Resource reclamation type membrane flue gas desulphurization and denitration device and its technology

A resource recovery, desulfurization and denitrification technology, applied in separation methods, air quality improvement, chemical instruments and methods, etc., can solve problems such as limited adjustment range, difficulty in resisting impact, secondary pollution, etc., achieve wide application range, reduce water vapor , the effect of reducing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

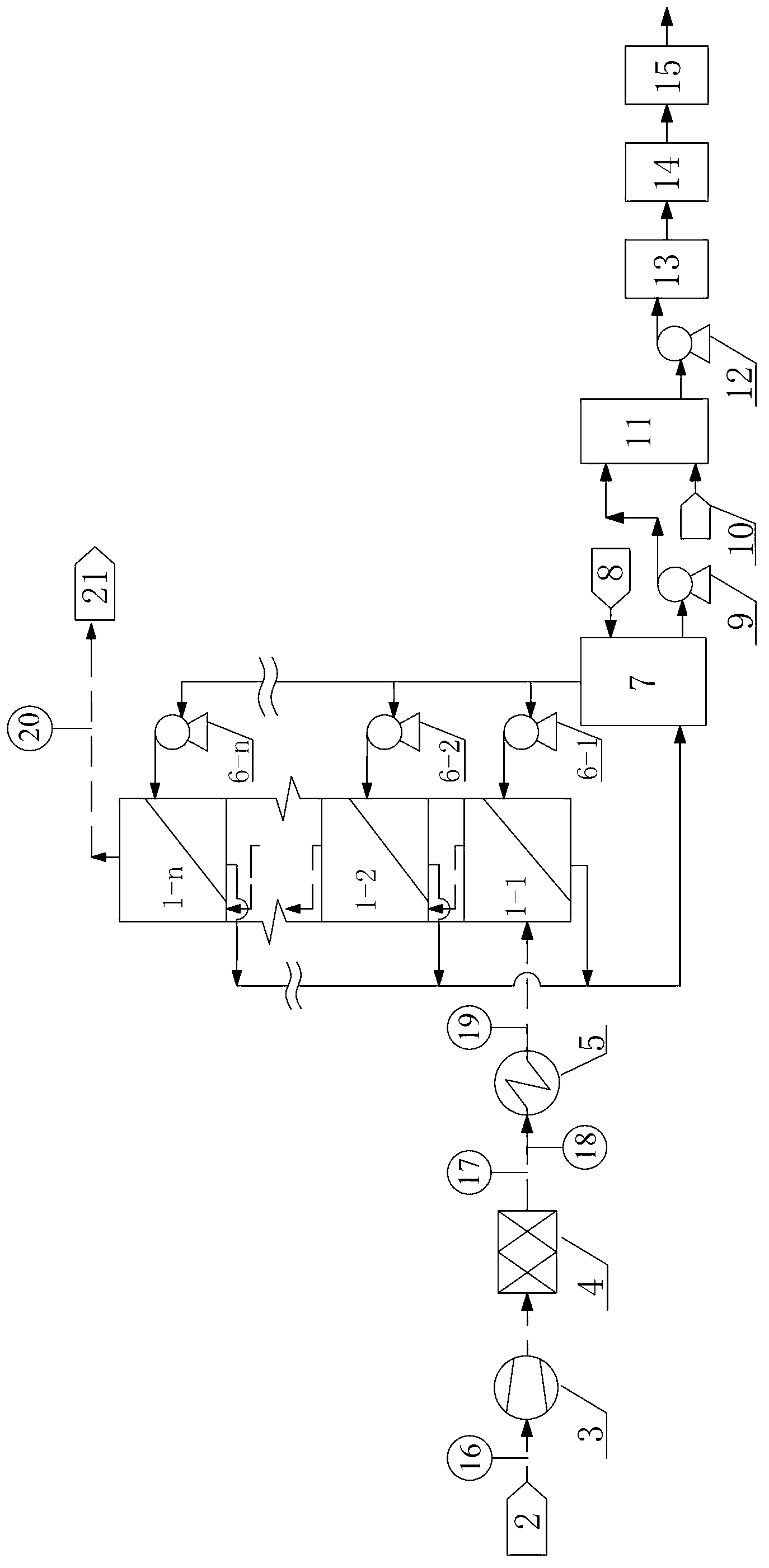

[0061] Embodiment: The resource recovery type membrane flue gas simultaneous desulfurization and denitrification process as shown in the accompanying drawings is adopted, and the core part of the desulfurization and denitrification device is composed of three-stage tank-type membrane contact membrane devices 1-1, 1-2 and 1-3. Assembled directly in series. The hollow fiber membrane filling area of each stage membrane absorber is 500m 2 , the film packing density is about 10%; using the actual coal-fired flue gas pretreated by electrostatic precipitator, its SO 2 The concentration is 1500mg / Nm 3 , NO concentration 600mg / m 3 , NO 2 Concentration 50mg / m 3 , soot concentration 100mg / Nm 3 , temperature 110℃~120℃, flue gas treatment capacity 1000Nm 3 / h. The continuous monitoring device for flue gas components is selected as SWG300 -1 Smoke is in the monitoring system. The oxidant uses a hydrogen peroxide solution with a mass percent concentration of 30%. The oxidized flue...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com