Improved method for testing tensile strength of material by bending test

A technique of tensile strength and bending test, which is applied in the direction of testing the strength of materials by applying a stable bending force, which can solve the difficulty of testing the tensile modulus of elasticity. quantity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 4

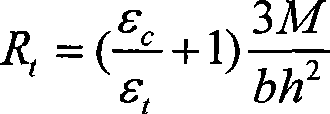

[0027] Embodiment 1 four-point bending test measures tensile strength

[0028] The material is processed into a rectangular parallelepiped sample, and the size of the rectangular parallelepiped meets the requirements of a slender beam, that is, the width of the sample is smaller than the height, and the ratio of the fulcrum span to the height is not less than 5. Pure bending loading is achieved using a four-point bending method. The two supporting points are arranged horizontally, and they are equidistant from the geometric center of the beam. The two loading points are also arranged horizontally, and the distance from them to the geometric center of the beam is equal, then the bending moment on any cross-section of the sample between the two loading points is a constant value, that is, the beam between the two loading points is a purely curved beam. Measure the strain value of the upper and lower surfaces of the pure bending section during the loading process by the resista...

Embodiment 2 3

[0029] Embodiment 2 three-point bending test measures tensile strength

[0030] The material is processed into a rectangular parallelepiped sample, and the size of the rectangular parallelepiped meets the requirements of a slender beam, that is, the width of the sample is smaller than the height, and the ratio of the fulcrum span to the height is not less than 5. The three-point bending method is used to achieve transverse bending loading. Assume that the two fulcrums are arranged horizontally, and their distances from the geometric center of the beam are equal. The geometric center of the imposed load spans the beam and is perpendicular to the horizontal axis of the beam. Choose a cross-section in the bending section of the beam, arrange measuring points on the upper and lower edges of the cross-section, and test the strain in the axial direction of the beam. Load the sample, the load gradually increases from 0 to the sample failure, record the load P, and the strain value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com