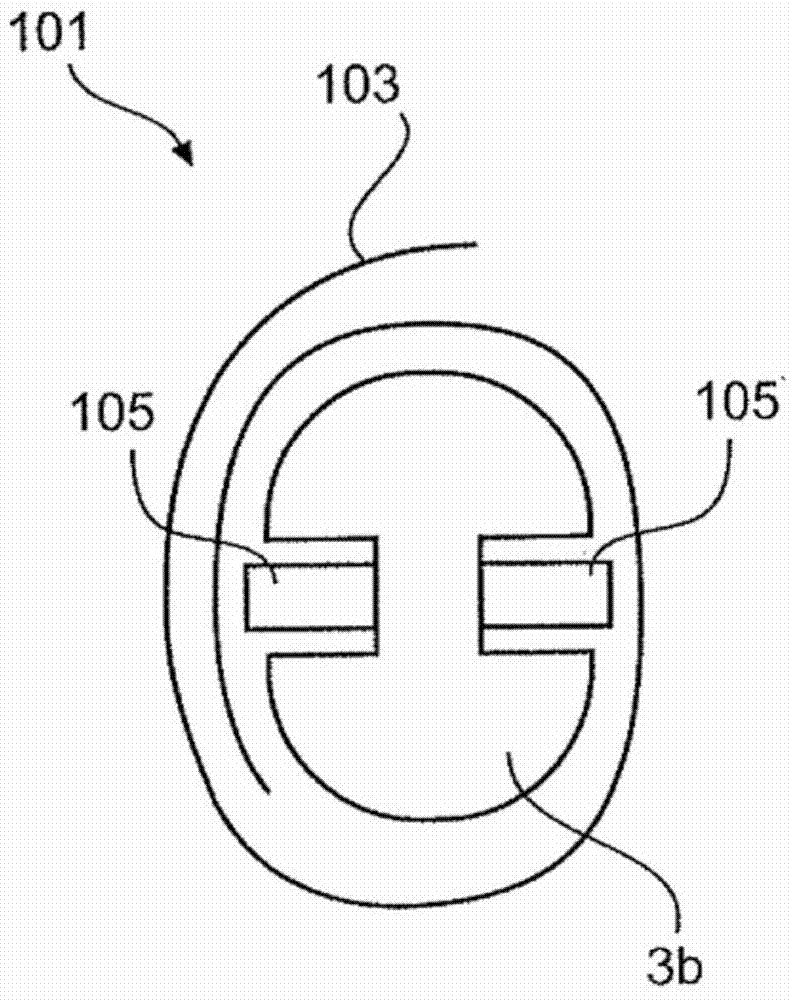

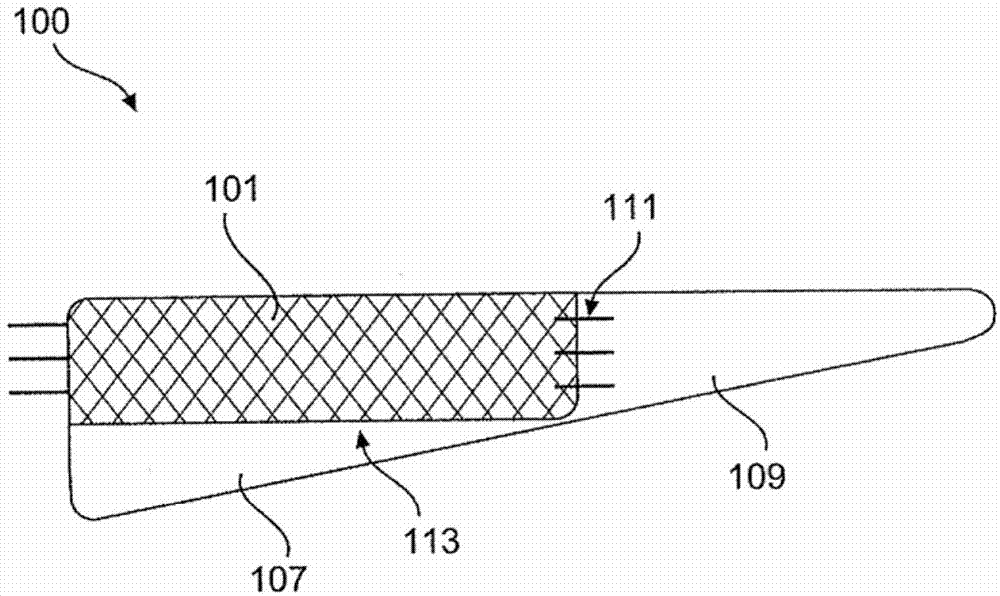

[0051] exist figure 1 An apparatus for manufacturing blade tips according to a preferred embodiment of the present invention is schematically depicted in . The device 1 has a winding mandrel 3a, which is rotatably driven. Fastened to the winding mandrel 3 a is a winding casing 3 b around which the fiber composite material 103 is wound up in a track. The winding mandrel 3a is arranged stationary.

[0052] The device 1 also has a soaking device 5 . The soaking device 5 has a soaking tub 13 with a bottom 11 . A plurality of deflection rollers 9a, b, c are arranged in the infusion device 5 in a spaced manner from the bottom. as indicated in figure 1 As shown in , the distances of the deflection rollers 9 a - c from the base 11 can be chosen to be the same or different depending on which angle the fiber composite material 103 is wound around the deflection rollers 9 a , b , c. Furthermore, the soaking device 5 has a plurality of tensioning rollers 10a, b, c, d, which act on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com