Cored welding wire for preparing ceramic-intermetallic compound cladding layer and method thereof

A technology of intermetallic compound and cladding layer, which is applied in the field of preparation of powder cored welding wire and welding wire for preparing ceramic-intermetallic compound cladding layer, which can solve problems such as poor interface wettability, poor ceramic dispersion, and poor thermal stability, and achieve cost reduction. Low, complete reaction, avoid the effect of hole defects or impurities

Inactive Publication Date: 2011-01-05

NORTH CHINA ELECTRIC POWER UNIV (BAODING)

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The method of directly adding ceramic particles as a reinforcing phase has disadvantages such as poor interfacial wettability, poor ceramic dispersion, segregation, and poor thermal stability.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

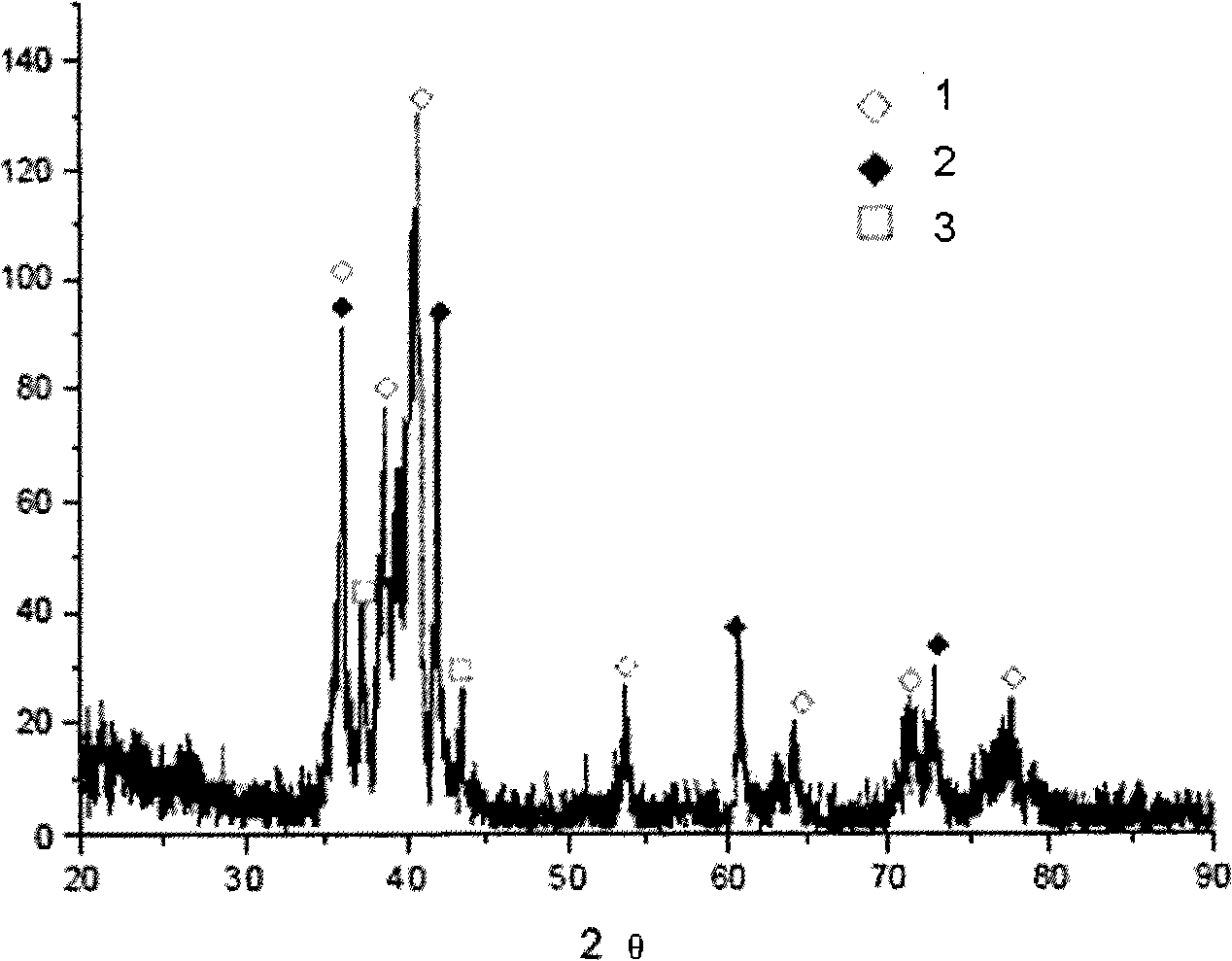

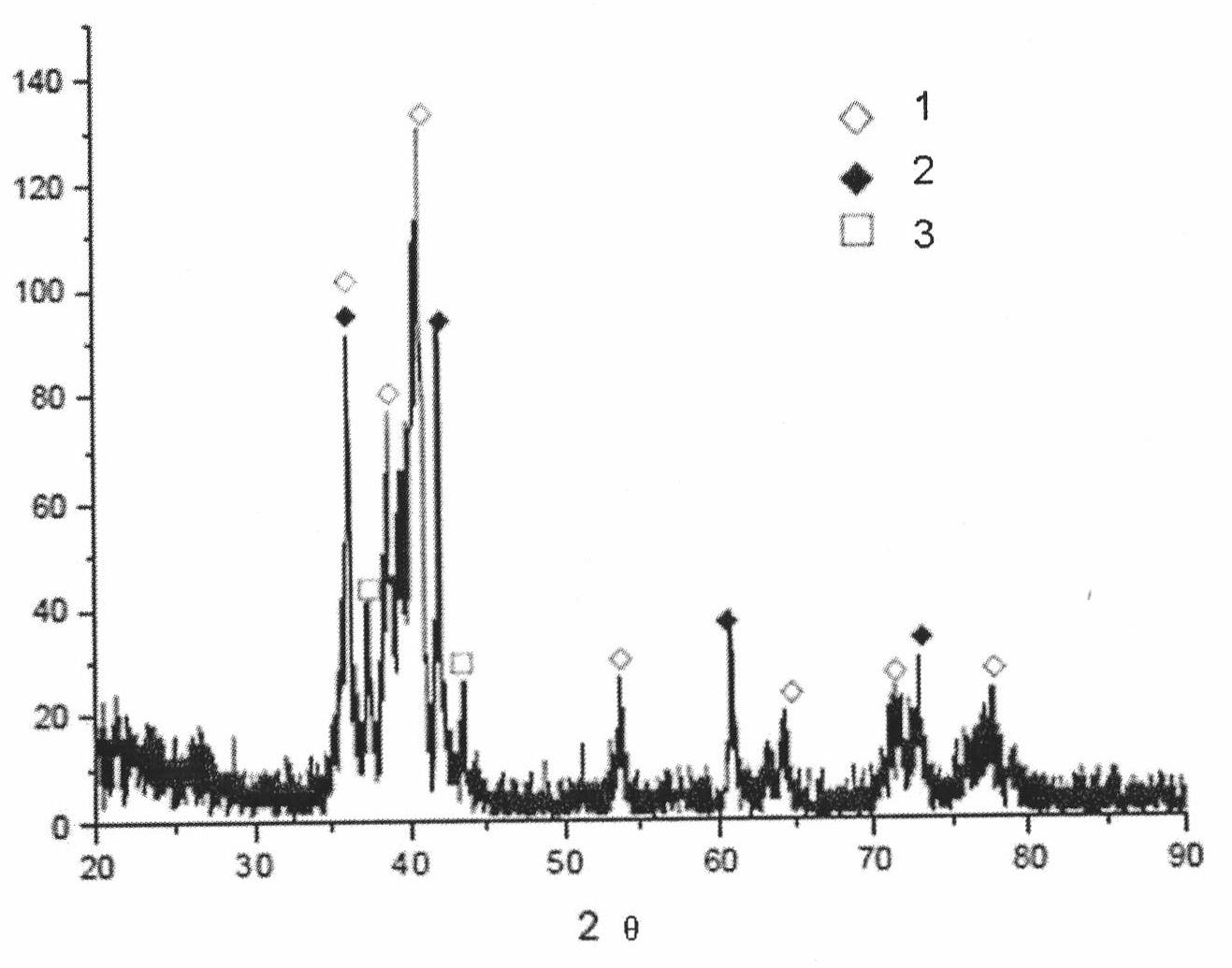

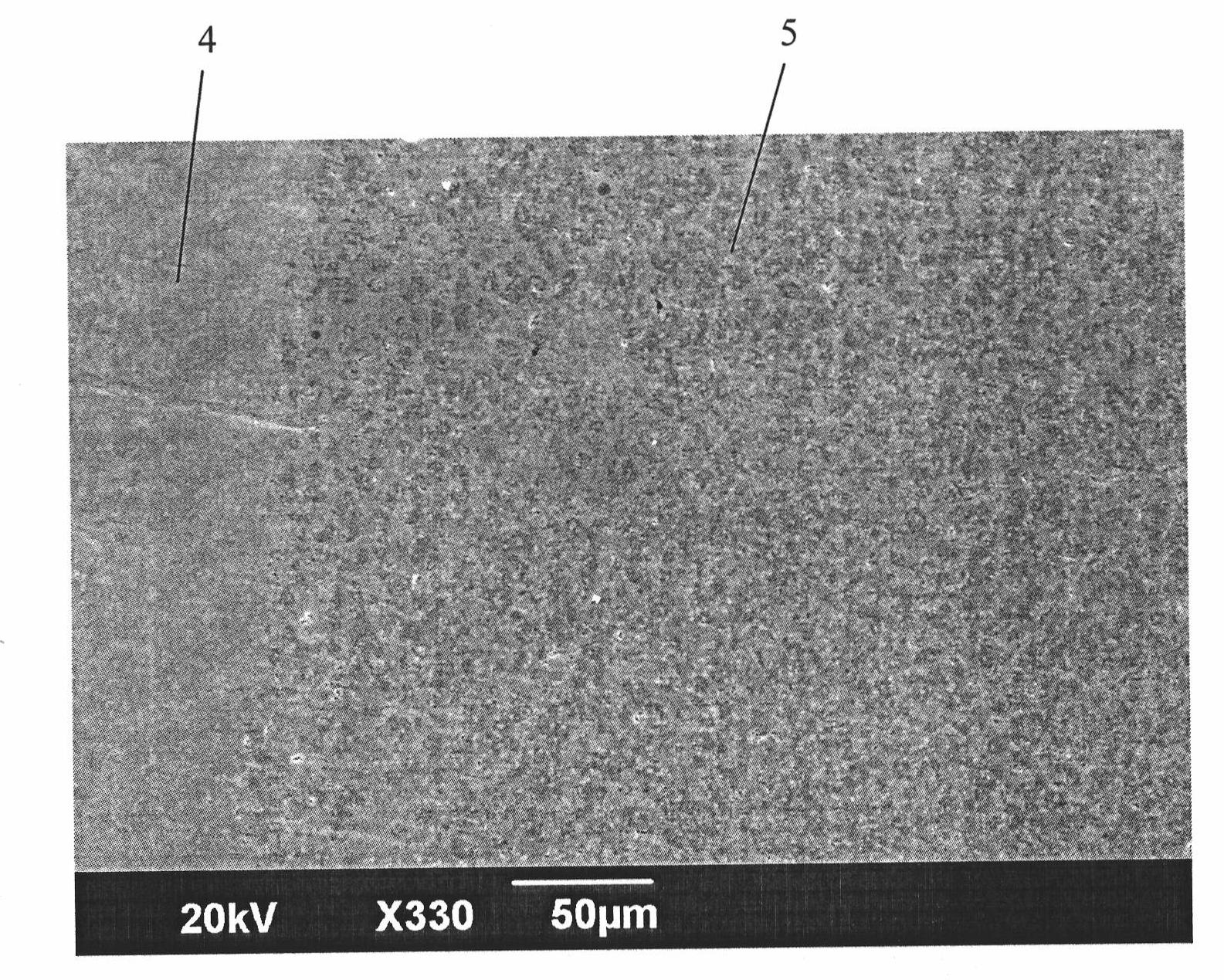

