Continuous production method and equipment for composite type sleeper

A production method and composite technology, applied in the field of sleepers, can solve the problems of heavy workload, sleeper failure, and long production cycle, and achieve the effects of simplifying the manufacturing process, increasing the maximum load, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

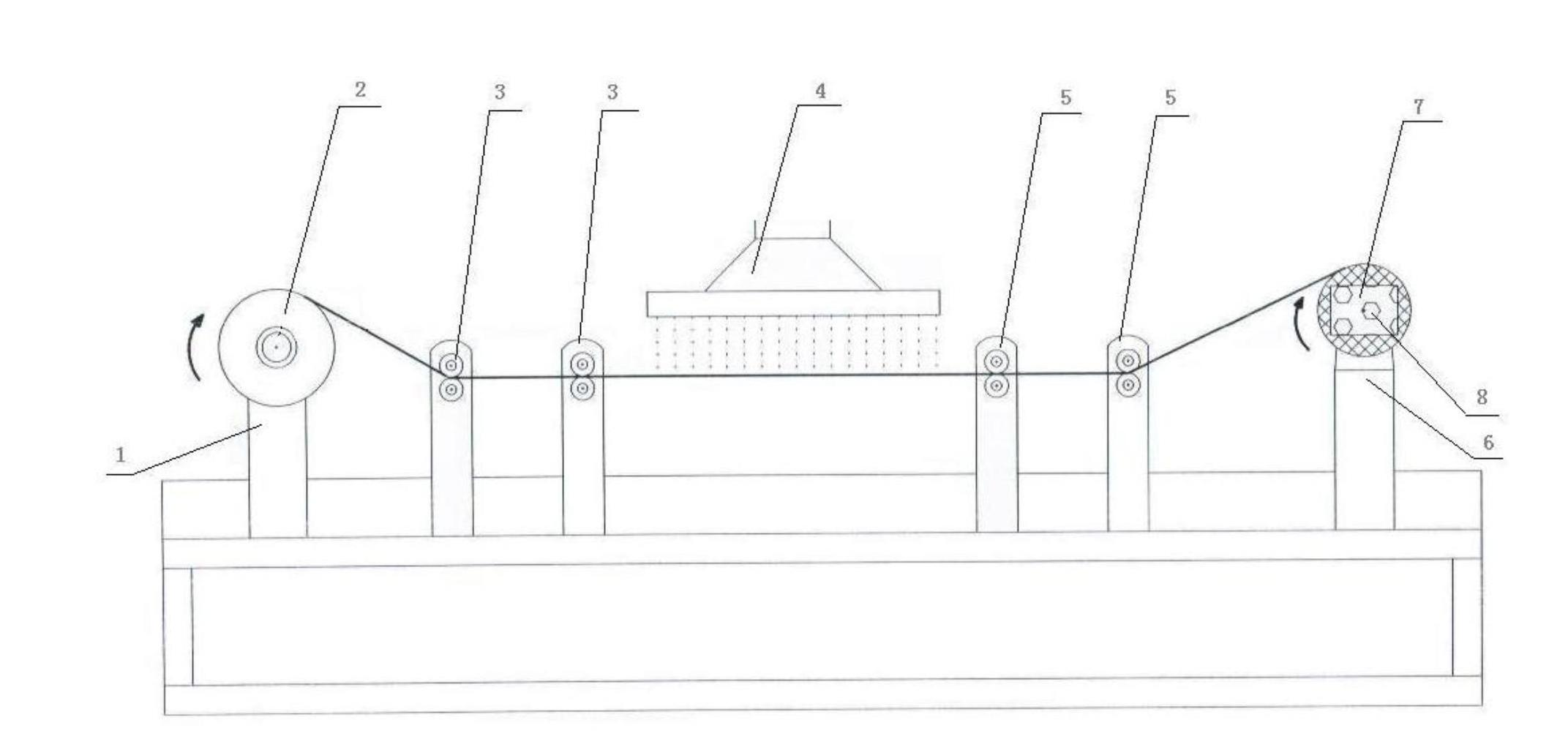

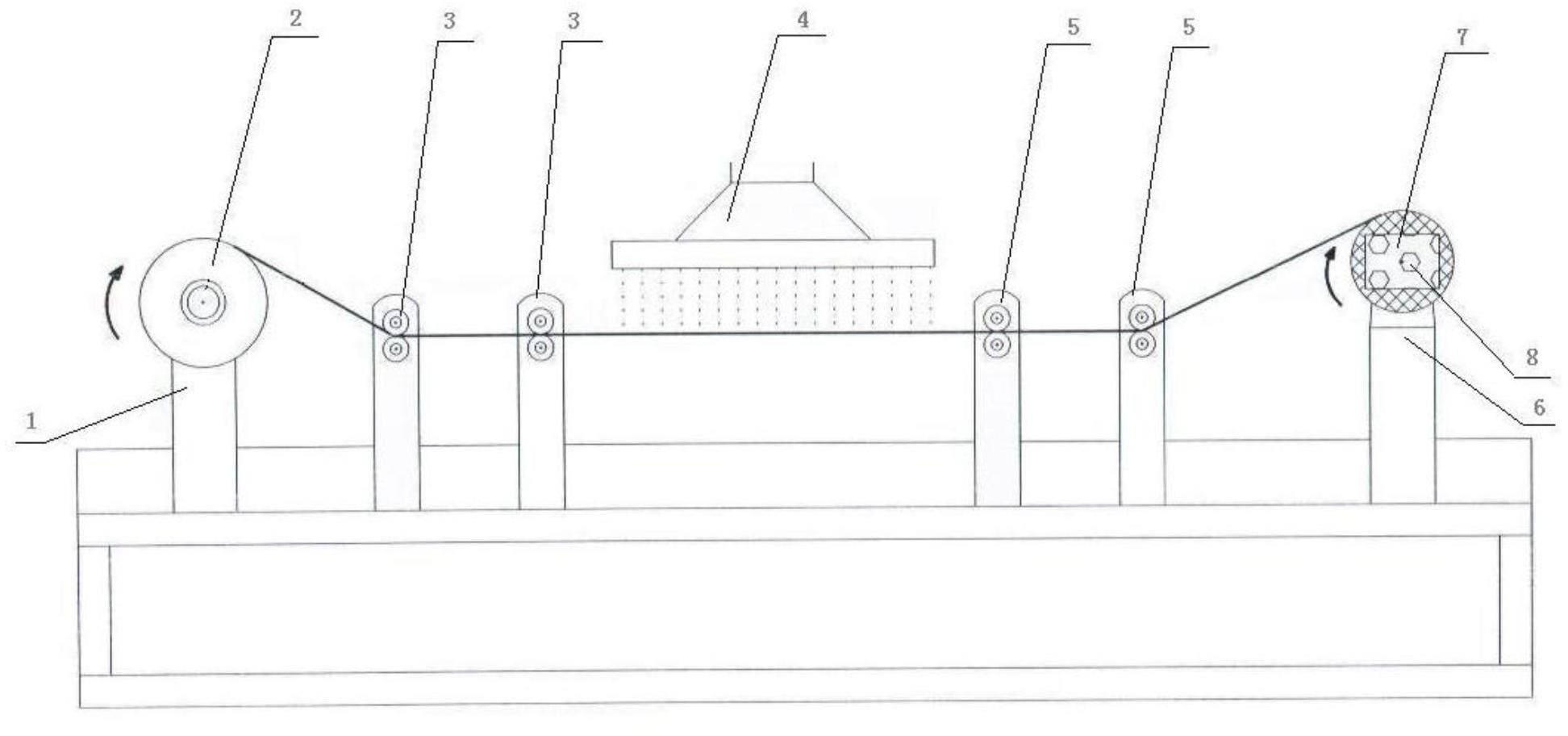

[0051] (1) Production equipment

[0052] Such as figure 1 As shown, the continuous production equipment is provided with a first rotating device 1 , a spreading mechanism 3 , a sprayer 4 , a pair of rollers 5 , and a second rotating device 6 in sequence. A rolled glass fiber multiaxial cloth 2 is placed on the first rotating device 1 , and when the rolled glass fiber multiaxial cloth 2 is driven to rotate by the first rotating device 1 , the glass fiber multiaxial cloth is unfolded. When the glass fiber multiaxial cloth passes through the stretching mechanism 3, the glass fiber multiaxial cloth can be smoothly unfolded and the wrinkles are removed. In order to better unfold and remove the glass fiber multiaxial cloth wrinkles, it can be set Two stretching mechanisms 3. The sprayer 4 is located between the stretching mechanism 3 and the pair of rollers 5 and above the glass fiber multi-axial cloth. Two reservoirs are arranged on the upper end of the sprinkler 4, and the two ...

Embodiment 2

[0059] (1) Production equipment

[0060] The same production equipment as in (1) in Example 1 is adopted, the difference is that: the stretching mechanism 3 is set as one, the counter roller 5 is set as a group, and a reservoir is set at the upper end of the sprinkler 4, and the sprinkler 4 passes through the pipeline Connected to the reservoir, there is no static mixer in the sprinkler 4 either.

