Vertical elastic tension and compression support

An elastic and vertical technology, applied in the direction of bridge parts, bridge materials, bridges, etc., can solve problems such as the inability to meet the construction requirements of large-scale suspension cable bridges, and the inability of bearings to bear pressure and horizontal displacement at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

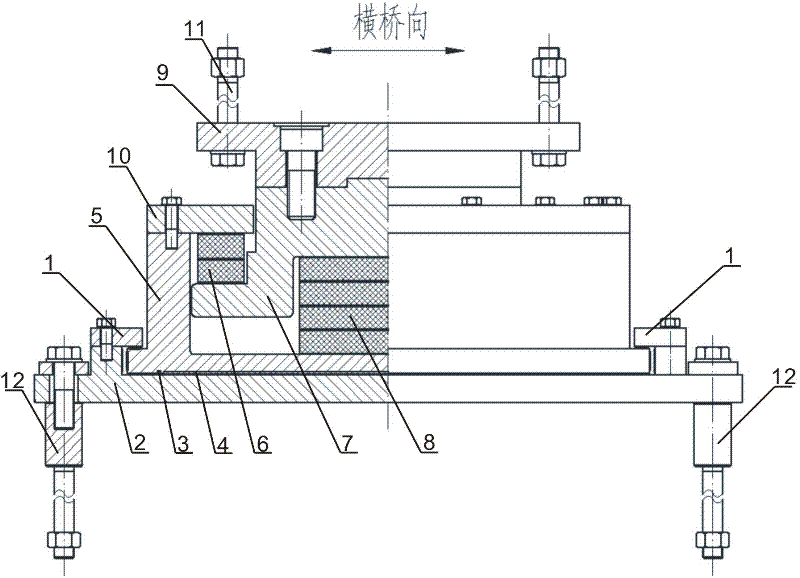

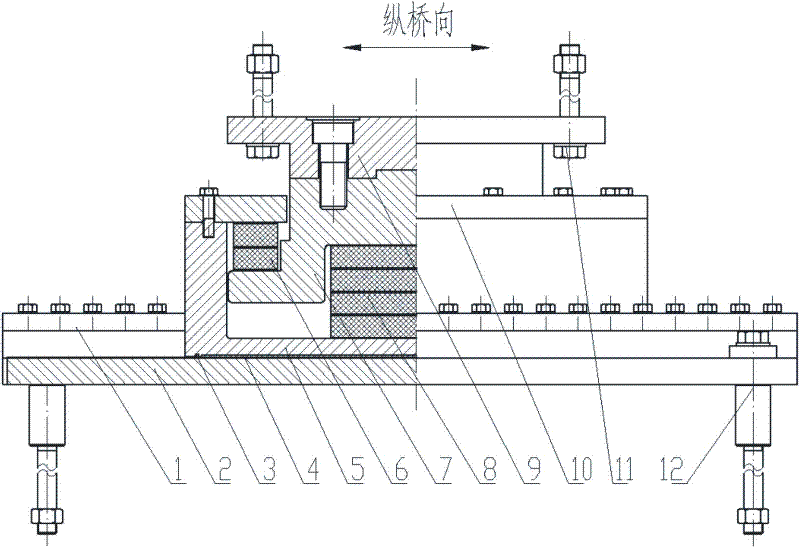

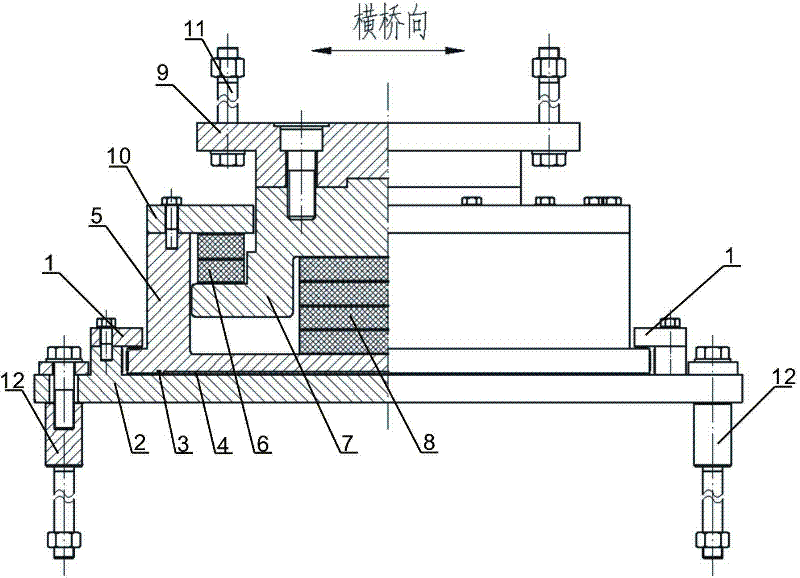

[0027] Such as figure 1 , 2 Shown: vertical elastic tension-compression support, which includes pressure plate 1, slide plate 2, elastic sealing ring 3, wear-resistant plate 4, steel basin 5, tension damper 6, middle steel lining plate 7, pressure damper 8 , Top plate 9, pressure ring 10, upper anchoring device 11, lower anchoring device 12. An upper anchoring device 11 is fixed on each corner of the upper end surface of the top plate 9 , and a lower anchoring device 12 is fixed on each corner of the bottom surface of the slide plate 2 , a steel basin 5 is arranged above the slide plate 2 , and a pressure ring 10 is fixed on the top of the steel basin 5 . The pressure plate 1 is fixed on both sides of the slide plate 2, a wear plate 4 is provided between the slide plate 2 and the steel basin 5, and an elastic sealing ring 3 is provided around the wear plate 4; a pressure damper 8 is provided in the center of the steel basin 5 , the top of the pressure damper 8 is fixed with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com