Permanent magnet motor pole protection coating forming process and processing equipment

A technology of process equipment and permanent magnet motors, applied in the manufacture of motor generators, magnetic circuits, electromechanical devices, etc., can solve problems such as deterioration of insulation performance, reduction of withstand voltage level and life, deterioration of electrical performance and mechanical performance of motor insulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

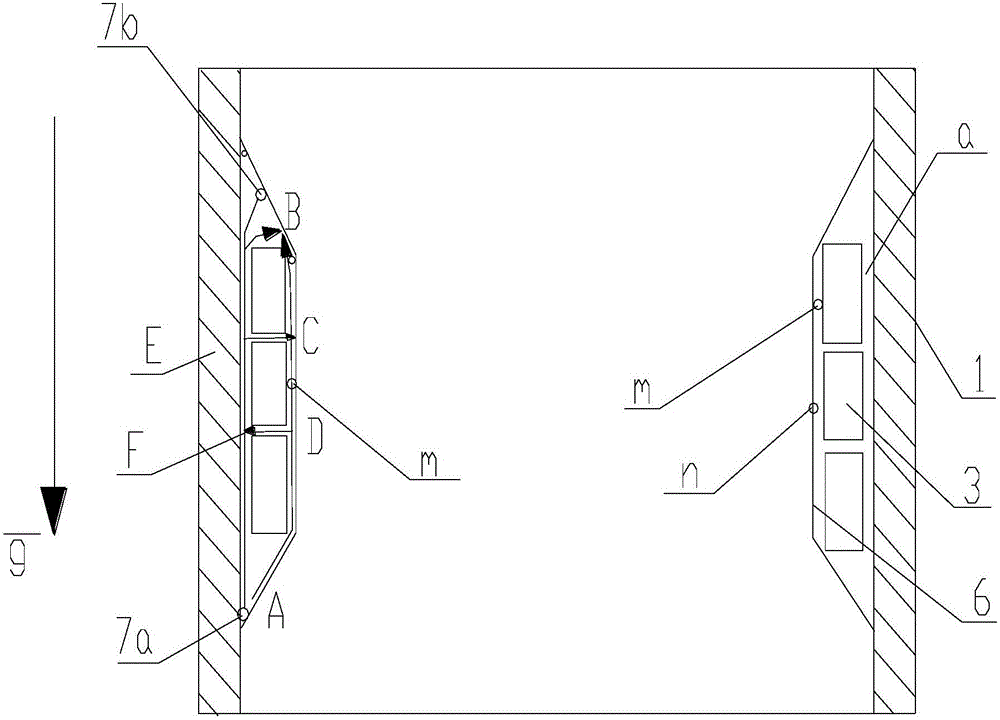

[0200] In this paper, the four horizontal cantilevers are respectively defined as the first horizontal cantilever 90221, the second horizontal cantilever 90222, the third horizontal cantilever 90223 and the fourth horizontal cantilever 90224. The 12 o'clock direction and the 3 o'clock direction, that is, the horizontal cantilever module 9022 and the distance measuring sensor 907 are axially arranged one by one.

[0201] please refer again Figure 19 , in a specific implementation manner, there is a group of ranging sensors on the same axis, and a group of ranging sensors includes at least two ranging sensors 907, Figure 19 2 shows a specific embodiment in which a group of distance measuring sensors includes two, and the distance measuring sensors 907 in the same group are arranged at intervals along the same axial direction, and the positions can be arbitrary. This article continues to introduce the technical solution by taking the two ranging sensors 907 in the same group r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com