Straight-line rolling slipper block and method of manufacture

A manufacturing method and slider technology, applied in the direction of linear motion bearings, bearings, shafts and bearings, etc., can solve the problem that the actual accuracy and roughness of wire cutting can not meet the actual use requirements, affect the service life and stability, and friction Increased resistance and other issues, to achieve the effect of small friction coefficient, stable and precise upper and lower contact, and low heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

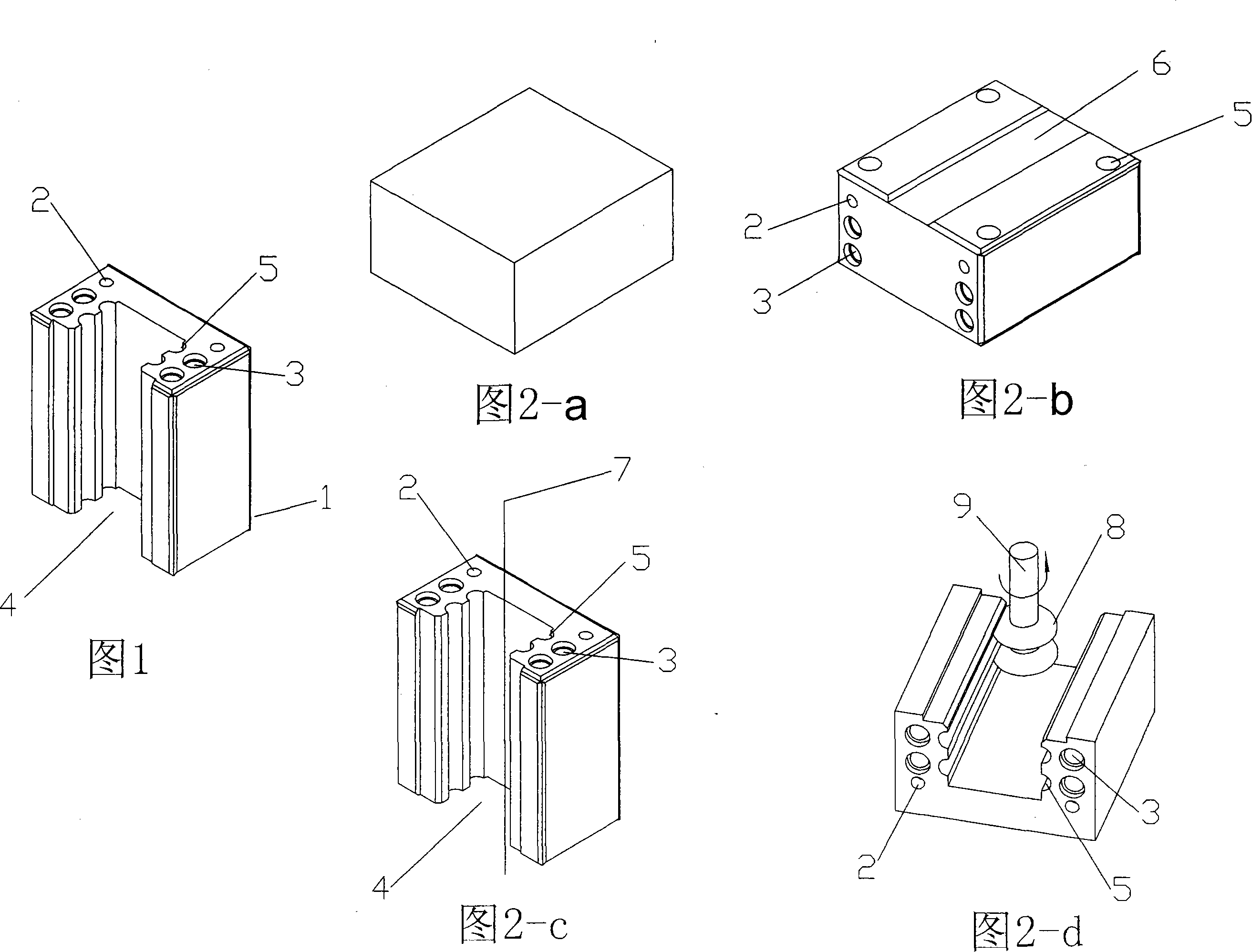

[0018] Metal slider body manufacturing method:

[0019] Metal slider body processing flow chart 2 shows that the slider body is made of high-quality bearing steel from Shanghai No. The best material for the body.

[0020] First, the bearing steel round bar is blanked on the cutting machine according to the tolerance requirements of the hot forging specification, and the dropped broken material is placed in the furnace to heat it to about 1000°C before hot forging, and each section of material is kept warm until the material is red. Forging. Forging and pressing use special molds to forge and press square green body blocks on 150T to 200T forging presses. The special mold material for forging is 5crMnMo, because of its good heat resistance and vibration resistance, long service life and durability.

[0021] Spheroidizing and annealing the forging and pressing blank. After putting the square blank in the annealing furnace, raise the furnace temperature to HRC750°C, keep it wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com