Method for measuring static elasticity modulus of porous metal material

A technology of porous metal and elastic modulus, applied in the direction of applying stable tension/pressure to test material strength, mechanical solid deformation measurement, etc., can solve problems such as expensive equipment, poor synchronization and coordination of elastic deformation, and difficulty in pasting strain gauges , to achieve the effect of simple operation, accurate measurement results and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] 1. Experimental equipment

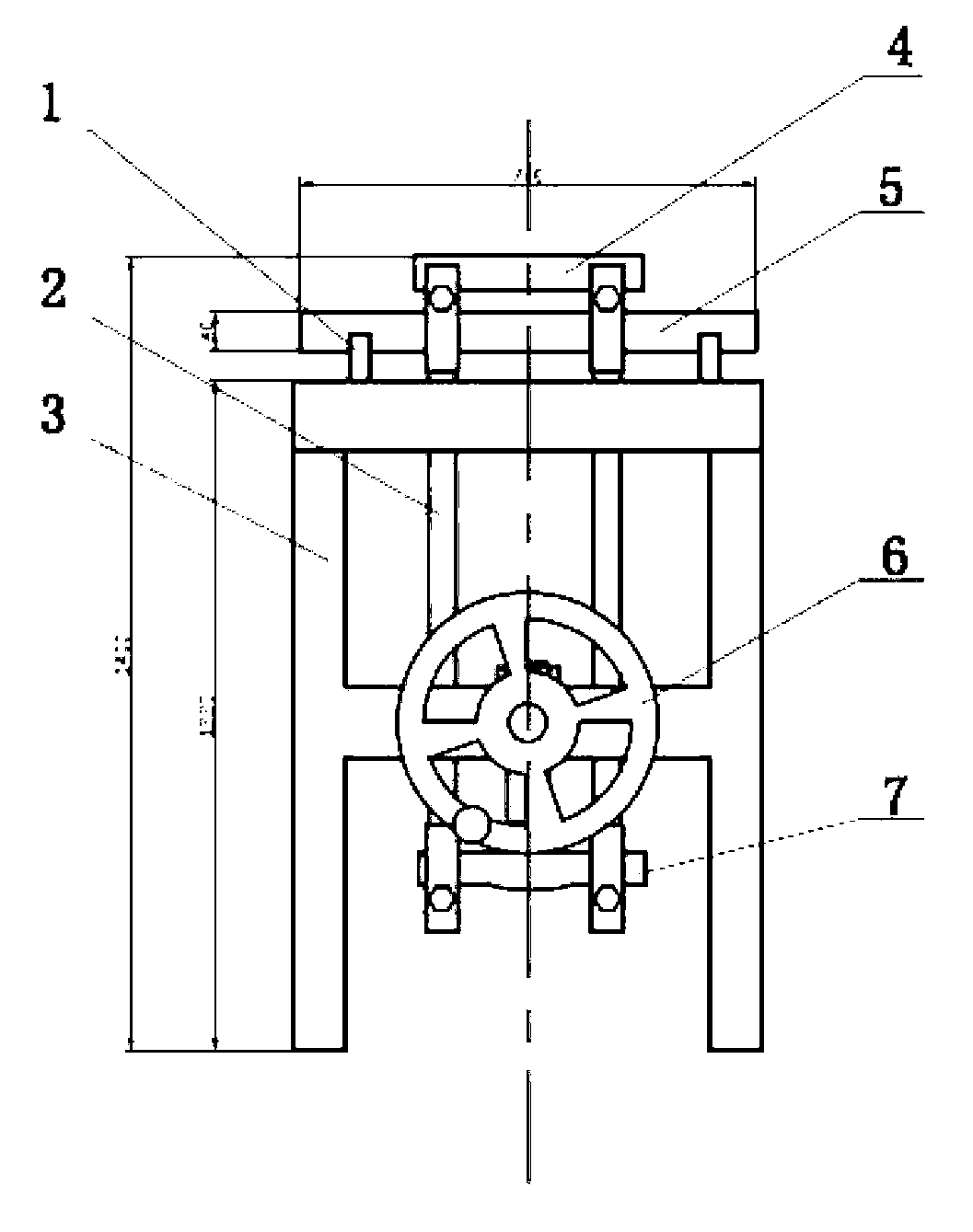

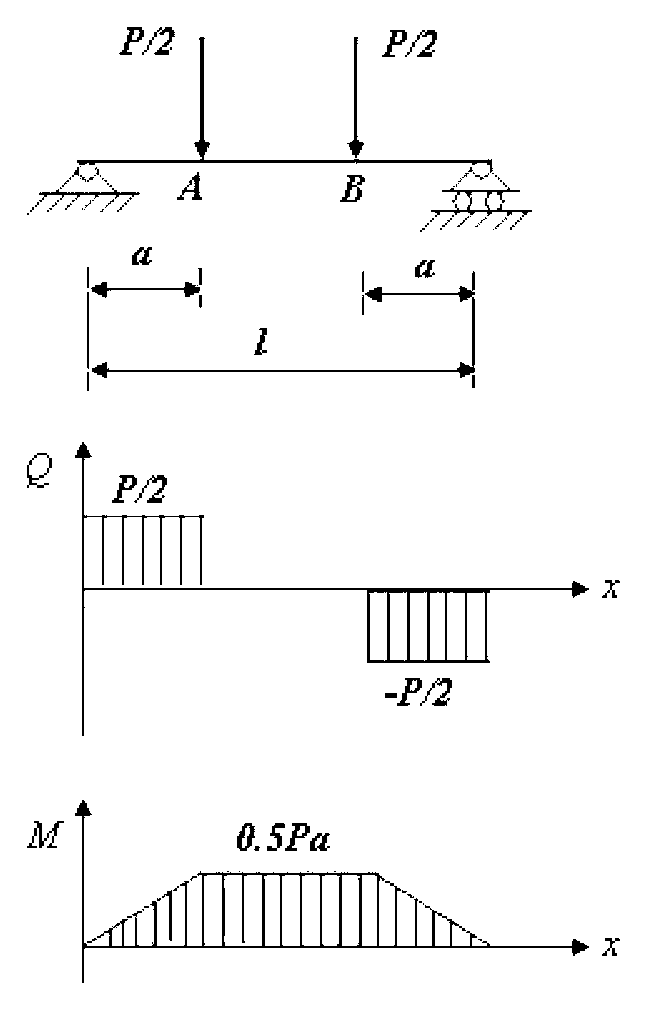

[0028] a) Simply supported beam pure bending (four-point bending) experimental device. The main body of the device is CLDT-C material mechanics multifunctional electric test bench, and its structure diagram is as follows figure 1 As shown, it mainly includes a support block 1 , a loading link 2 , a base 3 , an upper loading auxiliary rod 4 , a material sample to be tested 5 , a loading handle 6 and a lower loading auxiliary rod 7 . Pure bending experiment is one of the most basic and common material mechanics (teaching) experiments. The experimental device is very simple, easy to operate, and the price is low. Most of the material mechanics laboratories of universities, scientific research institutes and related industry units There is the experimental equipment.

[0029] b) XL2188 force and strain comprehensive parameter tester.

[0030] c) Dial indicator or dial indicator.

[0031] d) Weights and hooks.

[0032] 2. Material to be tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com