Stuffed food forming method

A technology for food forming and stuffing, which is applied in food science, baking, and dough processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] A method for forming stuffed food, characterized in that it comprises the following steps:

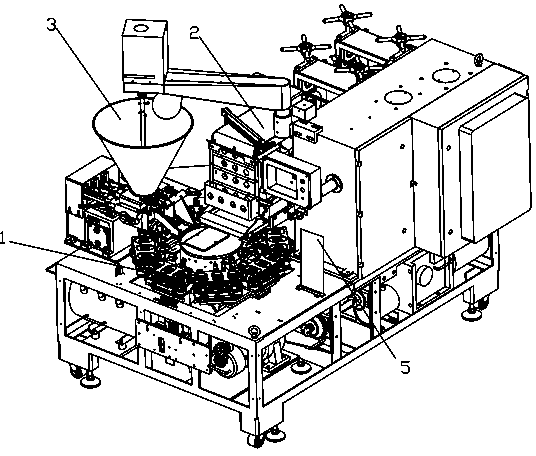

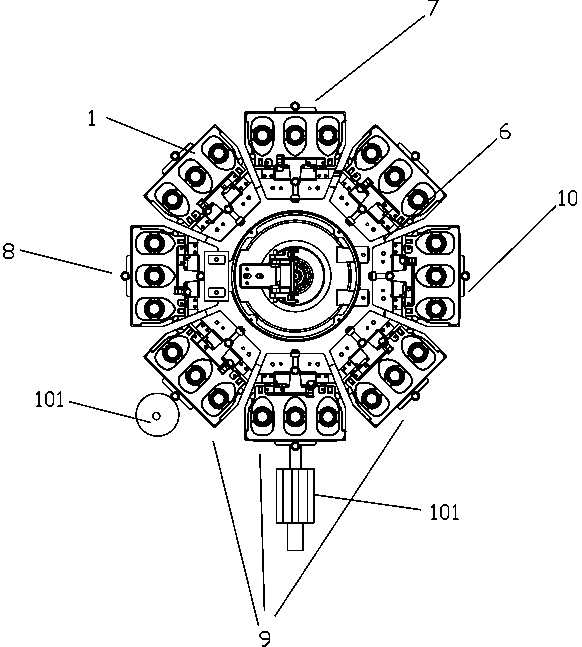

[0079] In the first step, the skin receiving plate 1 is located at the skin receiving station 7 of the circular track 6, and the dough conveying device 3 transports the dough to the skin receiving station 7 at the skin receiving station 1;

[0080] The skin plate 1 and the clamping device 2 below it move on the circular track 6 at the same time;

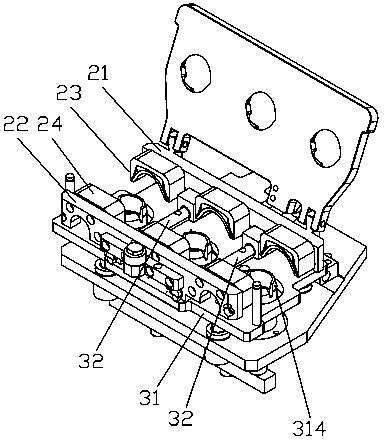

[0081] In the second step, the skin connecting plate 1 and the clamping device 2 move on the circular track 6 to the filling station 8, and the filling device injects the filling on the upper surface of the dough; while injecting the filling, push the filling downward, Make the dough be U-shaped; the position of the connecting plate 1 and the fixed plate 31 on the clamping device 2 is lowered, and the connecting plate 1 is lowered to the upper end of the mold cup 314 of the clamping device 2;

[0082] In the third step, the skin plate...

Embodiment 2

[0087] A method for forming stuffed food, characterized in that it comprises the following steps:

[0088] In the first step, the skin receiving plate 1 is located at the skin receiving station 7 of the circular track 6, and the dough conveying device 3 transports the dough to the skin receiving station 7 at the skin receiving station 1;

[0089] The skin plate 1 and the clamping device 2 below it move on the circular track 6 at the same time;

[0090]In the second step, the skin connecting plate 1 and the clamping device 2 move on the circular track 6 to the filling station 8, and the filling device injects the filling on the upper surface of the dough; while injecting the filling, push the filling downward, Make the dough be U-shaped; the position of the connecting plate 1 and the fixed plate 31 on the clamping device 2 is lowered, and the connecting plate 1 is lowered to the upper end of the mold cup 314 of the clamping device 2;

[0091] In the third step, the skin plate ...

Embodiment 3

[0098] A method for forming stuffed food, characterized in that it comprises the following steps:

[0099] In the first step, the skin receiving plate 1 is located at the skin receiving station 7 of the circular track 6, and the dough conveying device 3 transports the dough to the skin receiving station 7 at the skin receiving station 1;

[0100] The skin plate 1 and the clamping device 2 below it move on the circular track 6 at the same time;

[0101] In the second step, the skin connecting plate 1 and the clamping device 2 move on the circular track 6 to the filling station 8, and the filling device injects the filling on the upper surface of the dough; while injecting the filling, push the filling downward, Make the dough be U-shaped; the position of the connecting plate 1 and the fixed plate 31 on the clamping device 2 is lowered, and the connecting plate 1 is lowered to the upper end of the mold cup 314 of the clamping device 2;

[0102] In the third step, the skin plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com