Mobile type hydraulic airtight filling device

A filling device and mobile technology, which is applied in the direction of filling materials, safety devices, mining equipment, etc., can solve the problems of low resource recovery rate, low production efficiency, low filling efficiency, etc., to reduce costs, save labor, and improve filling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

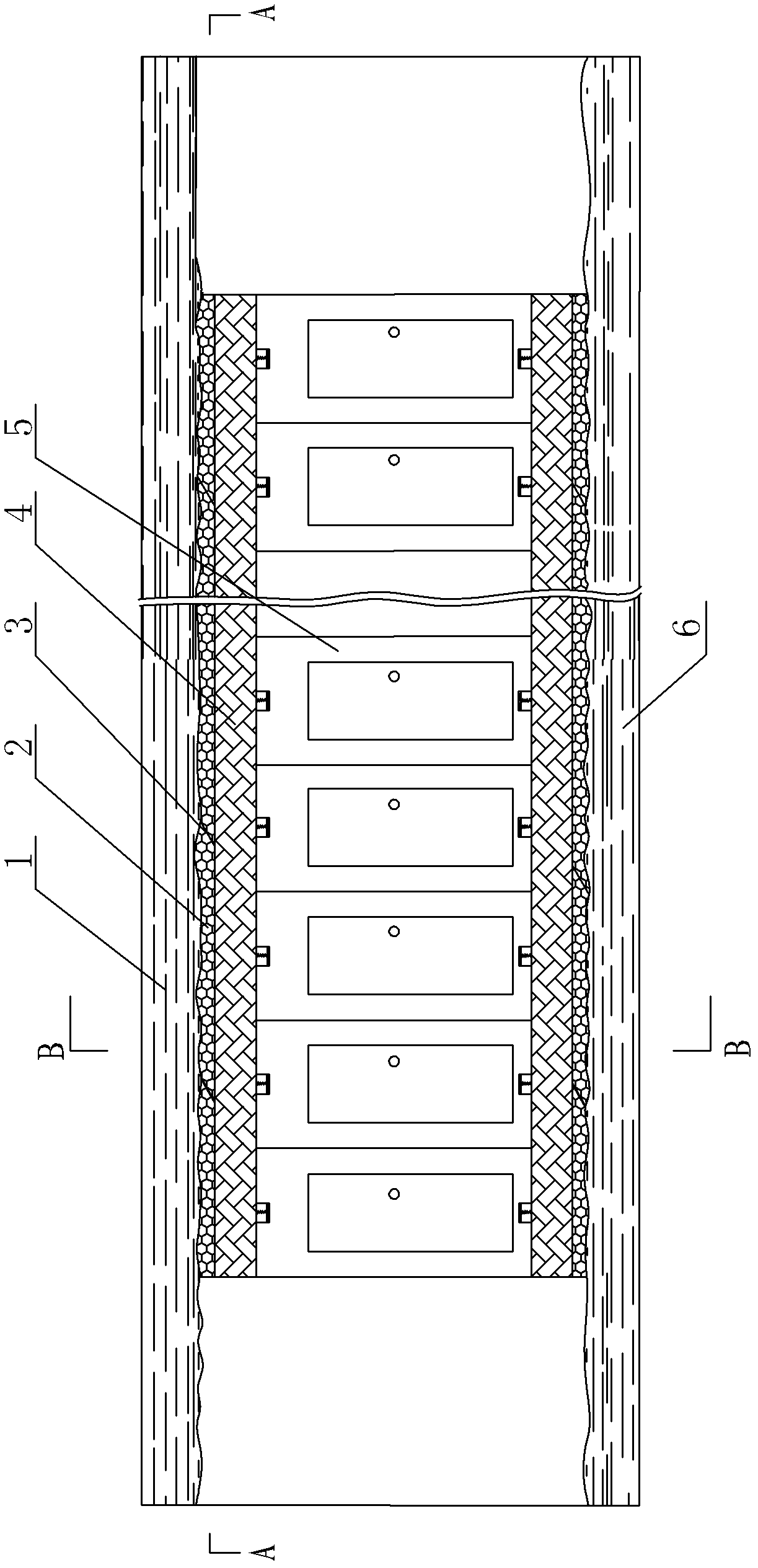

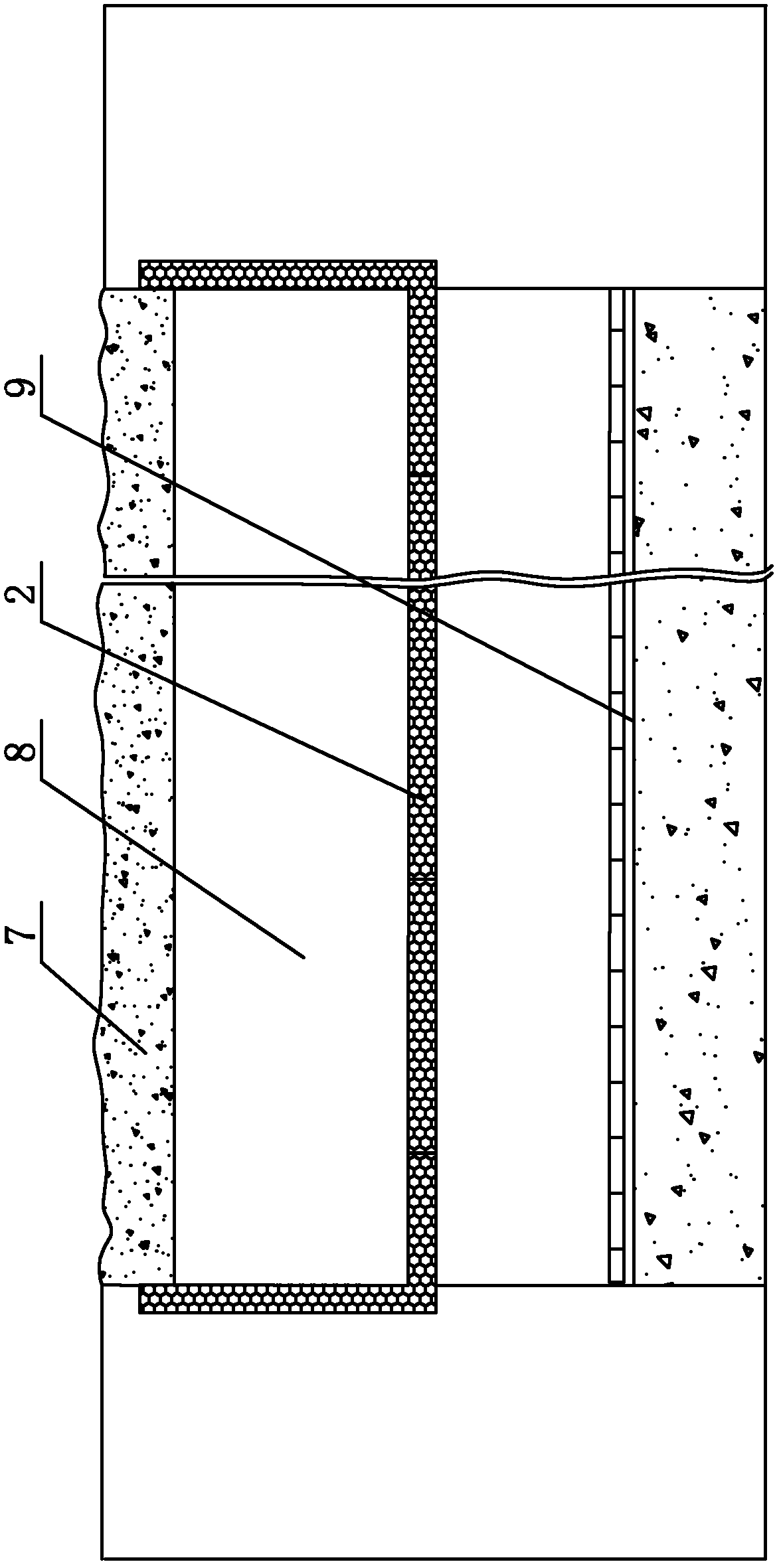

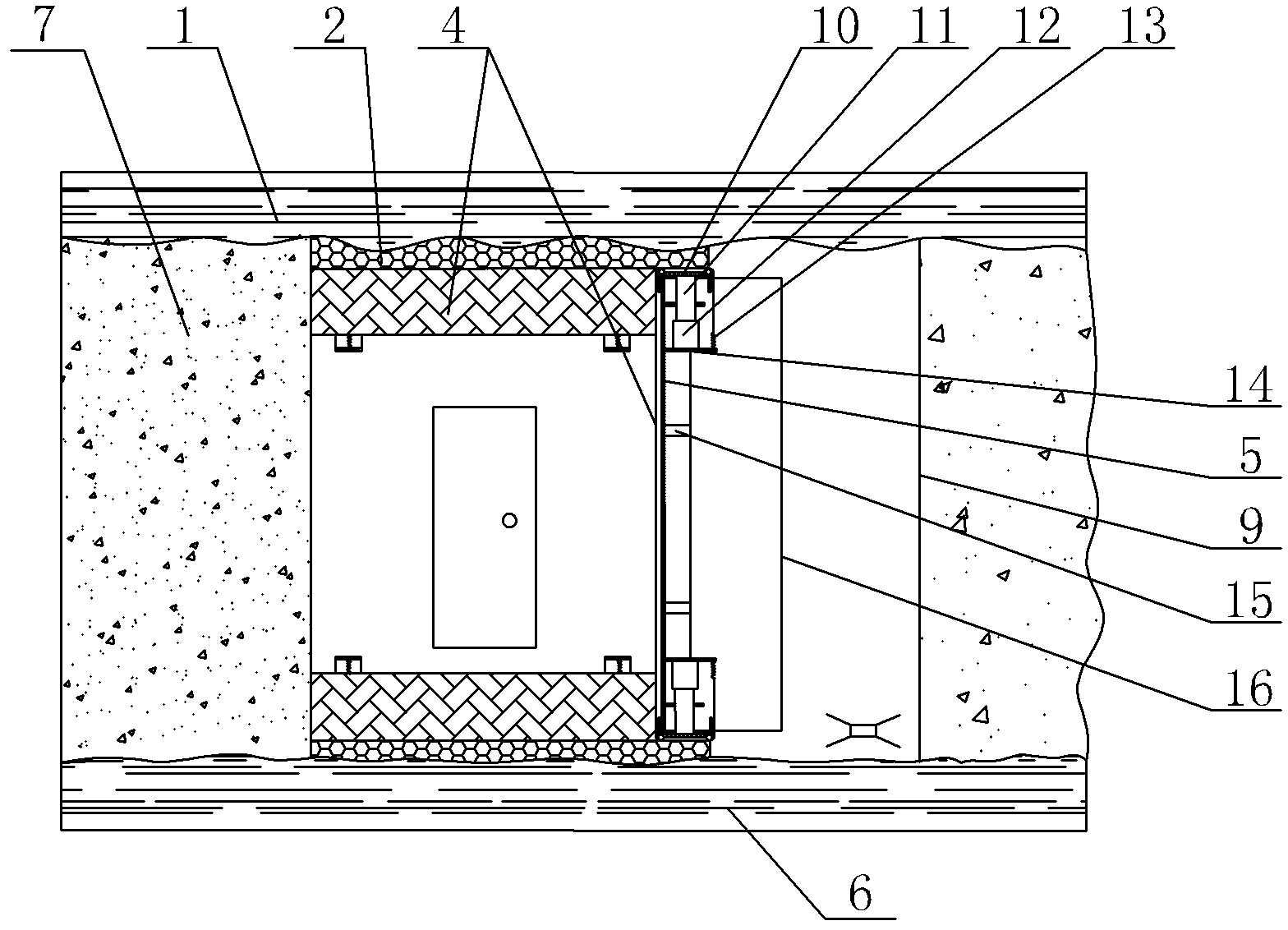

[0021] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0022] Such as Figure 1~5 As shown, the mobile hydraulic airtight filling device includes several groups of hydraulic supports 16 arranged in parallel, the rear end of each group of hydraulic supports 16 is connected to the vertical retaining wall 5 of the hard plate through the beam 15, and the hydraulic supports 16 are respectively passed through the support plate 14 is fixedly installed with upper and lower two hydraulic cylinders 12 facing away from each other. The top end of the piston rod 11 of the hydraulic cylinder 12 is fixed with an adjustment plate 10. The adjustment plate 10 includes a horizontal pressing plate 20 perpendicular to the piston rod 11 and two welded horizontal pressing plates 20. end and parallel to the two vertical plates 22 of the piston rod 11, the horizontal platen 20 is fixed on the top of the piston rod 11, the vertical plate 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com