Method for spraying photoresist

A photoresist and nozzle technology, applied in the direction of photo-engraving process coating equipment, etc., can solve the problem of incomplete filling of patterns, and achieve the effect of saving time, ensuring uniformity and short moving path.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

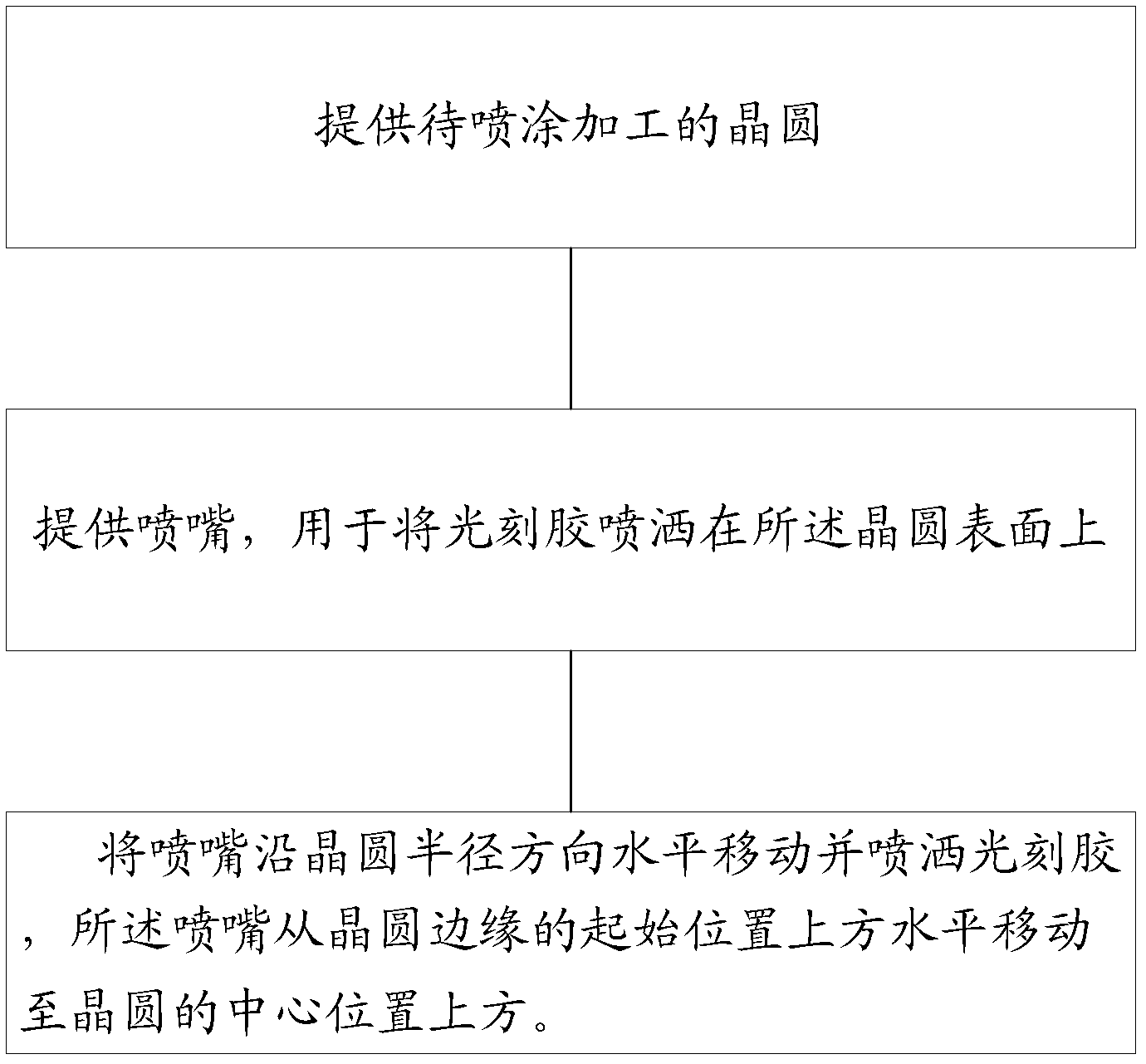

[0049] When the dispensing nozzle moves horizontally from the starting position along the radial direction of the wafer at a constant speed v, the rotation speed r of the wafer remains constant. The nozzle hovers at the start and end positions for a predetermined time, and moves horizontally at a constant speed v at other times.

