Pipeline penetration structure

A technology for penetrating cabins and pipelines, which is applied in the direction of pipes, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as shortening the service life of the pipeline system, damage to pipeline system components, and affecting the normal operation of equipment, etc., to achieve Improve safety and reliability, protect pipeline structure, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

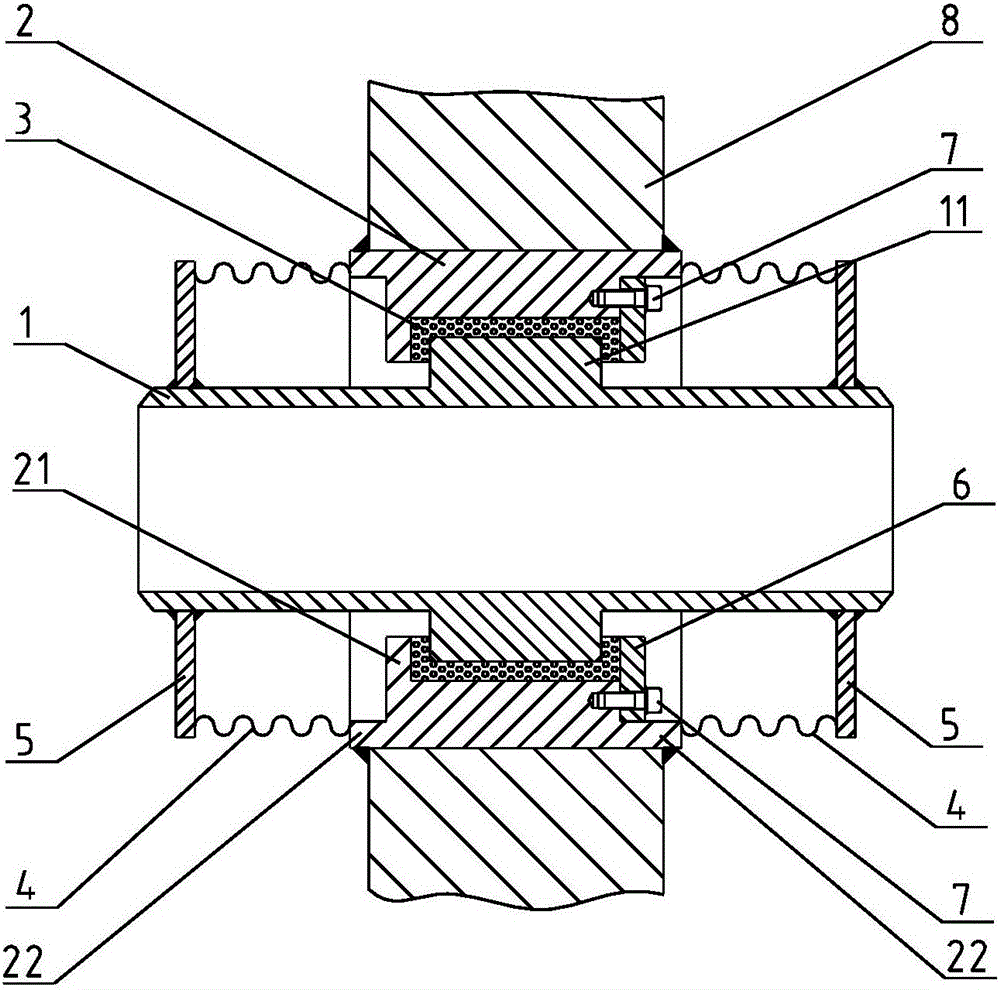

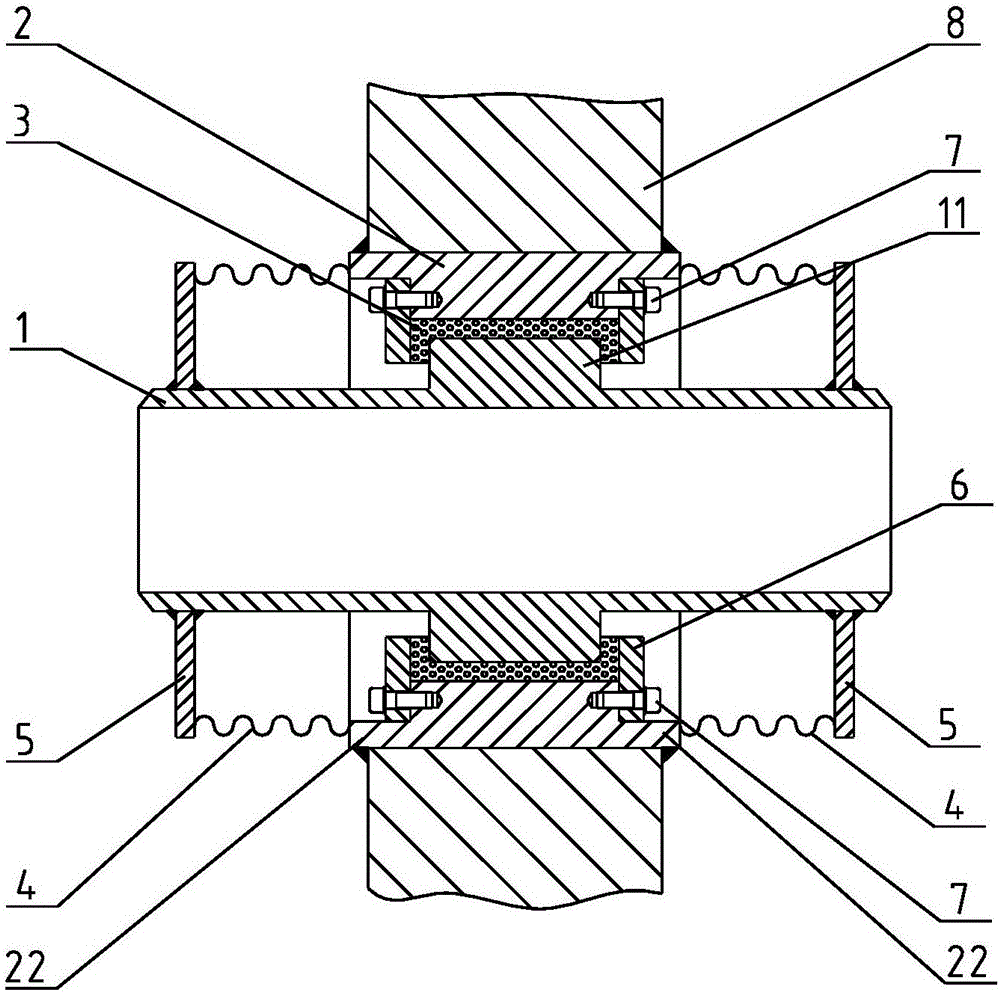

[0027] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a pipeline piercing structure, which includes a transition pipe 1 , a casing 2 , two bellows 4 and a ring plate 5 .

[0028] The casing 2 is sheathed on the transition pipe 1, and an accommodating chamber 3 is formed between the transition pipe 1 and the casing 2, and the accommodating chamber 3 is filled with a damping material. The damping material is metal damping wire or rubber material, and other materials with damping properties can also be used.

[0029] The accommodation cavity 3 is a ring with a "冖" shaped cross section.

[0030] see figure 1 As shown, an embodiment of the present invention is: a protruding annular portion 11 is provided in the middle of the transition pipe 1, a protruding portion 21 extending toward the transitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com