Pure bending age forming die

A technology of aging forming and pure bending, which is applied in the field of mechanical processing and can solve the problems that the pure bending loading of test pieces cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

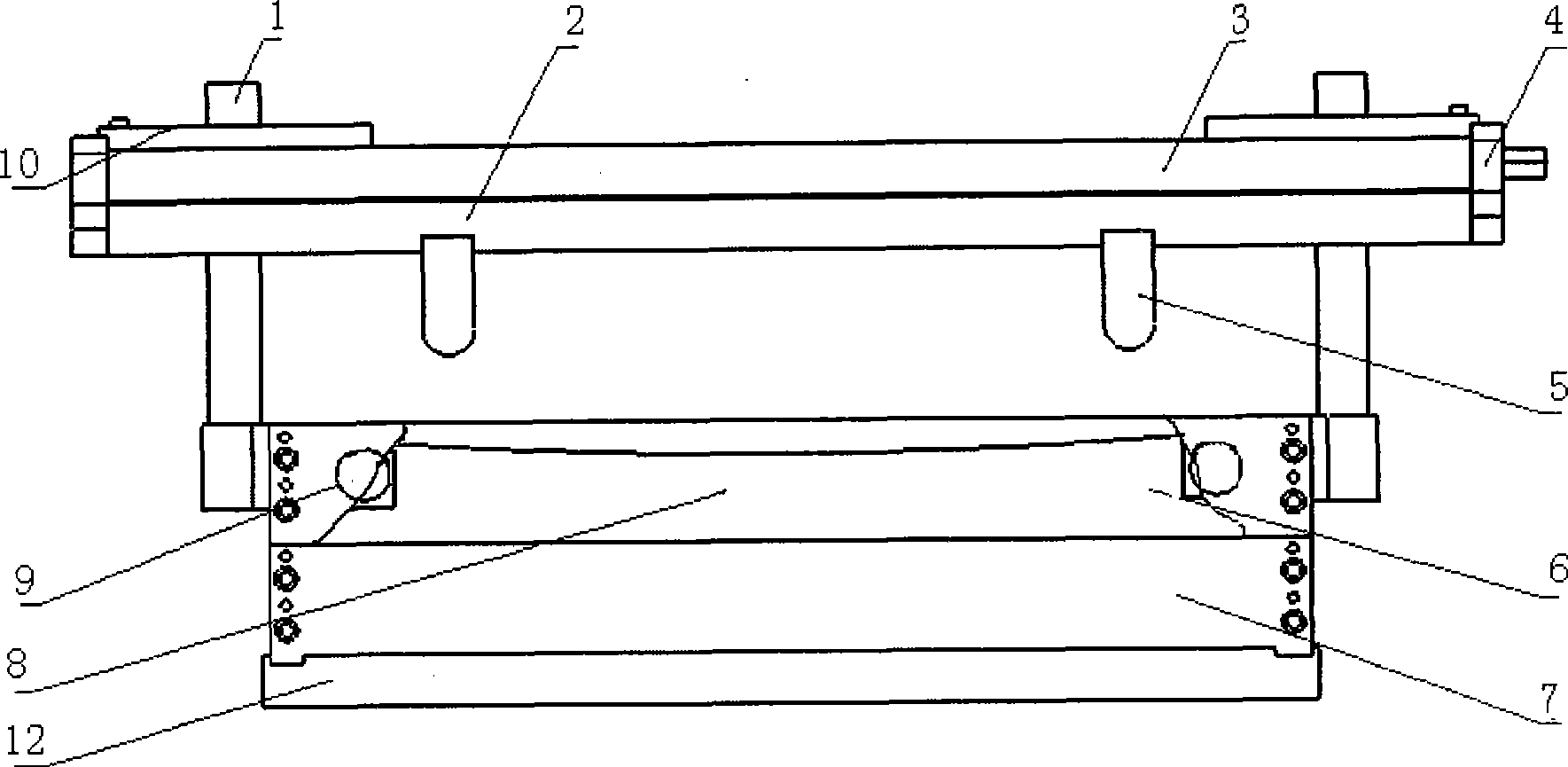

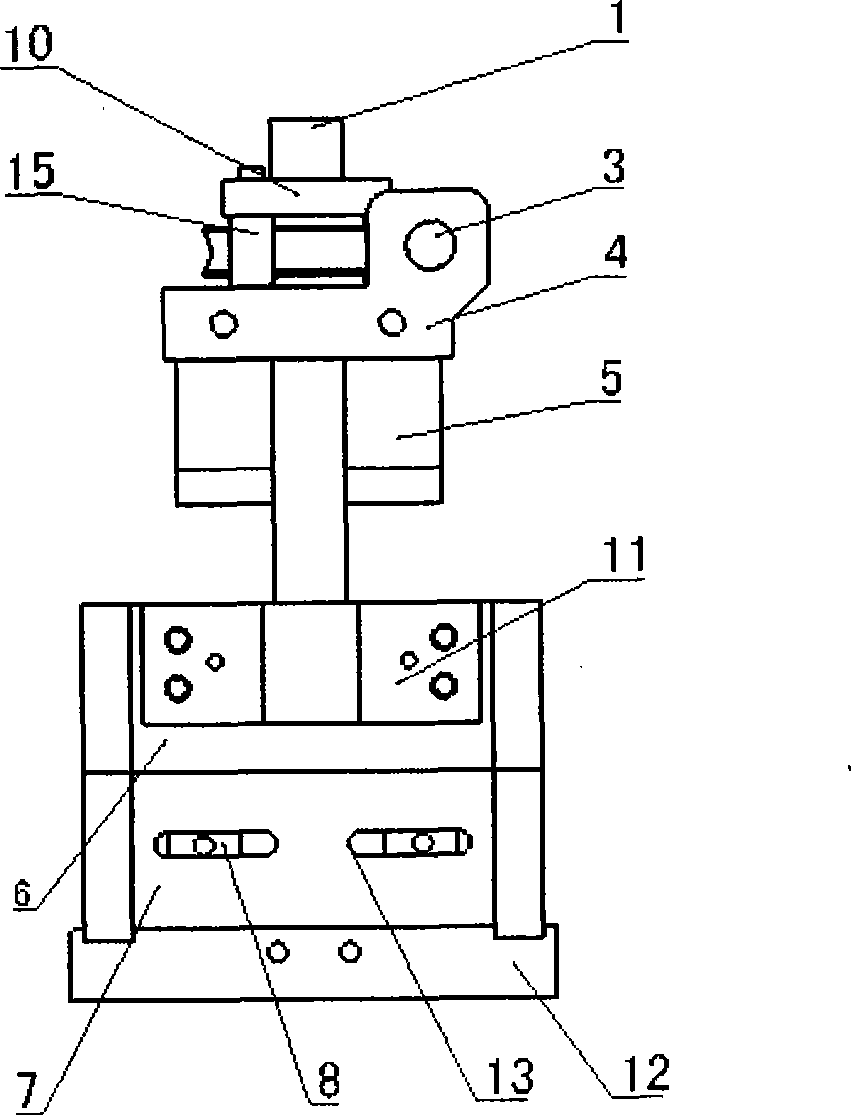

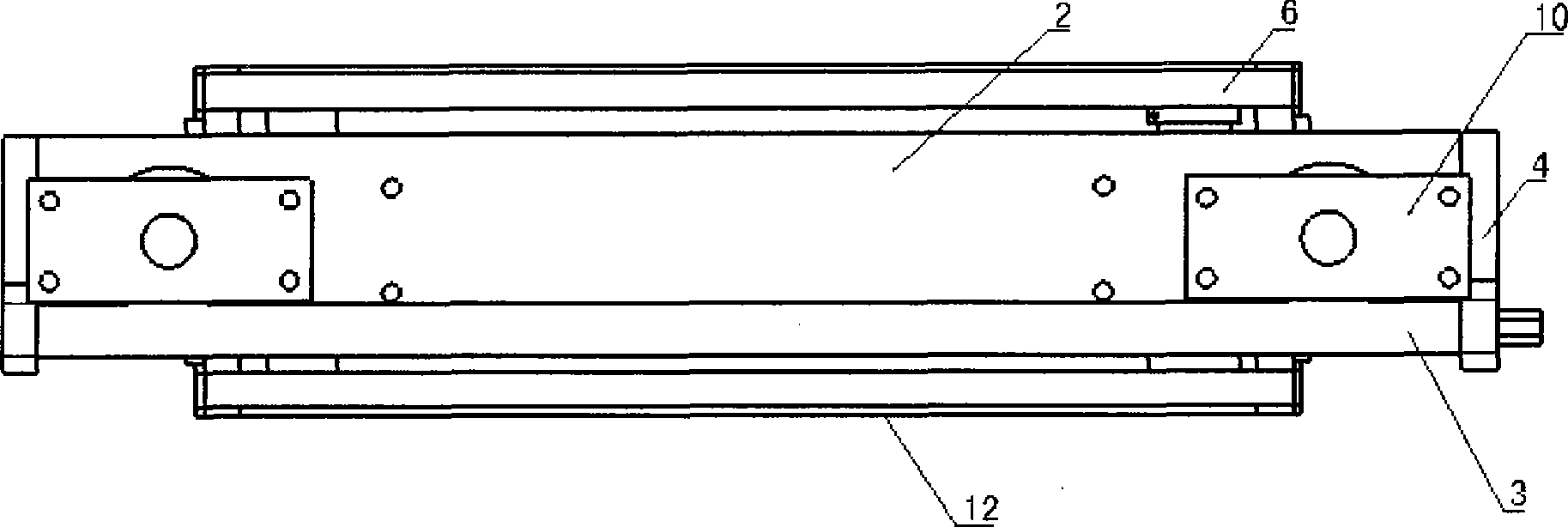

[0018] This embodiment is used for (500 × 50 × 5) mm thick plate pure bending aging forming die (attached figure 1 ), the present embodiment is a combination structure of four-point bending and frame plate structure, including base plate 12, pressure block 5, upper frame plate 6, lower frame plate 7, shape plate 8, worm screw 3, lead screw 1, pressure plate 2 And worm gear baffle 10, wherein:

[0019] One piece of base plate 12 is rectangular, and the periphery around the upper surface of this plate is provided with through groove 16. The lower frame plate 7 has four pieces, all of which are rectangular strips, whose thickness is the same as the width of the bottom plate through groove 16, embedded in the bottom plate through groove 16, and fixed by bolt holes positioned in the bottom plate through groove; The square surrounded by the lower frame plates 7 constitutes the mold cavity; the four lower frame plates 7 are fixedly connected to each other by bolts at four corners. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com