Interlamination reinforced fiber composite material with flow guiding layer and preparation method thereof

A technology of fiber composite material and interlayer reinforcement, which is applied in the field of interlayer reinforced fiber pre-woven parts and its manufacturing in the pultrusion process, interlayer reinforced fiber composite material and its manufacturing field, and can solve the problem of lack of glue and resin difficulty in composite materials. Uniform impregnation, large thickness of fiber preforms, etc., to achieve the effects of easy operation, improved interlayer shear strength, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] For the purpose of full disclosure, the present invention will be further described in detail below in conjunction with examples. It should be understood that the specific embodiments described below are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

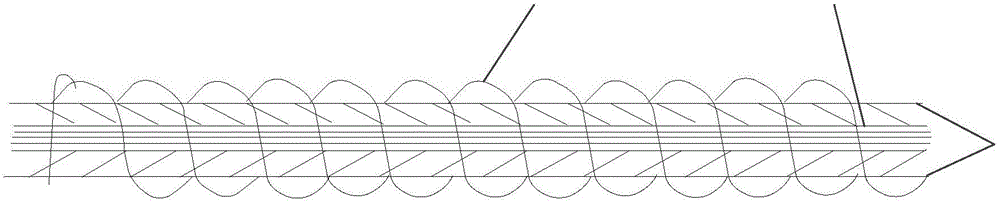

[0028] The interlayer reinforced fiber composite material disclosed in the present invention includes an interlayer reinforced fiber prewoven part and a matrix resin, wherein the interlayer reinforced fiber prewoven part includes a glass mat 1 laid in layers, a flow guide layer fiber cloth 2 and a layer Continuous fibers 3 between layers, and the layered glass mat 1 and fiber cloth 2 of the diversion layer are stitched together by the continuous fibers 3 between layers.

[0029] Using unsaturated resin, vinyl resin and phenolic resin as matrix, interlayer reinforced fiber pre-woven parts can be formed by pultrusion process to make composite materials. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com