Oil unloading device vehicle for railway oil tank and oil transportation method thereof

A technology of railways and oil tanks, which is applied in the field of oil unloading vehicles and their oil delivery, which can solve the problems of slow delivery and delivery of oil and immobility, and achieve the effects of convenient instrumentation, convenient operation, and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

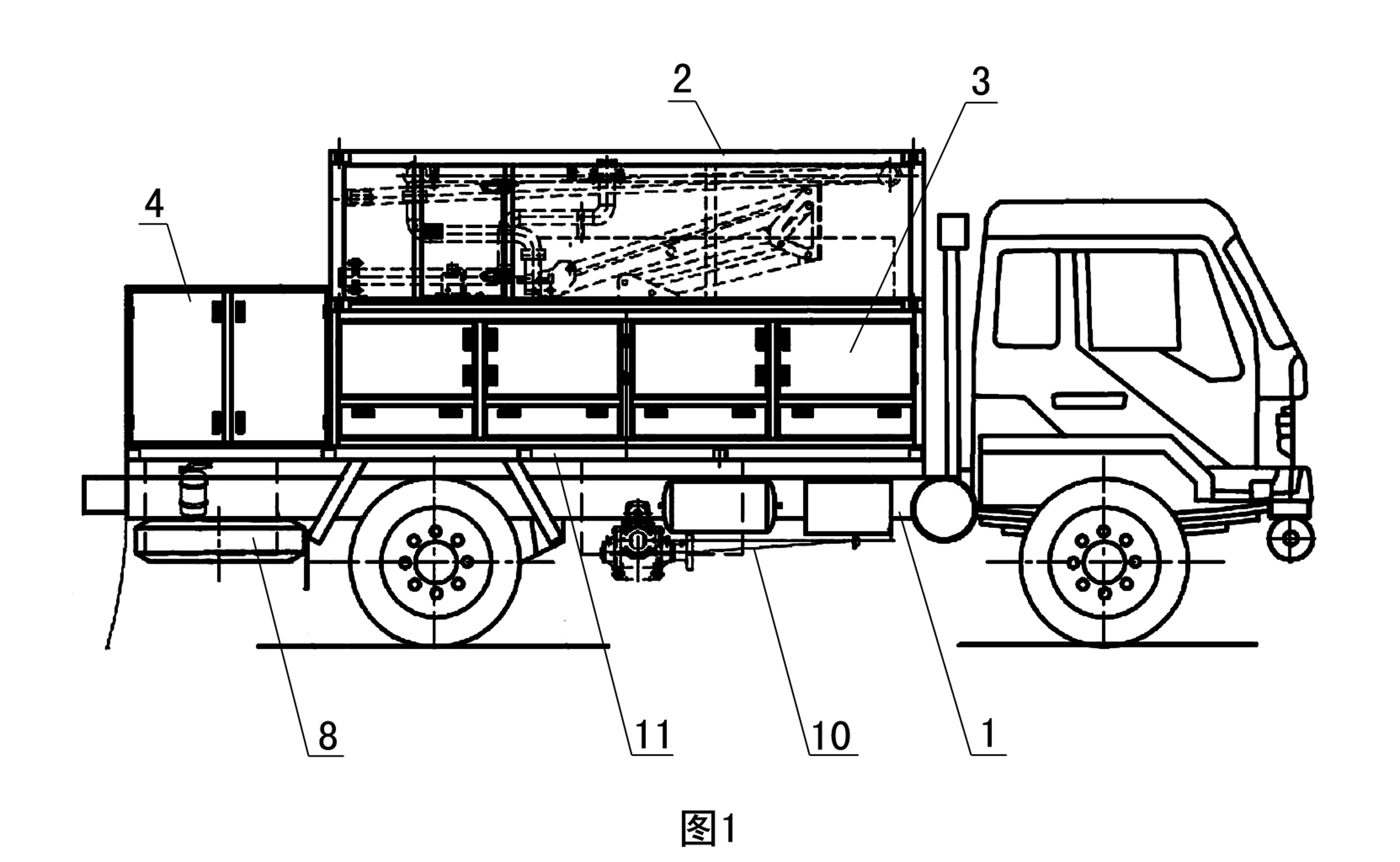

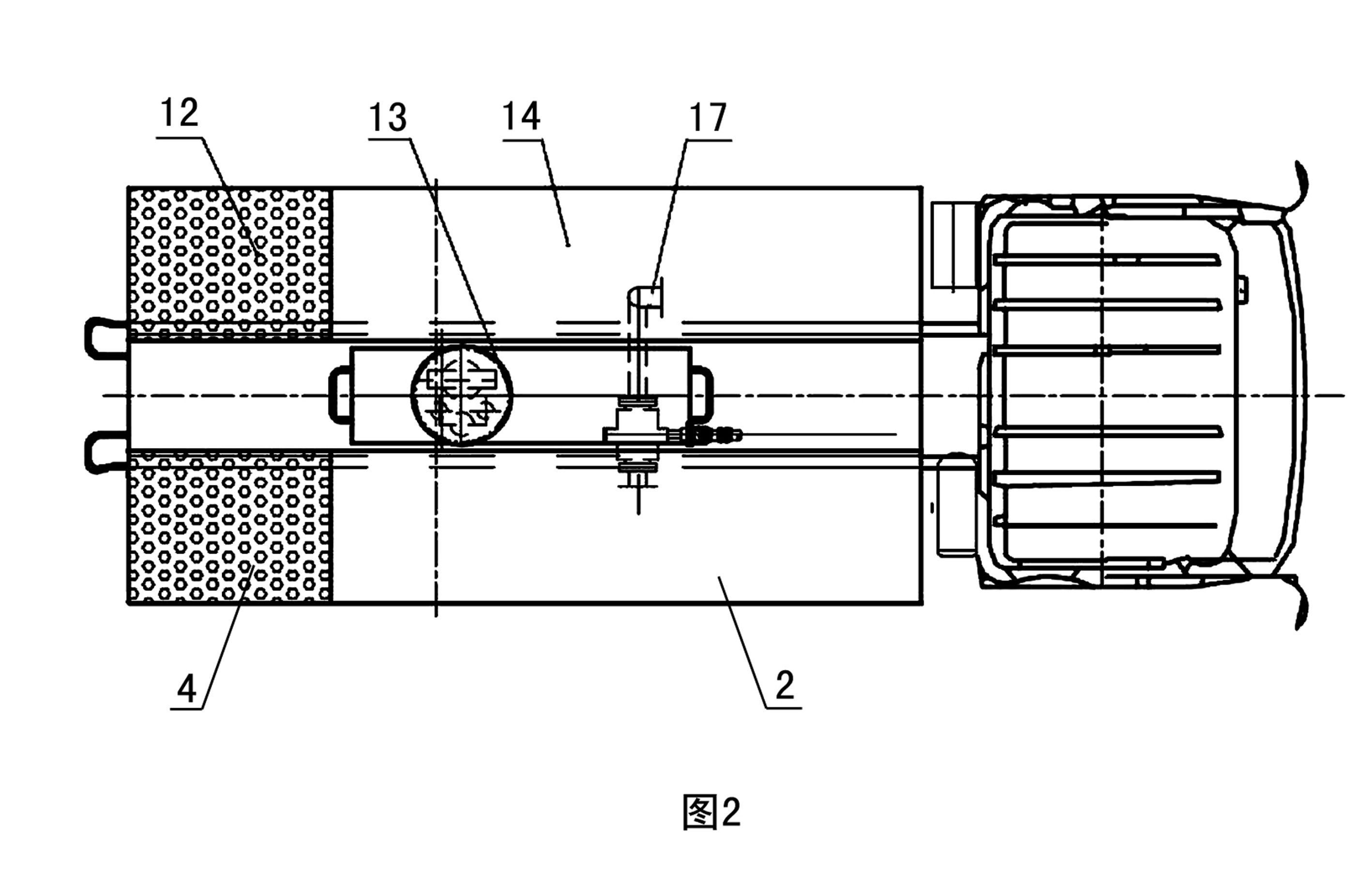

[0045] Examples see figure 1 , figure 2 As shown, this railway oil tank unloading device vehicle is fixedly connected with a platform assembly 11 on the automobile chassis system 1, and the platform assembly 11 is equipped with a control box 4, an electric control box 12, an oil return and discharge fuel tank 13, and an oil pump 20. Crane tube assembly, crane tube box and oil circuit control valve, the control box 4 is connected to the crane tube assembly under drive control, the electric control box 12 is connected to the chassis power take-off system 10, and the chassis power take-off system 10 is driven to connect to the oil pump 20 .