The invention relates to a cored wire for preparing ceramic-intermetallic compound cladding layer and a method thereof, belonging to the technical field of surface engineering. Composition powder material in the cored wire consists of powder of C, Ti, Cr and NbC. Contents of the power are as follows: 10-13wt. % of C powder, 0-3wt. % of Cr powder, 1-2wt. % of NbC powder and balance of Ti powder. Aluminum foil is used to package the composition powder, so as to form a cored welding wire. Weight percentage of the composition powder in the cored welding wire is 90-91wt. %; and a gon-arc welding torch is used to melt and cover the cored wire on the surface of titanium and titanium alloy. The preparing process comprises that aluminum foil is used to package 10-13wt. % of C powder, 0-3wt. % of Cr powder, 1-2wt. % of NbC powder and balance of Ti powder. The method has the advantages that advantages of Ti-Al series intermetallic compound and TiC are combined; the prepared melt coat surface is relatively smooth; and the melt coat thickness deviation is smaller than average melt coat by positive and negative 15%.

Description

A kind of powder-cored welding wire for preparing ceramic-intermetallic compound cladding layer and welding wire preparation method technical field The invention belongs to the technical field of surface engineering, in particular to a powder-cored welding wire for preparing a ceramic-intermetallic compound cladding layer and a preparation method for the welding wire. TiC-Ti3Al is synthesized on the surface of titanium and titanium alloy substrates by using an AC tungsten argon arc heat source. Powder-cored welding wire for cladding layer of intermetallic compound composite material and preparation process of cladding layer. Background technique Titanium and titanium alloys have the advantages of low density, high specific strength, good corrosion resistance, and good process performance. Widely used in many industrial sectors. However, titanium and titanium alloys have disadvantages such as large friction coefficient, poor wear resistance, and low armor-piercing resistan...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K35/22B23K35/40

Inventor 刘宗德胡卫强戴兰宏

Owner NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com