System for testing comprehensive performance of reducer for robot joint

A comprehensive performance testing, robot joint technology, applied in the direction of machine gear/transmission mechanism testing, etc., to achieve the effect of good versatility, high testing accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, test system of the present invention is further elaborated:

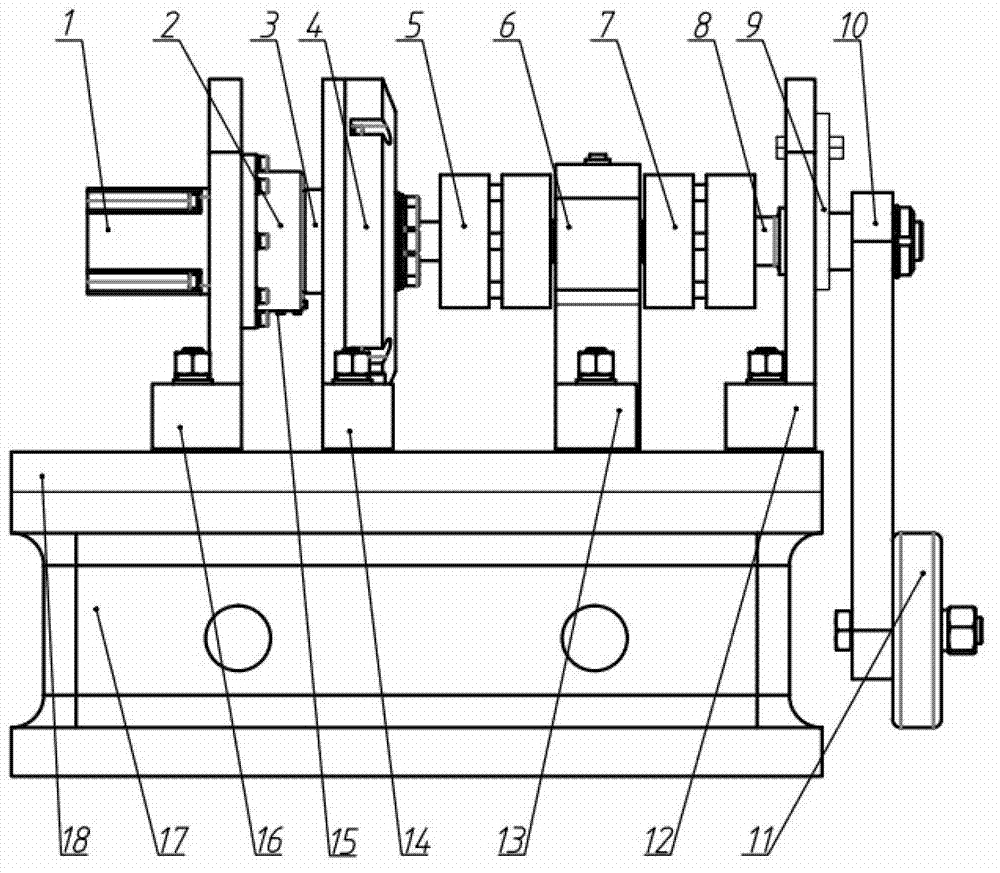

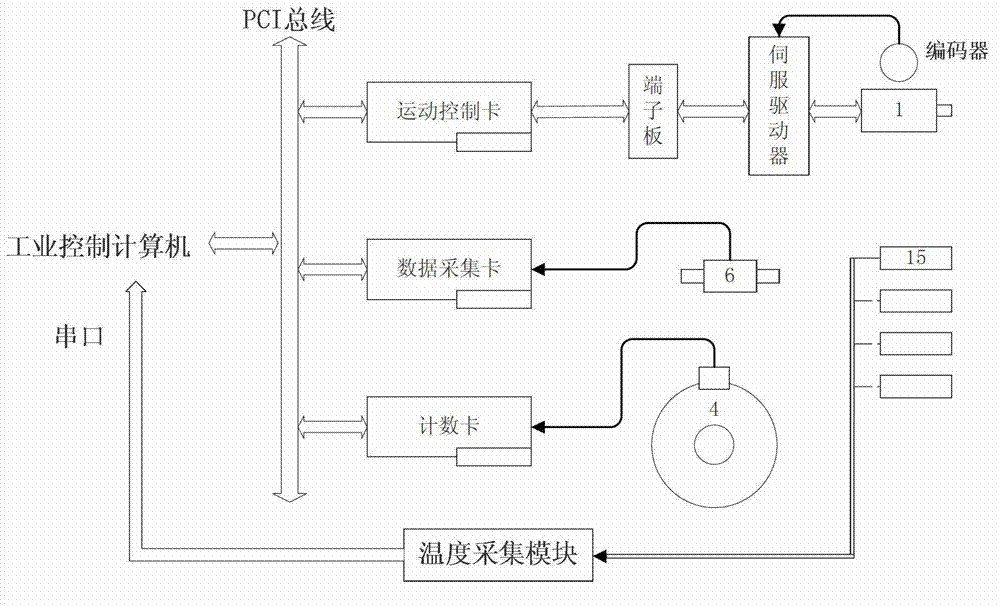

[0020] see figure 1 In the mechanical part, the output shaft of the servo motor 1 is directly connected to the input end of the tested reducer 2, and is fixed on the horizontal guide rail 18 through the first bracket 16, and the horizontal guide rail is fixed on the base 17. The tested reducer 2 is installed with a temperature The sensor 15 measures the temperature. The flange at the output end of the tested reducer 2 is connected to the following components through the first connecting shaft 3. The inner ring of the angle measuring device 4 is sleeved on the first connecting shaft 3 and fastened by a special nut. The outer ring of the angle measuring device 4 The ring is fixed on the horizontal guide rail 18 by the second support 14 . The first connecting shaft 3 is connected to the torque sensor 6 through the first coupling 5, the torque sensor 6 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com