In-situ test sample platform

A sample platform and in-situ testing technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high price, in-situ high-temperature X-ray characterization limitations, single target, etc., and achieve accurate, controllable and fast heating and cooling rates Disassembly and assembly, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

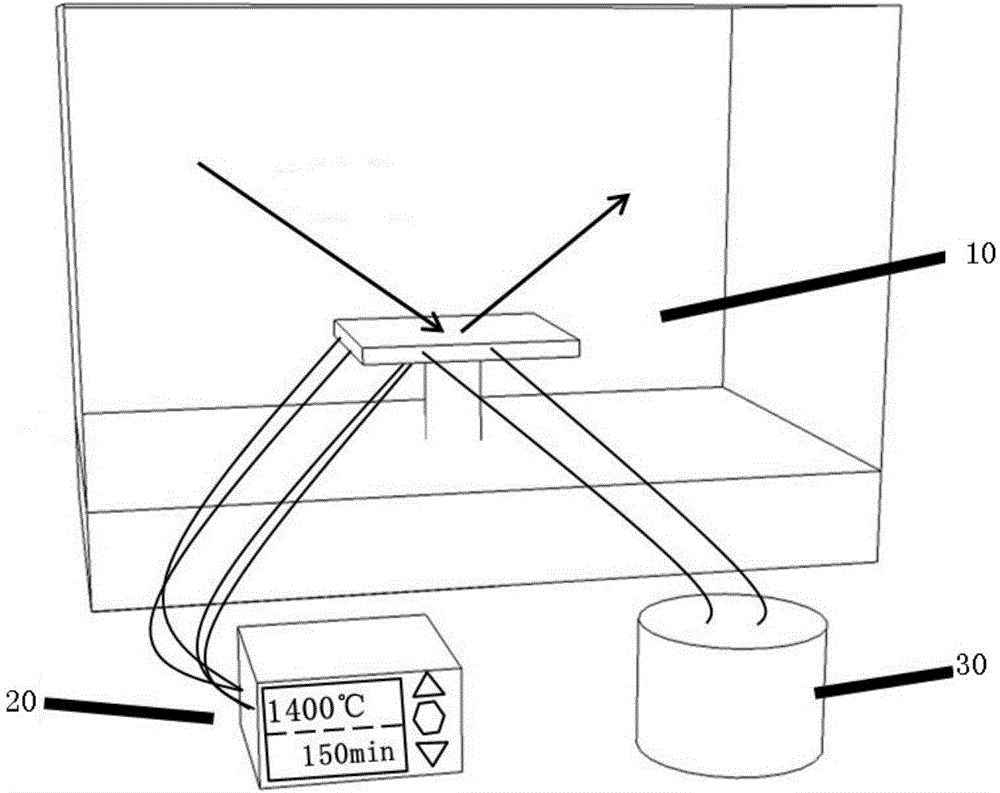

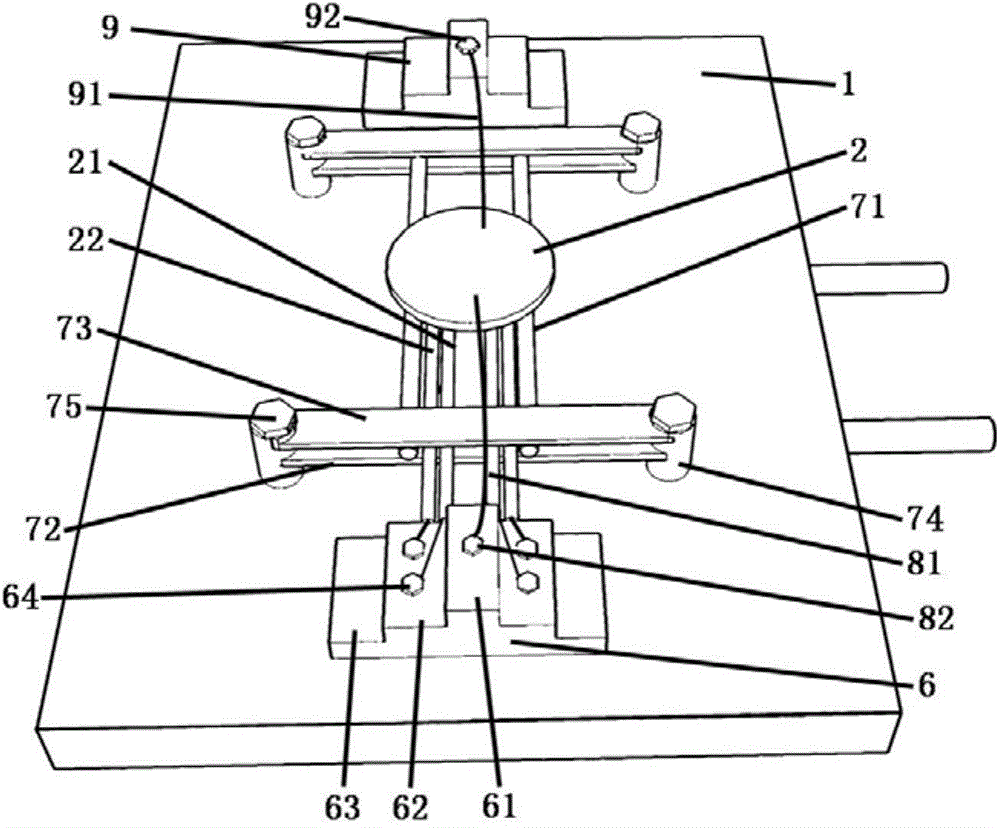

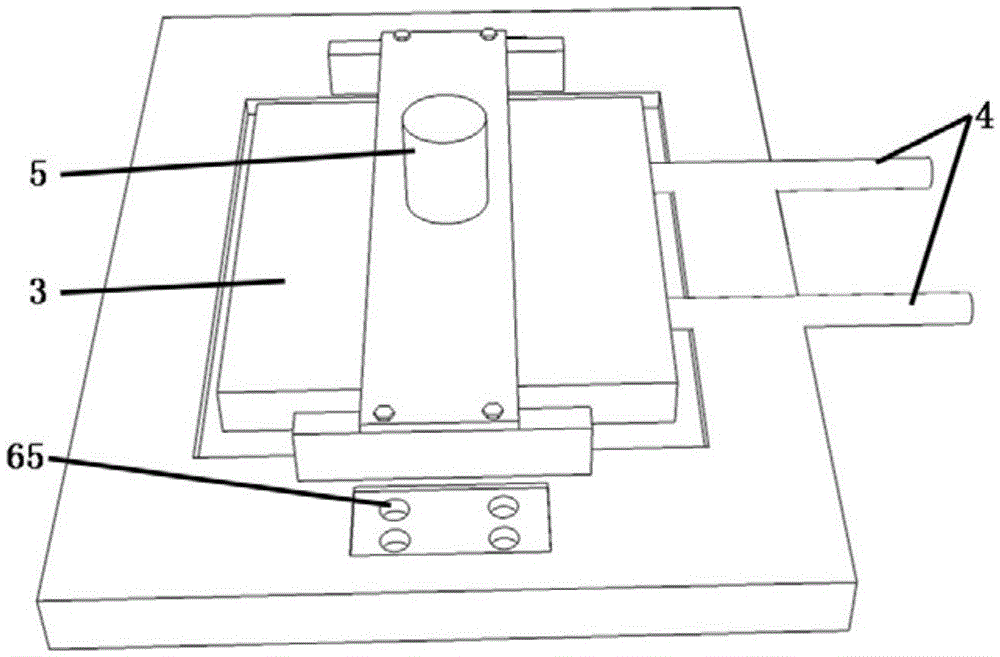

[0040] Such as Figure 1-3 As shown, the in-situ test sample platform of the present invention includes: a sample stage 1, a ceramic heating chip 2 with a heating wire (not shown) and a thermocouple (not shown) inside, used to support the ceramic heating chip 2 so that It is suspended above the sample stage 1 with a heating plate support frame, a sample stage base 5 installed on the lower surface of the sample stage 1, a temperature control system 20 for precisely controlling the temperature of the ceramic heating plate 2 on the sample stage 1, and a A circulating water cooling system 30 for cooling the sample stage 1 . Among them, such as figure 2 As shown, the heating wires inside the ceramic heating sheet 2 are connected through two heating wire wires 21 arranged on the lower surface of the ceramic heating sheet 2, and the internal thermocouples are con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com