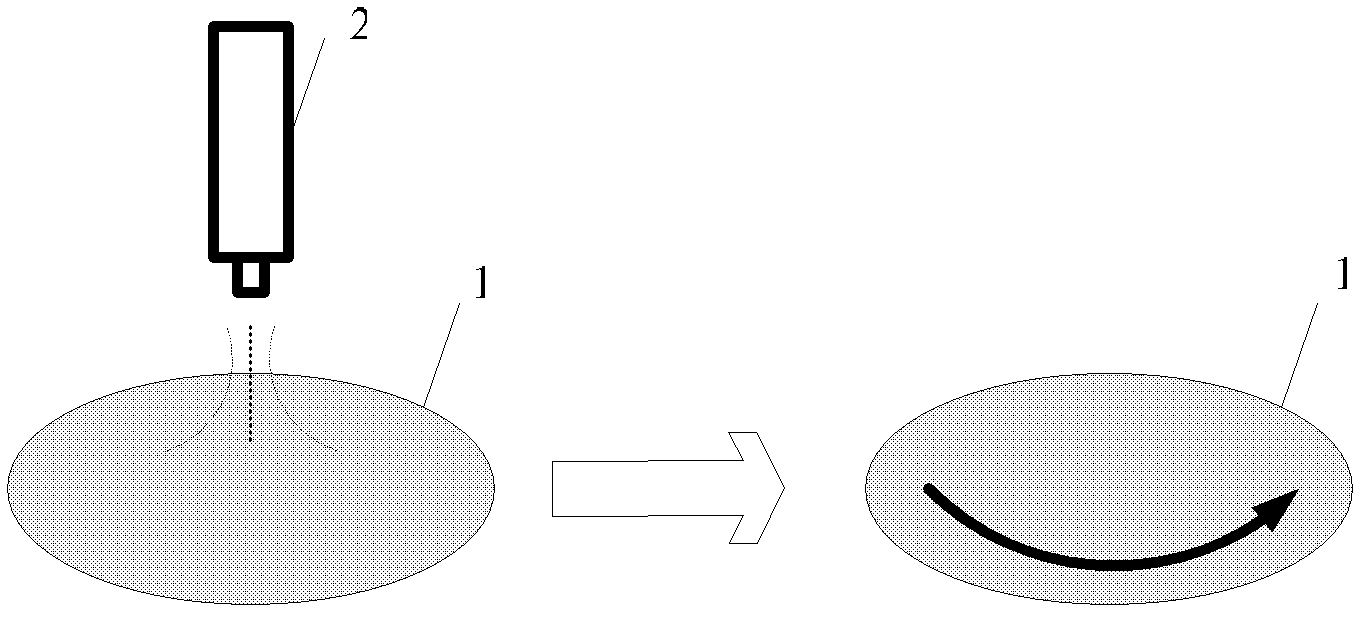

[0050] In this embodiment, the dispensing nozzle moves horizontally along the radial direction from directly above any position in the annular region of the wafer from A to B, and stops above the center position O of the wafer. At this time, the rotation speed of the wafer is r. In the process of spraying photoresist on the above moving path, the nozzle first hovers at the initial position for a predetermined time, then moves horizontally along the radial direction at a constant speed v, and then hovers for a predetermined time above the center position O of the wafer. The photoresist (coating) process is over. At this point, the sprayed photoresis...

Embodiment 2

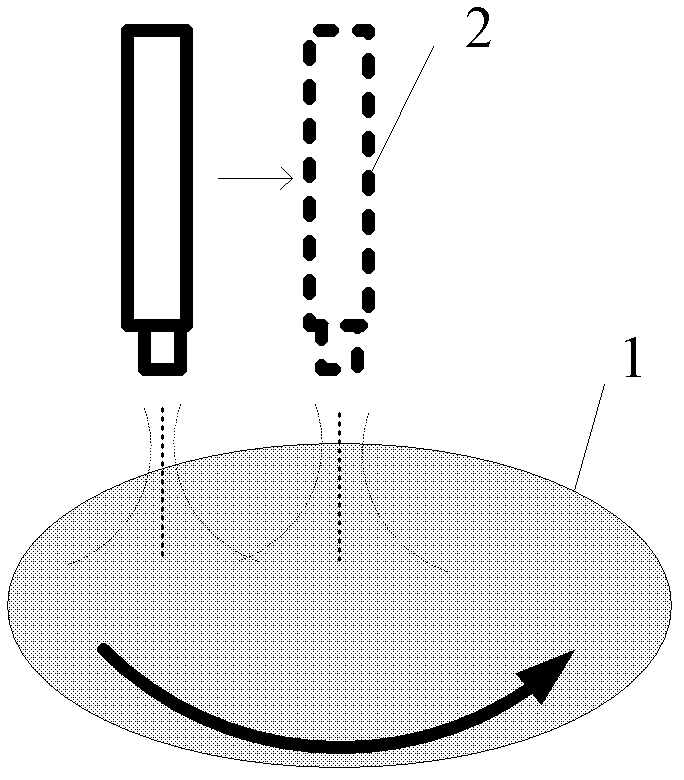

[0059] The difference from Embodiment 1 is that while the dispensing nozzle is moving horizontally, the rotation speed of the wafer can be dynamically adjusted according to the size of the wafer and the size of the graphics formed on the wafer.

[0060] The nozzle moves horizontally at a constant speed. When the nozzle is above the initial position of the wafer edge, the wafer rotates at an initial speed r1; after that, the wafer accelerates to r2 and rotates at a constant speed r2; when the When the nozzle moves horizontally above the center position of the wafer along the radial direction of the wafer, the wafer decelerates to the stop rotation speed r3.

[0061] When the dispensing nozzle moves horizontally from the starting position along the radial direction of the wafer at a constant speed v, in this embodiment, the dispensing nozzle moves along the radial direction directly above any position in the annular region from A to B of the wafer. direction to move horizontally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com