[0061] (2) Continuous production method

[0062] The rolled glass fiber twill 2 is placed on the first rotating device 1, and the first rotating device 1 drives the rolled glass fiber twill 2 to rotate to unfold it, and then the glass fiber twill passes through the stretching mechanism 3, and the stretching mechanism 3 Flatten the fiberglass twill to remove wrinkles.

[0063] The stock solution of the uniformly mixed polyurethane resin is stored in the reservoir, which can be directly input into the sprinkler 4, and then evenly sprayed on the surface of the polyurethane resin belo...

Embodiment 3

[0067] (1) Production equipment

[0068] The same production equipment as in (1) in Example 1 was adopted, with the difference that: two stretching mechanisms 3 were set, and six pairs of rollers 5 were set.

[0069] (2) Continuous production method

[0070] The rolled glass fiber grid cloth 2 is placed on the first rotating device 1, and the first rotating device 1 drives the rolled glass fiber grid cloth 2 to rotate to unfold it, and then the glass fiber grid cloth passes through the stretching mechanism 3, The stretching mechanism 3 flatly spreads the glass fiber grid cloth and removes wrinkles.

[0071] The two storages arranged at the upper end of the sprinkler 4, the raw materials stored in one of the storages are polyols, blowing agents, catalysts, flame retardants and anti-aging agents, and the raw materials stored in the other storage are isocyanates, The sprayer 4 is respectively connected to the two storages through pipelines, and the raw materials in the storages...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com