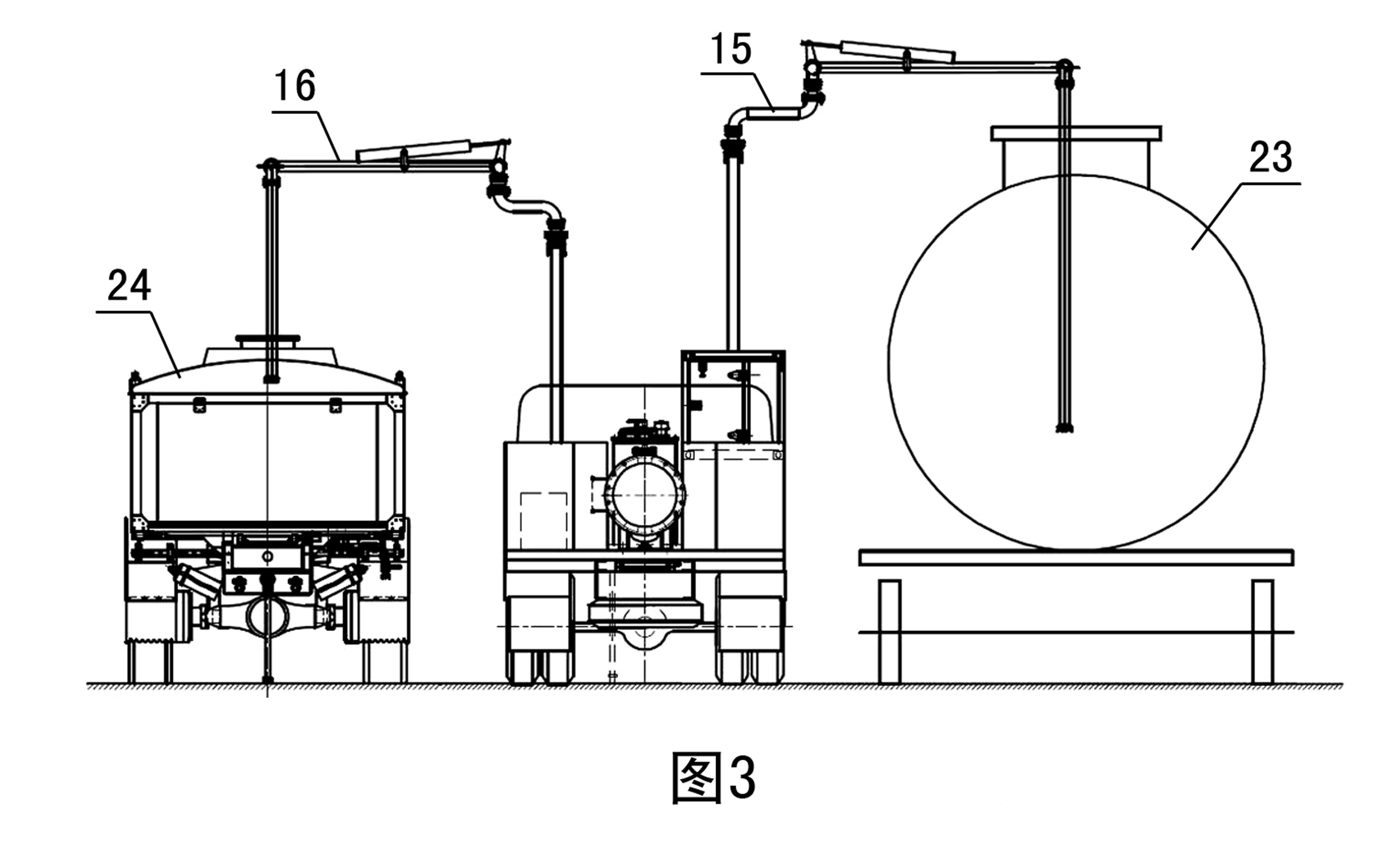

[0046] The crane pipe assembly includes a set of railway oil delivery crane assembly 15, a set of automobile oil delivery crane assembly 16 and one to two sets of bottom filling oil pipe assemblies. The railway oil delivery crane assembly 15 is installed on the railway In the oil tank oil suction crane pipe box 2, the automobile oil deliv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com