Pipe bender precision control method

A technology of precision control and pipe bending machine, which is applied in the field of pipe bending machine control, can solve the problems of uncontrollable bending precision of pipe bending machine, many times of manual bending, and high scrap rate, so as to improve competitiveness, reduce labor intensity, and reduce scrap products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

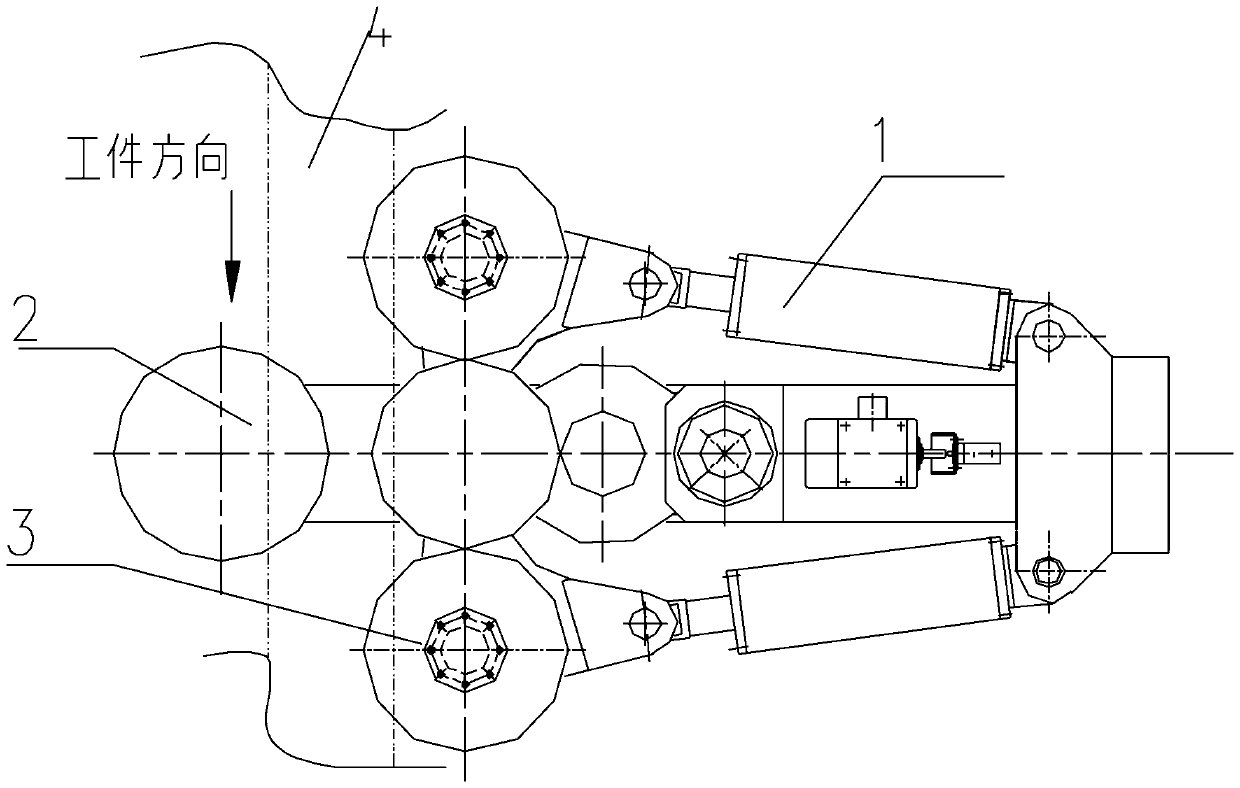

[0039] Bending the straight pipe of stainless steel seamless steel pipe into a U-shaped pipe, taking the synchronous and symmetrical movement of the rollers on both sides as an example, the main control process is as follows:

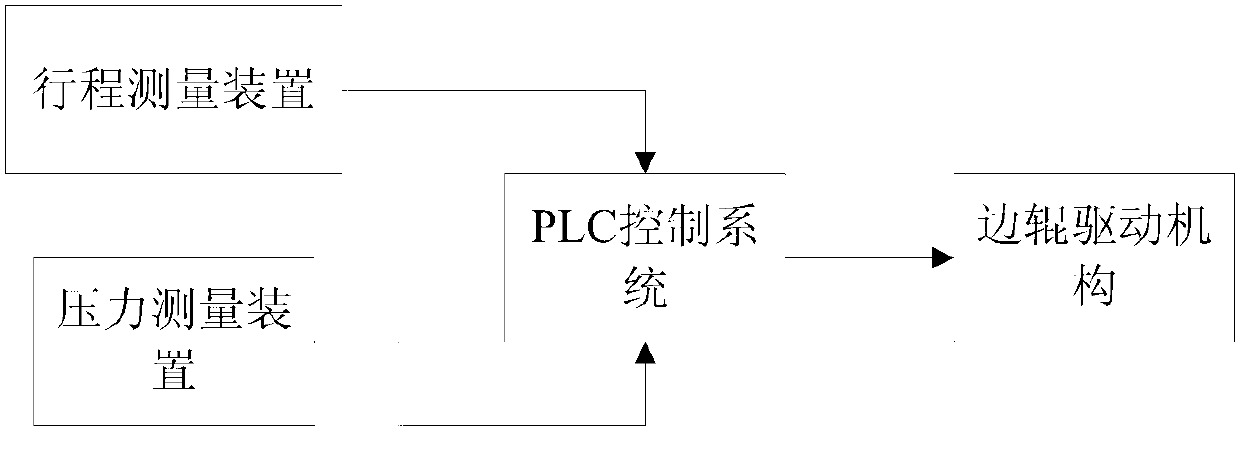

[0040] (1) Input the pipe size parameters and steel material type, the PLC control system collects the material parameters of the corresponding steel grades stored in the system according to the input results, calculates and displays the pipe bending moment M of different pipe materials at the corresponding curvature radius by the moment formula; In this embodiment, the pipe material is a stainless steel seamless steel pipe material;

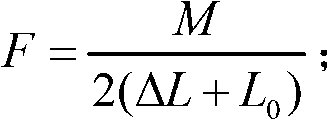

[0041] bending moment The formula takes an equal sign, where,

[0042] D - the outer diameter of the pipe;

[0043] ρ—the radius of curvature of the curved neutral layer;

[0044] σ b - the tensile strength of the material;

[0045] W——flexural section modulus;

[0046] Input pipe size parameters: pipe outer diamet...

Embodiment 2

[0058] Bending the straight pipe of stainless steel seamless steel pipe into a U-shaped pipe, taking the asymmetrical movement of the rollers on both sides as an example, the main control process is as follows:

[0059] (1) Input pipe size parameters: pipe outer diameter D is 10-16mm, wall thickness is 0.5-1.5mm;

[0060] Collect and store the material parameters of the steel grades: the radius of curvature ρ of the curved neutral layer is 32mm; the tensile strength of the stainless steel seamless steel pipe material σ b is 381~600Mpa, in this embodiment σ b The value is 600Mpa;

[0061] Calculate the bending moment M=443N.m;

[0062] (2) The detected distance L between each side roller and the main roller at the beginning 0 is 300mm; at this time, because there is no bending pressure, the hydraulic thrust F driven by the side roller is 0;

[0063] (3) The PLC system is based on the constraint relationship between the bending moment M, the bending pressure F and the moving...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com