Fine adjustment device for die entering angle of wet drawing steel wire

A technology of angle fine-tuning and steel wire, which is applied in the direction of wire drawing dies, etc., can solve the problems of abnormal quality of finished steel wire warping, uneven stress distribution, affecting the quality of wet-drawn finished products, and the use of equipment, so as to eliminate uneven force and improve Effect of Finished Wire Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

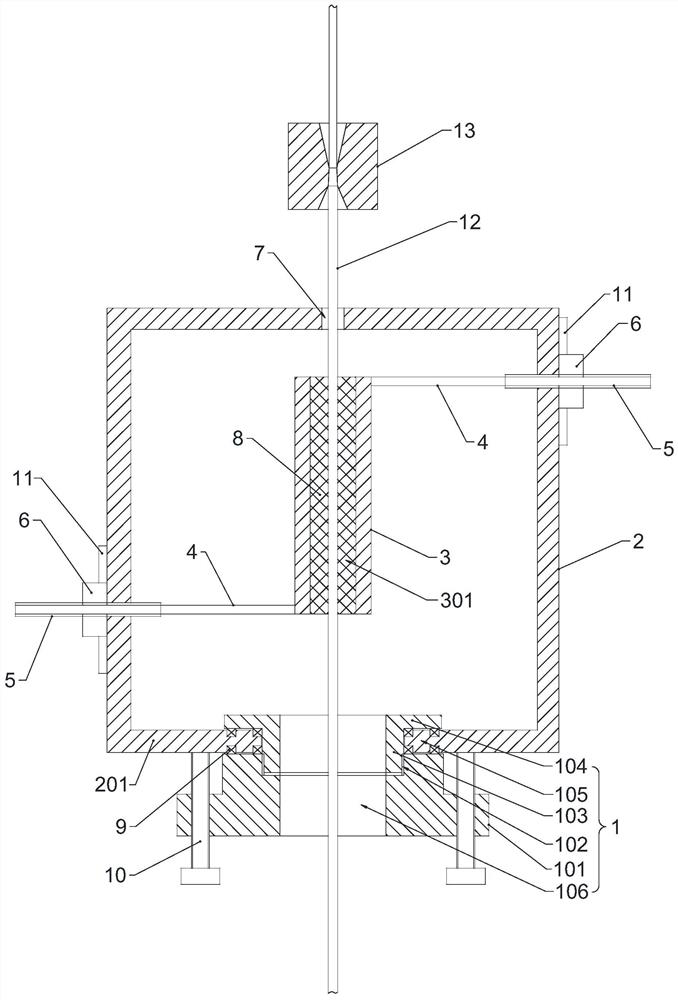

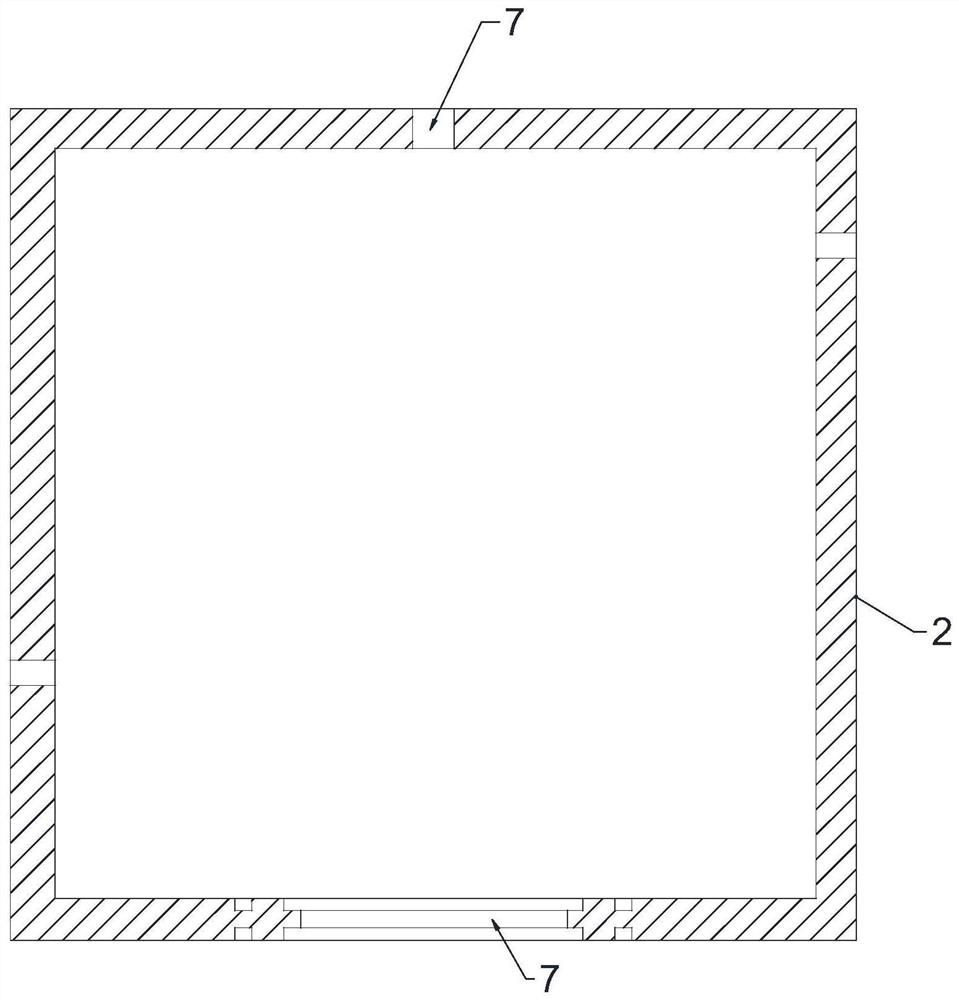

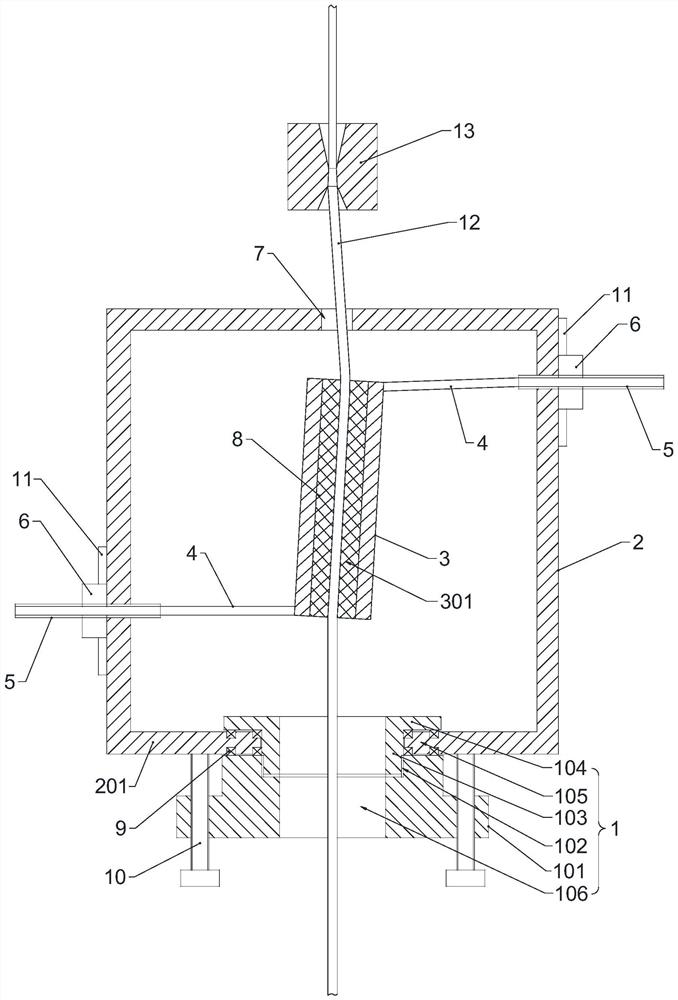

[0016] like Figure 1~Figure 3 As shown in the figure, a fine-tuning device for the feeding angle of wet-drawn steel wire includes a swivel base 1 fixedly connected to the frame of the wet-drawing machine, a swivel box 2 rotatably connected to the swivel base 1, and a swivel box suspended on the swivel box 2. The inner straight tubular swinging member 3, the elastic support rods 4 connected to the axial ends of the swinging member 3 and extending radially along the swinging member 3, are connected to the free ends of each supporting rod 4 in one-to-one correspondence and along the axis of the supporting rod 4. The outwardly extending adjusting screw rod 5 and the adjusting nut 6 threadedly connected with the adjusting screw rod 5 one by one, the two support rods 4 are respectively arranged on both sides of the swing member 3 and extend in oppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com