A kind of electrode slurry capping pretreatment liquid, preparation method and use method

A technology of electrode slurry and pretreatment liquid, which is applied in the direction of coating, etc., can solve the problems of chip exposure of components and internal holes of external electrodes, etc., and achieve the effects of reducing surface tension, increasing wettability, and avoiding hole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

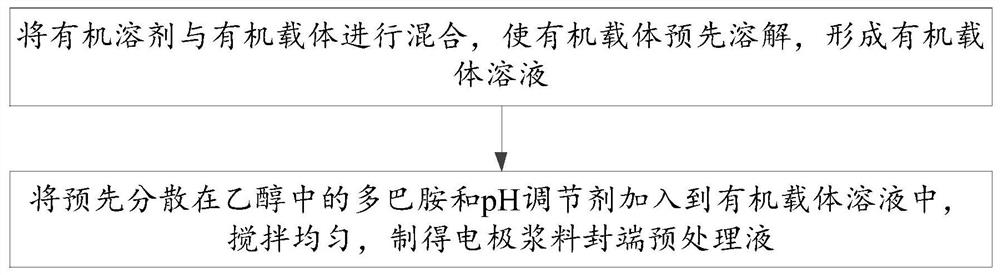

[0051] Such as figure 1 As shown, the present invention provides a method for preparing an electrode slurry end-capping pretreatment solution. The pretreatment solution does not need to be prepared in advance, and can be prepared on site when used; it includes:

[0052] Step 1, mixing the organic solvent and the organic carrier to dissolve the organic carrier in advance to form an organic carrier solution;

[0053] Step 2. Add the dopamine and pH regulator pre-dispersed in ethanol to the organic carrier solution, adjust the pH value between 7 and 8, and stir evenly to prepare the electrode slurry end-capping pretreatment solution.

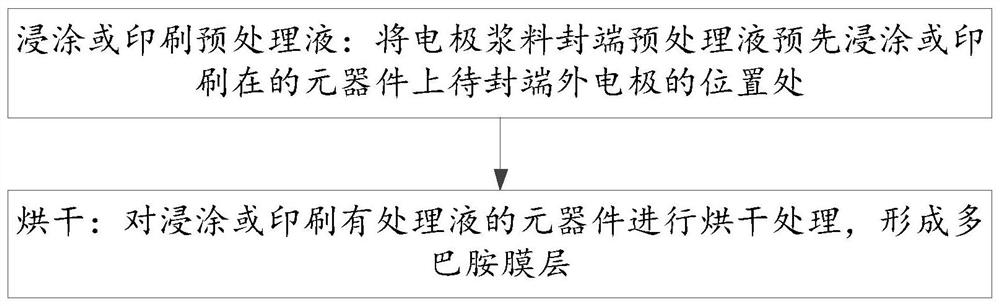

[0054] Such as figure 2 As shown, the present invention provides a method for using an electrode slurry end-capping pretreatment liquid. The pretreatment liquid is used in conjunction with the electrode slurry, before the electrode slurry is used, especially before the external electrode of the component is sealed; including :

[0055] Step 1. ...

Embodiment 1

[0061] The invention provides an electrode slurry end-capping pretreatment liquid, comprising:

[0062] 5.0wt.% of dopamine, 61.9wt.% of ethanol and terpineol mixed solution, 0.1% of lactic acid and lactate (pH regulator) and 33.0wt.% of ethyl cellulose;

[0063] The preparation method of the pretreatment liquid includes: first mixing the mixed solution of 51.9wt.% ethanol and terpineol in a ratio of 1:5 with 33.0wt.% ethyl cellulose, heating at a temperature of 75°C, and mechanically Stir and dissolve for 4h to pre-dissolve the resin; then add a mixture of 10wt.% ethanol, 5.0wt.% dopamine and 0.1% pH regulator lactic acid and lactate to the dissolved organic carrier solution (pH is controlled at 7 ~8), at a rotating speed of 1000rpm, mechanically stir for 1h to obtain a pretreatment solution with a homogeneously mixed viscosity within the range of 45.0Pa.s.

[0064] The method of using the pretreatment liquid includes: a component chip needs to be coated with electrode paste...

Embodiment 2

[0066] The invention provides an electrode slurry end-capping pretreatment liquid, comprising:

[0067] Dopamine 10.0wt.%, 70.0wt.% mixture of terpineol and butyl carbitol, ethanol 10.0wt.%, lactic acid and lactate (pH regulator) 1.0% and acrylic resin 9.0wt.%;

[0068] The preparation method of the pretreatment solution includes: first mixing the mixture of 70.0wt.% terpineol and butyl carbitol with 9.0wt.% acrylic resin, heating at 75°C, and mechanically stirring for 4 hours to make the resin Dissolve in advance; then add a certain amount of 10wt.% ethanol, 10.0wt.% dopamine and 1.0% pH adjuster lactic acid and lactate mixture to the dissolved organic carrier solution (pH is controlled at 7-8), 1000rpm Under the rotating speed of 1 hour, mechanically stir for 1 hour to obtain the pretreatment liquid with uniform viscosity in the range of 12.0Pa.s.

[0069] The method of using the pretreatment liquid includes: a component chip needs to be coated with electrode paste on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com