Novel scanning probe microscope detecting method and system

A scanning probe and detection system technology, applied in the field of microscopy, can solve the problems of high cost, complex structure, unfavorable system rapid scanning imaging, etc., and achieve the effect of simple structure, guaranteed response frequency, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

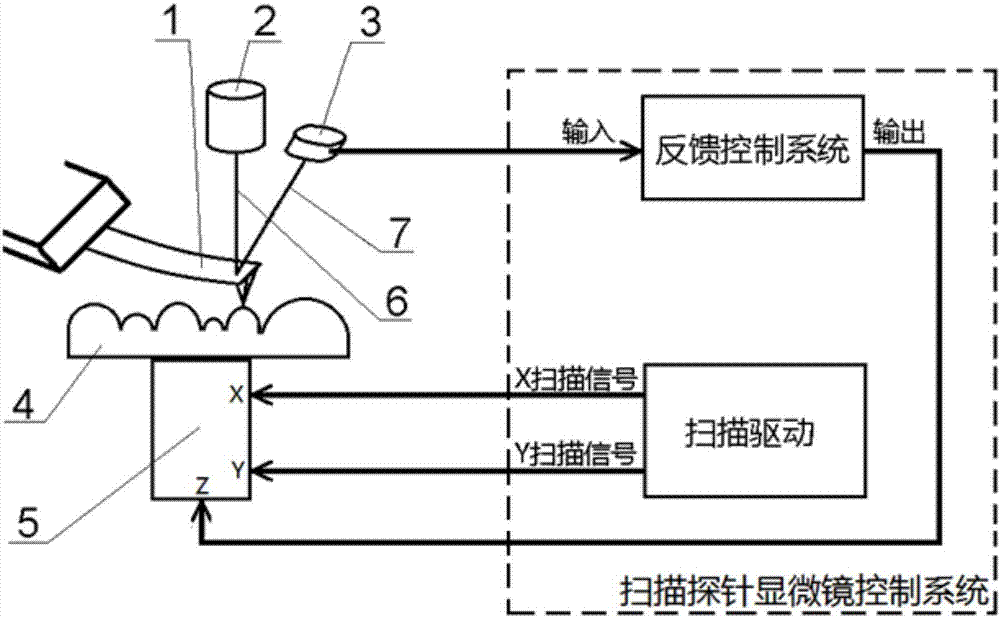

[0097] Aiming at the problem that new optical elements or optical systems need to be introduced in the prior art and the actual load of the scanning drive device will be increased, the present invention proposes a novel scanning probe microscope detection method and system.

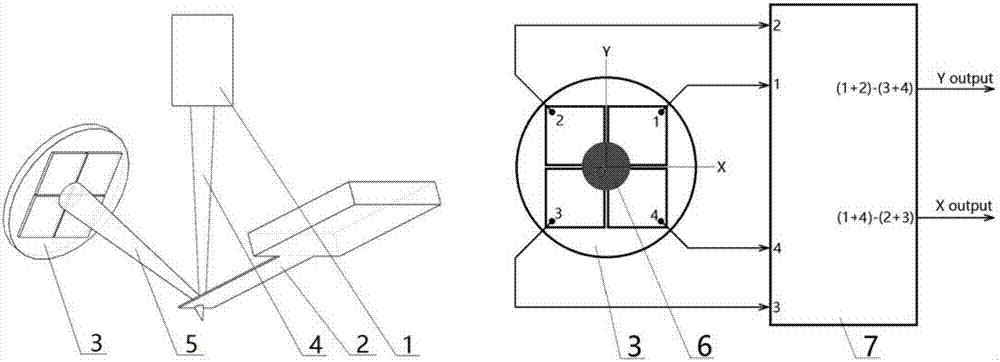

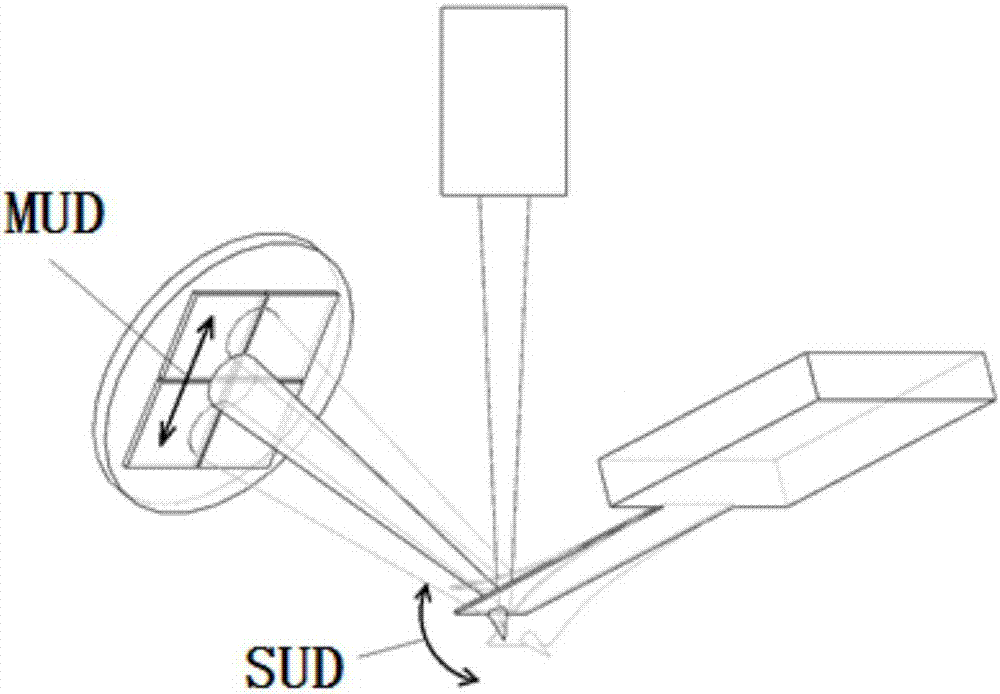

[0098] Such as Figure 12 As shown, this embodiment proposes a scanning probe microscope implementation of a new probe movement mode, without adding any optical system or components, by changing the spatial position of the laser and the four-quadrant receiver, the central axis of the incident laser beam 1. The plane where the central axis of the reflected laser beam is located is perpendicular to the extension axis of the cantilever beam of the micro-cantilever probe, so as to achieve the purpose of completely decoupling the detection signals of the two motion modes of the probe bending and the probe lifting. Figure 12 (a), (b), (c) and (d) are three-dimensional perspective view, top view, front view and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com