Airfield runway ice and snow melting device

A technology for airport runways and airports, which is applied in the field of snow melting facilities and airport ice melting, can solve the problems of long time deicing and snow removal, complicated equipment structure, and flight safety impact, etc., and achieves convenient heat energy transmission and operation, simple equipment structure, Good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

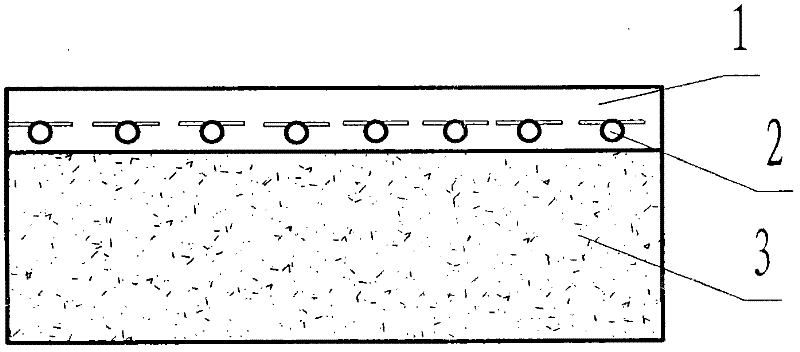

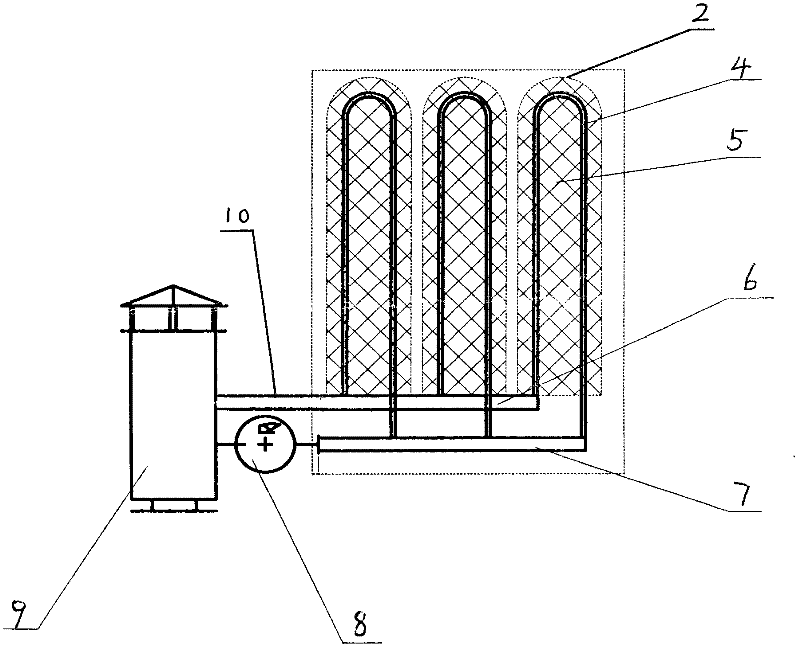

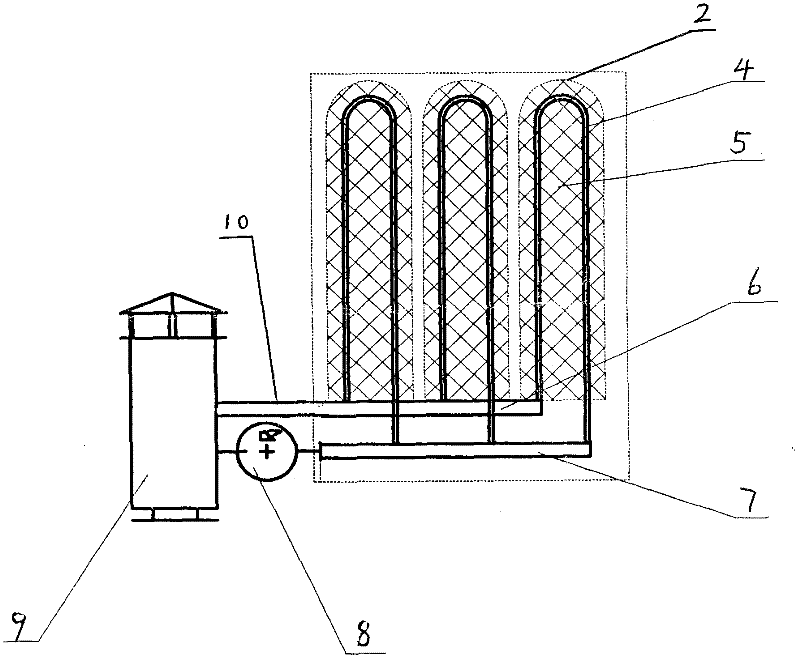

[0009] The airport runway ice melting and snow melting device of the present invention has an airport runway, and the airport runway comprises a runway base layer 3 and a runway surface layer 1, and a heat dissipation system is set between the runway base layer 3 and the runway surface layer 1, and the heat dissipation system Connected with the heat source system, the heat source system includes a circulation pump 8 and a heat source 9; the heat dissipation system is composed of a finned heat dissipation pipe 2, an oil inlet main pipe 6, an oil return main pipe 7 and a pipeline 10, and the oil return main pipe 7 of the heat dissipation system is composed of The outlet end is connected to the oil return port of the heat source 9, the body of the oil return main pipe 7 is respectively connected to the outlet ends of a plurality of finned cooling tubes 2, and the inlet end of the finned cooling tube 2 is connected to the oil inlet main pipe 6 The outlet ends are connected, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com