Ink fountain for building engineering

A construction engineering and ink fountain technology, which is applied in the field of ink fountains for construction engineering, can solve problems such as unfavorable use and reduction of ink fountains.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

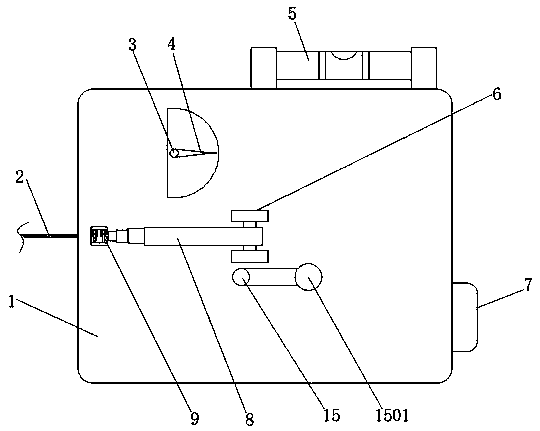

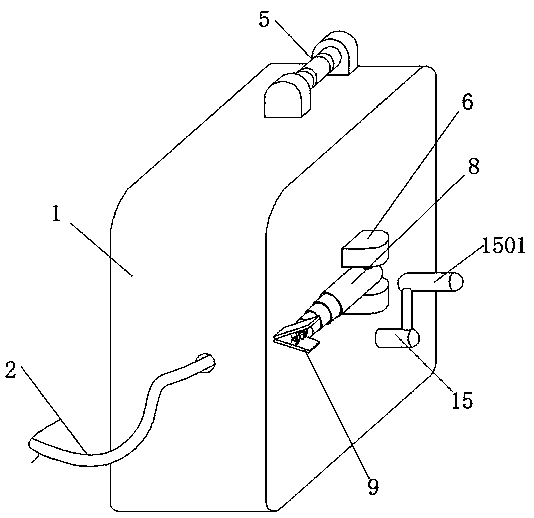

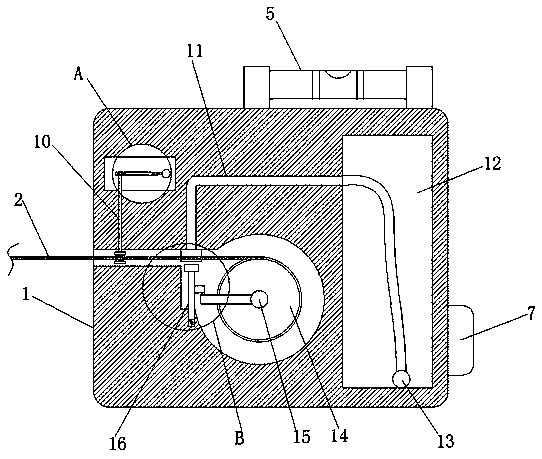

[0034] refer to Figure 1-7 , an ink fountain for construction engineering, comprising a main body 1, an ink tank 12 is provided on one side of the main body 1, and a first cavity is opened on the other side of the main body 1, and the main body 1 is rotatably connected at the inner wall of one side of the first cavity. There is a rotating shaft 15, and the middle part of the rotating shaft 15 is welded with a pulley 14, and the outside of the pulley 14 is wound with an ink line 2. The main body 1 has a first through hole on the inner wall of one side of the first cavity, and the ink line 2 is in the first through hole. extends to the outside of the main body 1, the main body 1 is provided with a second through hole between the first cavity and the ink tank 12, the main body 1 is provided with a cotton thread 11 at the second through hole, and one end of the cotton thread 11 is in the ink tank 12 Inside, the cotton thread 11 can absorb the ink in the ink tank 12 and send it to...

Embodiment 2

[0048] refer to Figure 8-10 , a kind of ink fountain for construction engineering. Compared with Embodiment 1, in order to increase the practicability of the device and prolong the service life of the device, the sponge 20 is provided with rubber pads 26 on both sides of the semicircular groove, and the ink line 2 When in use, it will rub against both sides of the semicircular groove of the sponge 20, especially when the ink line 2 is not parallel, and the rubber pad 26 can prevent the contact between the sponge 20 and the ink line 2, so that the service life of the sponge 20 will be increased .

[0049] When in use, the ink line 2 is pulled, the ink line 2 drives the pulley 14 to rotate, the pulley 14 drives the rotating shaft 15 to rotate, the rotating shaft 15 drives the rotating rod 23 to rotate around the rotating shaft 15, and the rotating rod 23 rotates once to hit the moving block 22 once. Make the moving block 22 move, the moving block 22 drives the push rod 16 to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com