Metal pipe pure bending deformation test device and test method thereof

A deformation test, pure bending technology, applied in measuring devices, using stable bending force to test the strength of materials, instruments, etc., can solve the problems of structural failure, inability to accurately reflect the overall bending performance of the pipeline, etc., to achieve small accidental errors, avoidance of Local failure phenomenon, the effect of avoiding accidental errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

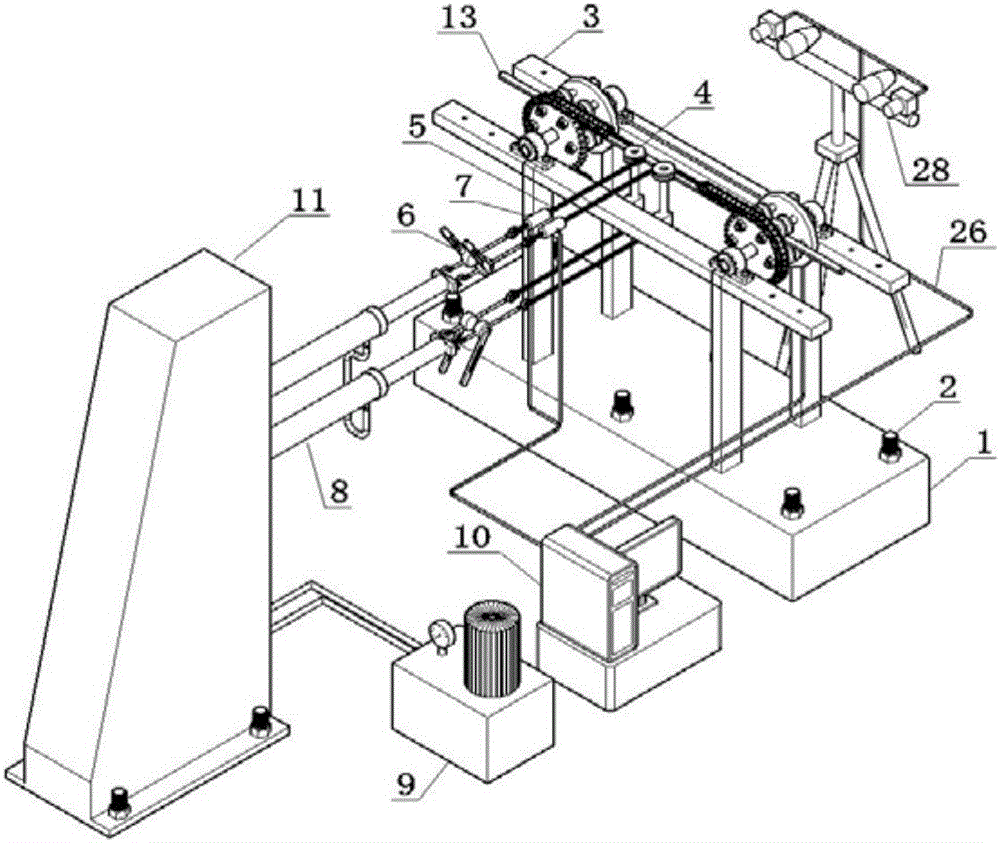

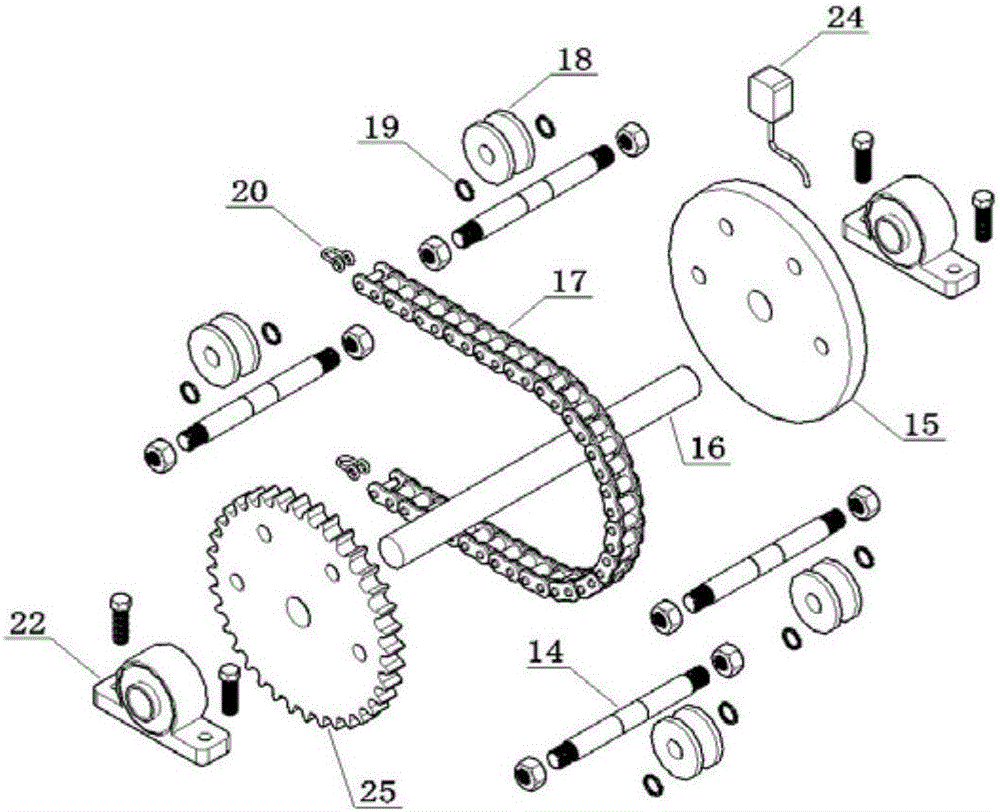

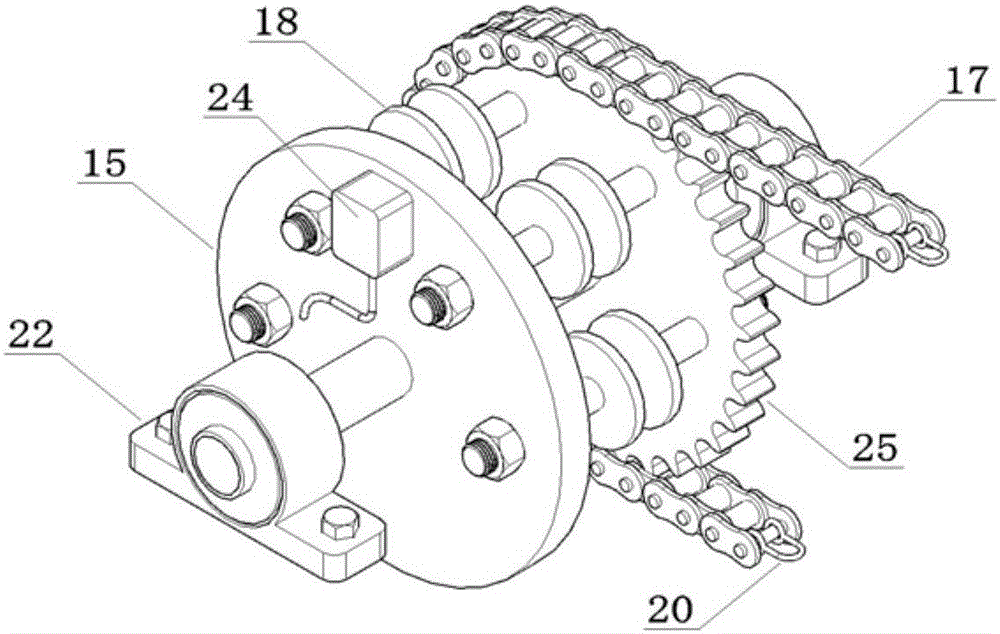

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0059] like Figures 1 to 3 As shown, the metal pipe pure bending deformation test device of the present invention includes seven parts: a reaction force frame 11, a frame 3, a hydraulic double-acting jack 8, a loading assembly, a hydraulic station 9, a data acquisition assembly, and a computer terminal 10. Wherein, the above-mentioned reaction force frame is a pier column, and the above-mentioned frame is of a double-bar structure, including four legs and two beams, wherein the beam is a strip plate;

[0060] The reaction frame is separated from the frame, arranged one on the left and one on the right;

[0061] The above-mentioned hydraulic double-acting jack includes two cylinders, and the bases of the two cylinders are respectively fixed on the above-mentioned reaction frame;

[0062] The above-mentioned loading assembly includes two sets of drive wheel assembli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com