Method for improving filling capacity of wafer channel

A technology of filling ability and trench, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effect of avoiding hole defects and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical content of the present invention, specific embodiments are given and described as follows in conjunction with the accompanying drawings.

[0037] The invention proposes a method for improving the filling capacity of the wafer trench, which can effectively meet the technical requirements of higher aspect ratio in the new technology.

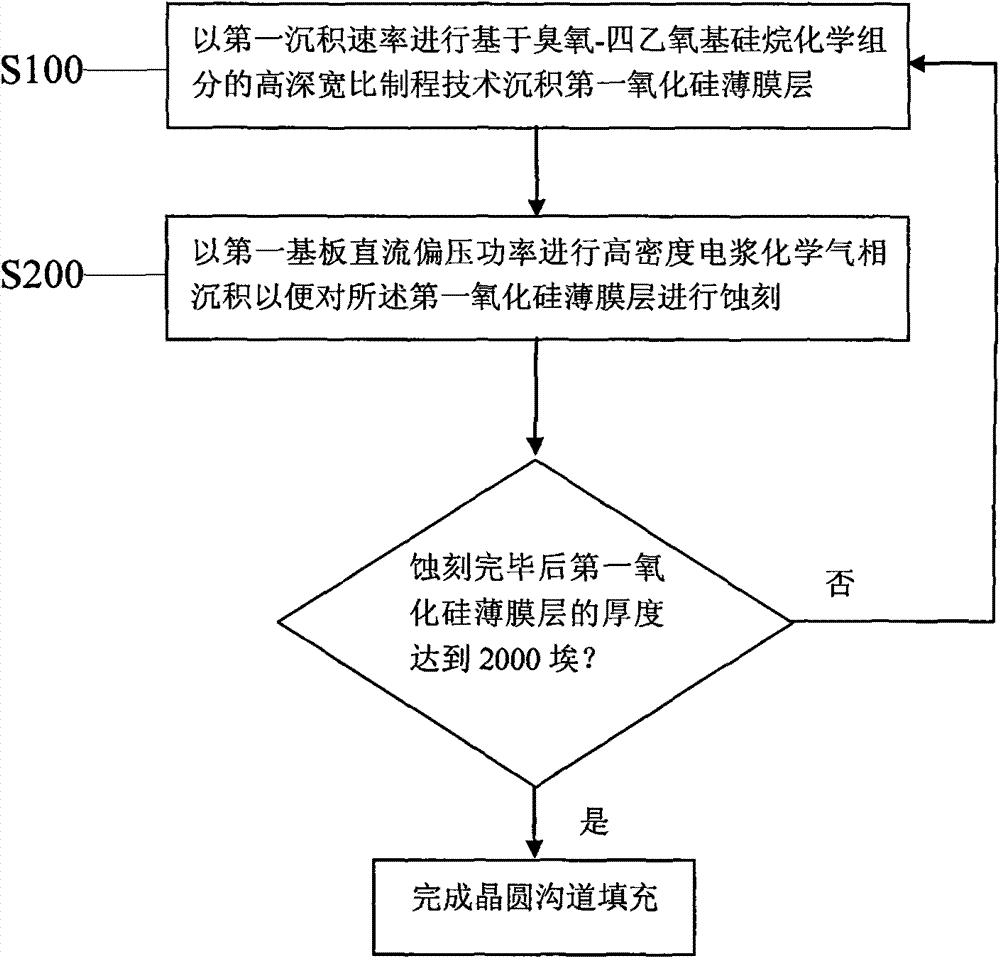

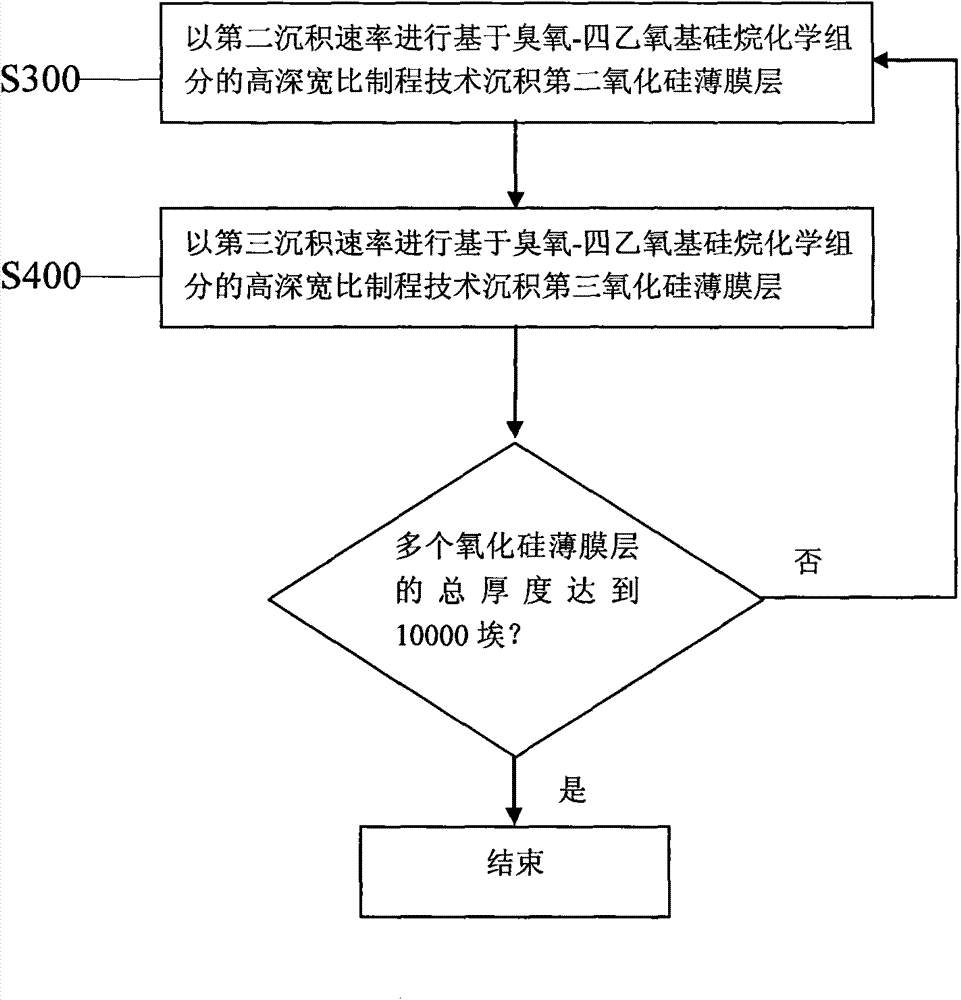

[0038] Please refer to figure 1 , figure 1 Shown is a flow chart of a method for improving the trench filling capability of a wafer according to a preferred embodiment of the present invention. The present invention proposes a method for improving the filling capability of the wafer trench, wherein a trench is formed on the wafer, and the method comprises the following steps:

[0039] Step S100: Depositing a first silicon oxide thin film layer in the trench with a high aspect ratio process technology based on the chemical composition of ozone-tetraethoxysilane at a first deposition rate;

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com