Accelerating and loading device and method for indoor test of road surface materials

A technology of accelerated loading and indoor testing, applied in the direction of using optical devices, using mechanical devices, analyzing materials, etc., can solve the problems of high test cost, low anti-skid performance, and large impact, and achieves strong objectivity, simple production, Applicable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention have been described in detail above in conjunction with the accompanying drawings.

[0036] The size of the asphalt mixture test piece of the present invention is Φ150mm in diameter and 150-200mm in height.

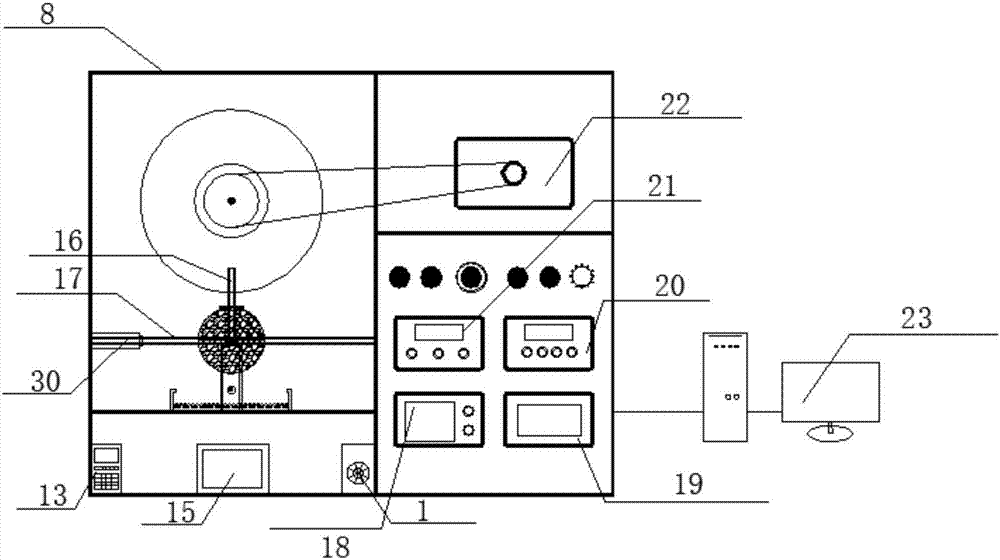

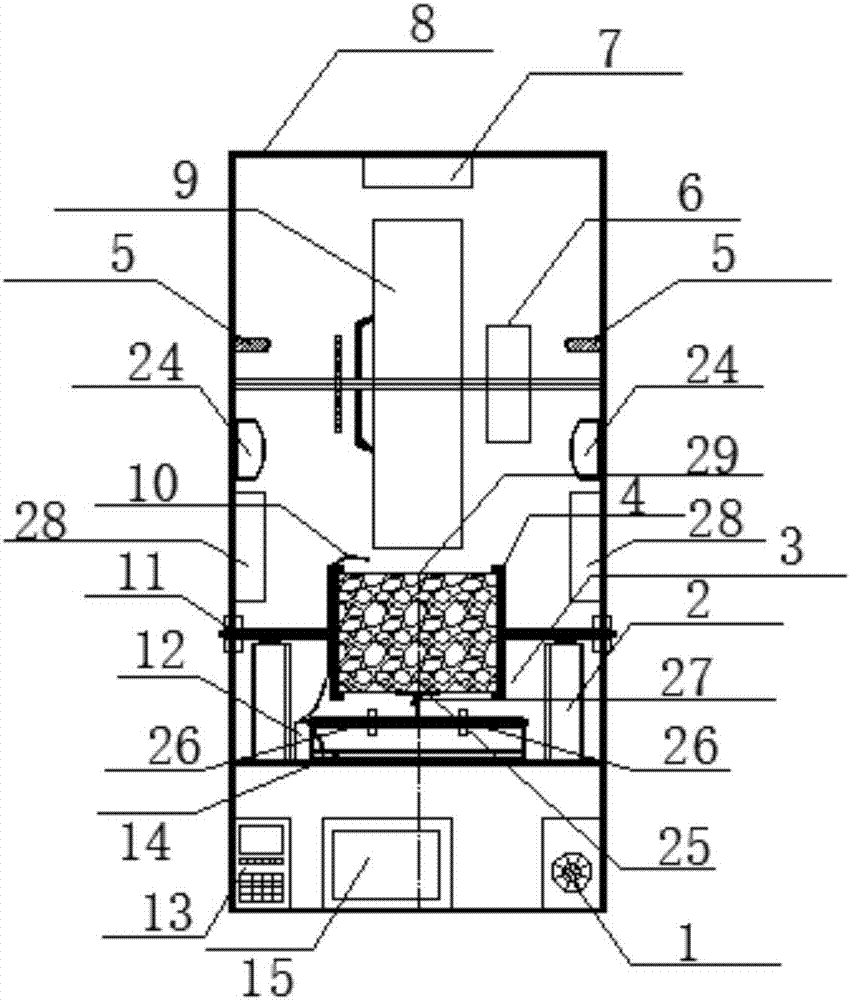

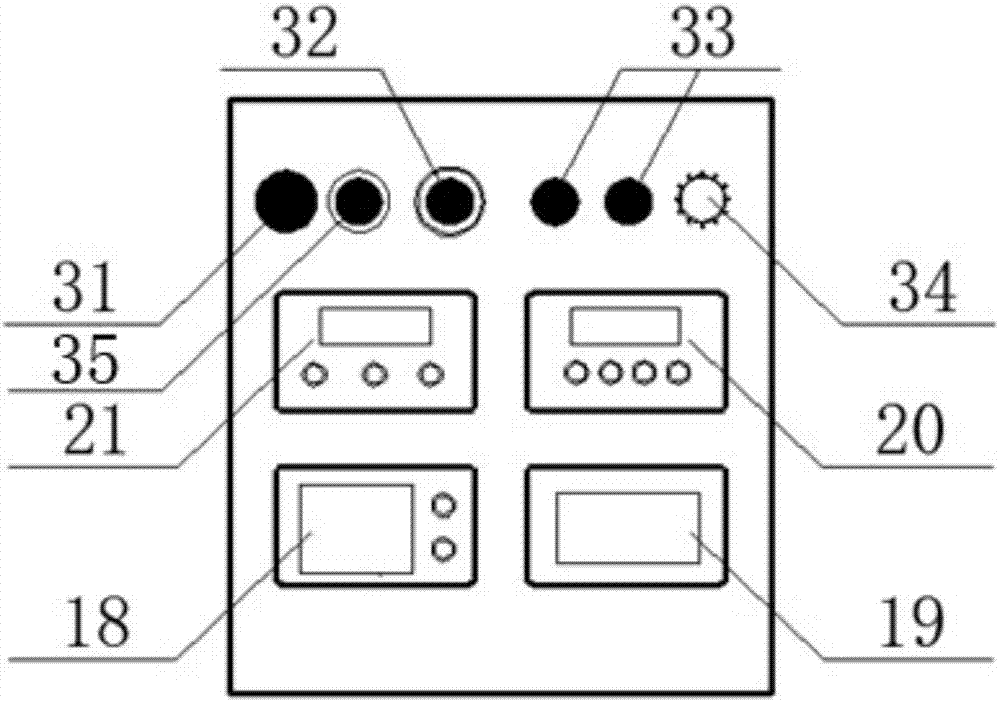

[0037] Such as figure 1 and figure 2 As shown, an accelerated loading device for indoor testing of pavement materials, including a constant temperature box 8, an operating table, a tire 9, a motor 22, a transmission belt, a tachometer 6, a water pump 12, a water tank 14, a water spray head 10, and a temperature sensor 3 , 5. Circulating air inlet 7, circulating air outlet 28, noise detector 13, hydraulic device 2, specimen fastening module 4, tension and pressure sensor 25, self-elevating test wheel 27, support wheel 26, laser structure instrument 30 . Computer 23, the thermostat box 8 is located on the left side of the test device, the operating table is located on the lower right side of the outer wall of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com