Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

A technology of static pressure turntable and experimental device, which is applied in the direction of measuring devices, instruments, and mechanical parts testing, etc., and can solve problems such as the decline of oil film bearing capacity, obvious circumferential vibration of turntable, oil film oscillation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

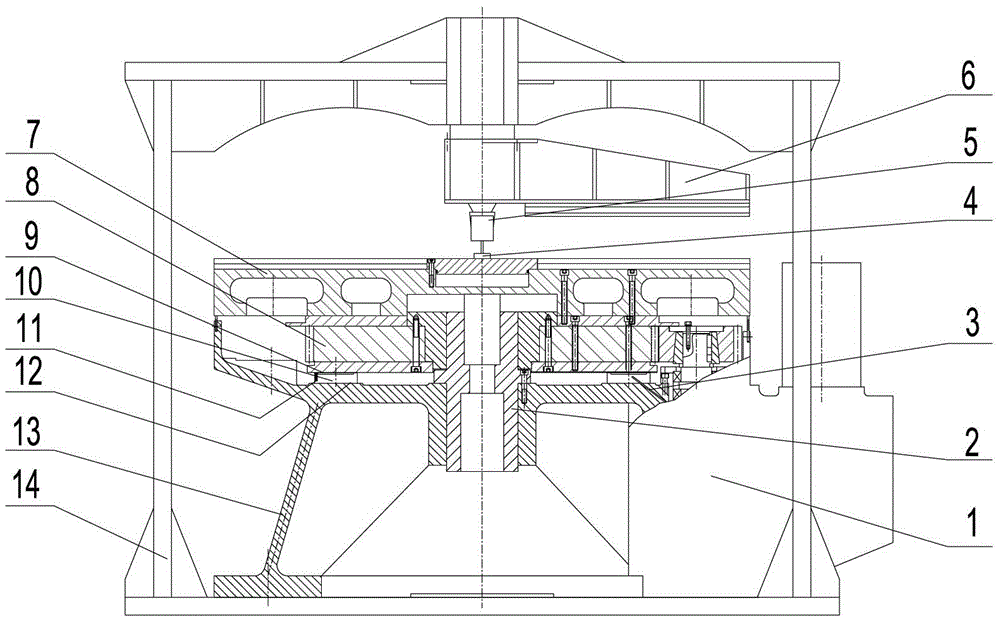

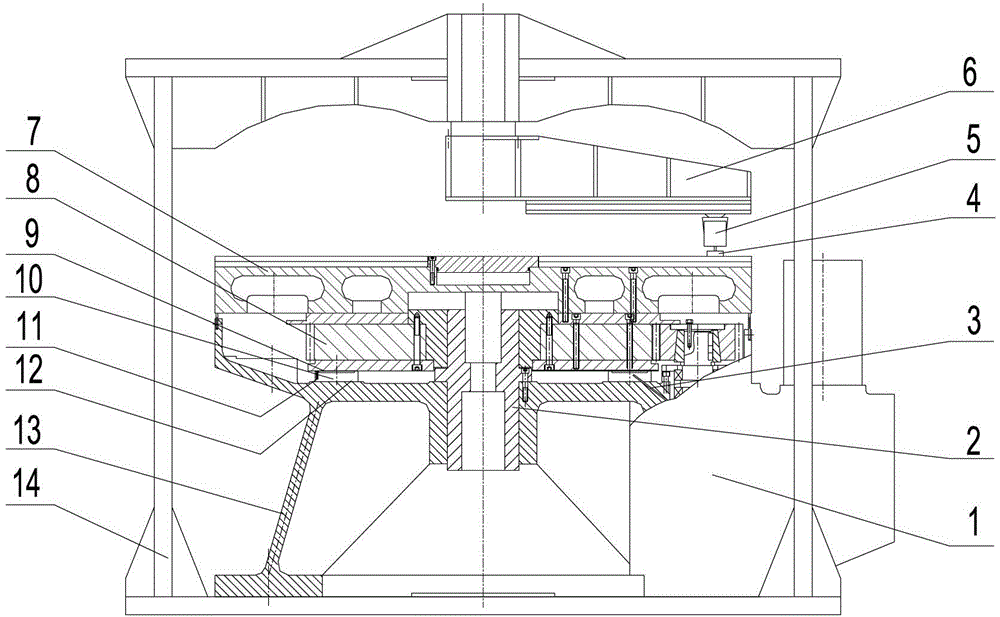

[0054] A preferred embodiment of the quantitative static pressure turntable dynamic and static characteristics experimental device of the present invention will be described in detail below in conjunction with the working principle and the structural drawings.

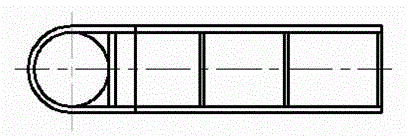

[0055] The structure of this embodiment is as Figure 1-3 As shown, the middle of the beam of the loading bracket 14 is connected to the loading arm 6 through a shaft. The structure of the loading bracket 14 is shown in Figure 6(a) and (b), which is composed of two gate-shaped frames intersecting to form a stable frame structure; one end of the loading arm 6 passes through the shaft and the X-shaped beam of the loading bracket 14 The middle connection, the structure of the loading arm 6 is shown in Figure 5 (a), (b).

[0056] The loading device 5 is installed under the loading arm 6, and can move along the loading arm 6 through two roller bearings to realize central loading and partial loading. The loading device 5 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com