Oceanographic engineering flexible tube cable stretching bending combination experimental facility and experimental method

A technology of marine engineering and experimental devices, applied in the direction of measuring devices, strength characteristics, instruments, etc., to achieve superior flexibility, simple devices, and reduce the overall structure weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

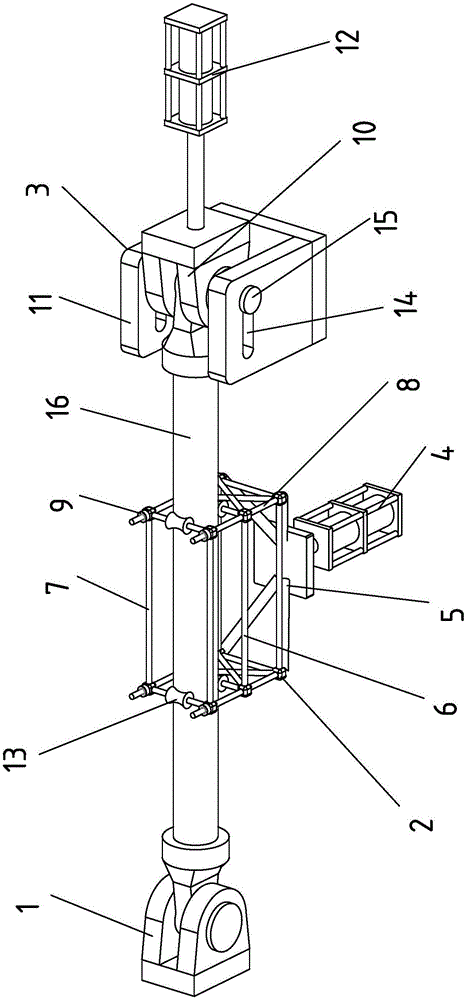

[0039] Such as Figure 1-Figure 4 As shown in Fig. 1, a combination experimental device for flexible umbilical cables in marine engineering, including a fixed rotary joint 1, a four-point bending truss device 2 and an axial tension device 3,

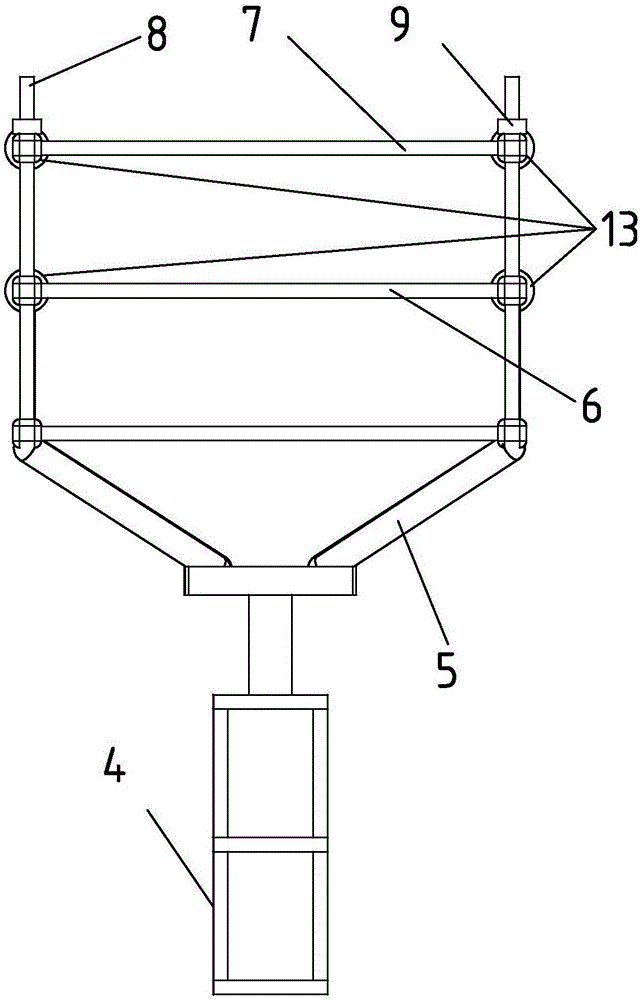

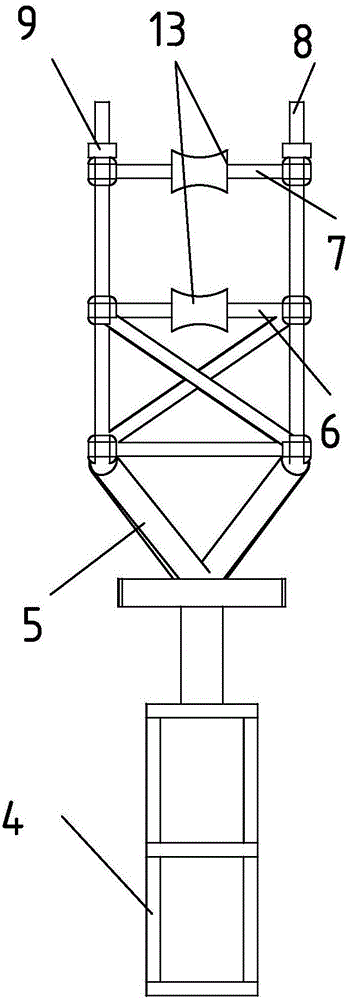

[0040] The four-point bending truss device 2 includes an actuator I4, a connecting frame 5, a quadrangular frame I6 and a quadrangular frame II7, the connecting frame 5 is in the shape of a quadrangular pyramid and the bottom surface of the connecting frame 5 is rectangular, and the connecting frame The orthographic projection of the vertex of 5 on the bottom surface of the connecting frame 5 coincides with the center of the bottom surface of the connecting frame 5, and the four vertices of the bottom surface of the connecting frame 5 are respectively provided with the axis of the connecting frame 5. Straight parallel threaded rods 8, the vertices of the quadrilateral frame I6 are fixedly connected to the connecting frame 5 through the thr...

Embodiment 2

[0048] A combined tensile-bending test method for flexible pipe cables in marine engineering has the following steps:

[0049] S1, design the experimental device as described in embodiment 1;

[0050] S2. Connect one end of the umbilical cable 16 to the fixed rotary joint 1 through the umbilical cable joint, and the other end of the umbilical cable 16 passes through the quadrilateral frame I6 and the quadrilateral frame II7, and connects to the said umbilical cable joint through the umbilical cable joint. The movable rotary joint 10 is connected;

[0051] S3. Adjust the position of the movable rotary joint 10 so that the axis of the umbilical cable 16 coincides with the connection line, adjust the four-point bending truss device 2 to be located in the middle section of the umbilical cable 16, and adjust the umbilical cable 16 according to the diameter of the umbilical cable 16. The position of the nut 9 ensures that the actuator I4 can be loaded stably;

[0052] S4. Evenly o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com