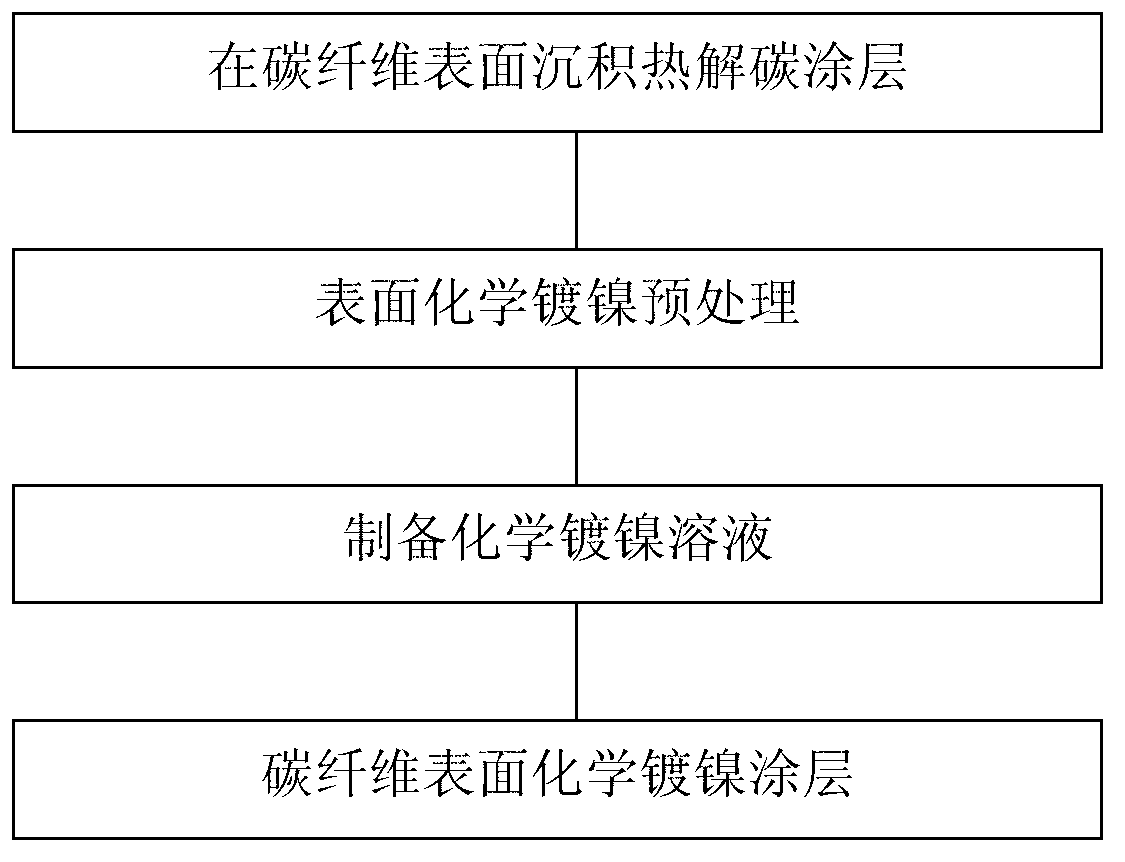

Preparation method of continuous carbon fiber surface pyrolytic carbon/nickel composite coating

A composite coating and carbon fiber technology, applied in the field of materials, can solve the problems of long cycle, affecting carbon fiber reinforced metal matrix composite materials, low efficiency, etc., and achieve the effects of preventing oxidation, improving the effect of homogenization and infiltration, and improving the effect of preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is a method for preparing a pyrolytic carbon / nickel composite coating on the surface of continuous carbon fibers, and the carbon fibers used in this example are 12K T700 carbon fibers.

[0030] The concrete steps of this embodiment are:

[0031] Step 1, depositing a pyrolytic carbon coating on the surface of the carbon fiber. The 12K T700 carbon fiber was placed in a chemical vapor deposition furnace, and a pyrolytic carbon coating was deposited by a conventional chemical vapor deposition method. Coating process parameters are: N 2 The penetration is 0.1~0.5m 3 / h,CH 4 The feed rate is 16-24L / h, the deposition temperature is 1000-1200°C, and the deposition time is 1-3 hours. After the chemical vapor deposition furnace is cooled to room temperature, the carbon fiber is taken out to obtain a carbon fiber with a pyrolytic carbon coating on the surface. . In this example, N 2 The throughput is 0.1m 3 / h,CH 4 The throughput is 18 L / h, the deposition temp...

Embodiment 2

[0044] This example is a method for preparing a pyrolytic carbon / nickel composite coating on the surface of continuous carbon fibers, and the carbon fibers used in the example are 3K T300 carbon fibers.

[0045] The concrete steps of this embodiment are:

[0046] Step 1, depositing a pyrolytic carbon coating on the surface of the carbon fiber. The 3K T300 carbon fiber was placed in a chemical vapor deposition furnace, and a pyrolytic carbon coating was deposited by a conventional chemical vapor deposition method. Coating process parameters are: N 2 The penetration is 0.1~0.5m 3 / h,CH 4 The feed rate is 16-24L / h, the deposition temperature is 1000-1200°C, and the deposition time is 1-3 hours. After the chemical vapor deposition furnace is cooled to room temperature, the carbon fiber is taken out to obtain a carbon fiber with a pyrolytic carbon coating on the surface. . In this example, N 2 The inflow is 0.3m 3 / h,CH 4 The throughput is 20 L / h, the deposition temperature...

Embodiment 3

[0059]This example is a method for preparing a pyrolytic carbon / nickel composite coating on the surface of continuous carbon fibers, and the carbon fibers used in this example are 6K T700 carbon fibers.

[0060] The concrete steps of this embodiment are:

[0061] Step 1, depositing a pyrolytic carbon coating on the surface of the carbon fiber. The 6K T700 carbon fiber was placed in a chemical vapor deposition furnace, and a pyrolytic carbon coating was deposited by a conventional chemical vapor deposition method. Coating process parameters are: N 2 The penetration is 0.1~0.5m 3 / h,CH 4 The feed rate is 16-24L / h, the deposition temperature is 1000-1200°C, and the deposition time is 1-3 hours. After the chemical vapor deposition furnace is cooled to room temperature, the carbon fiber is taken out to obtain a carbon fiber with a pyrolytic carbon coating on the surface. . In this example, N 2 The inflow is 0.5m 3 / h,CH 4 The throughput is 24 L / h, the deposition temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com