Preparation method of ultrahigh-temperature yeast for making hard liquor

A manufacturing method and ultra-high temperature technology, applied in the field of brewing, can solve the problems of unavailable, high koji product temperature, limiting the nutritional value, taste, taste and other problems of liquor, achieve soft taste, improve koji product temperature, aroma and rich taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

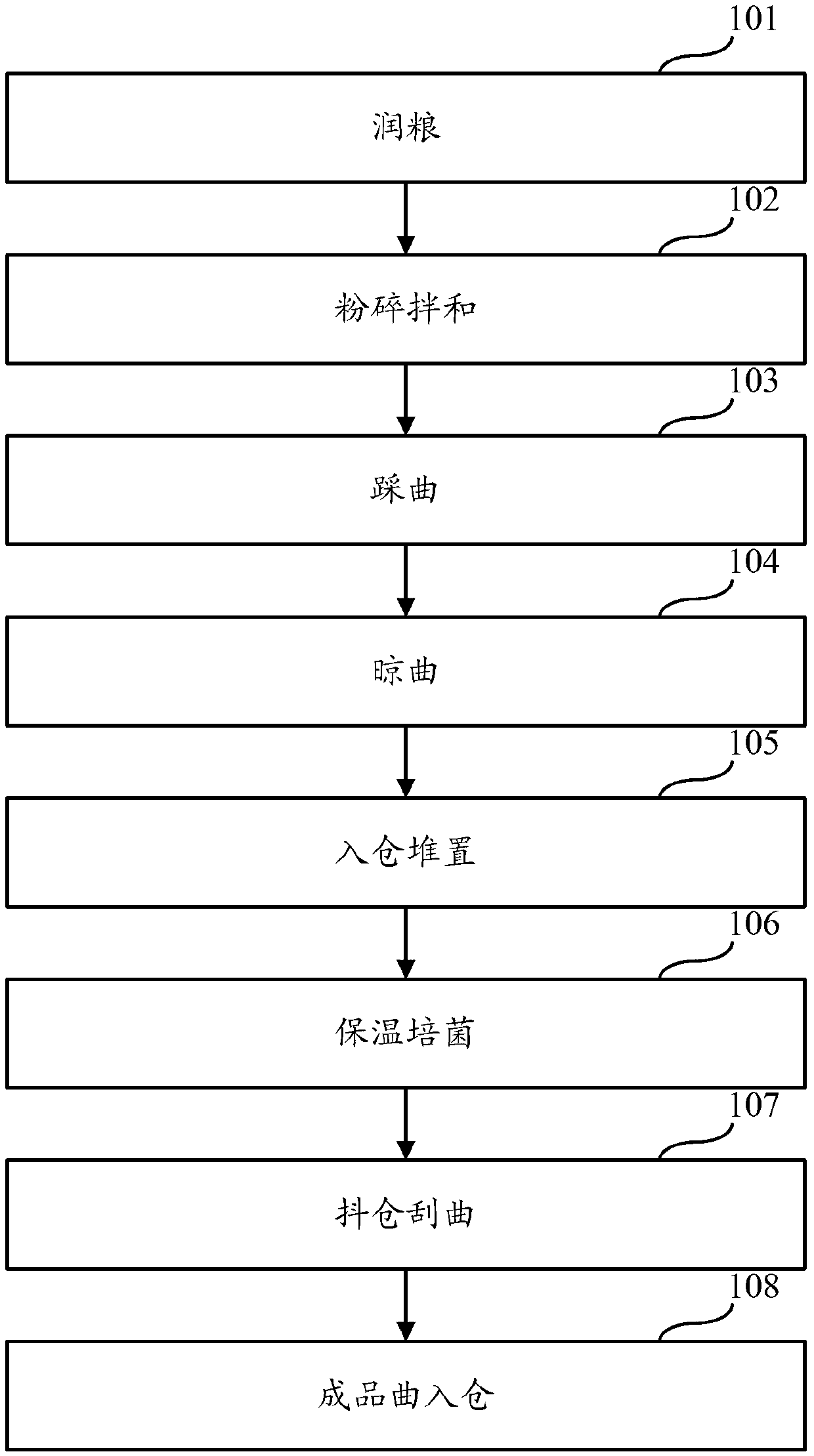

[0049] figure 1 It is a flowchart of a method for manufacturing ultra-high temperature Daqu according to an embodiment of the present invention, including the following steps:

[0050] Step 101, Run grain

[0051] Whole wheat can be used as raw material. In order to make the wheat fully absorb moisture and evenly drenched, it is possible to increase the moisture content of grain moistening in an appropriate amount. The present invention adjusts from 5% to 10% of the total mass of the original raw material to 8% to 12% (preferably 9%); the grain moistening time is extended from the original 10 hours to 15-25 hours (preferably 20 hours). Dig, shift, etc.

[0052] Step 102, breaking and mixing with water

[0053] Add the moistened grain to the koji (pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com