Process for producing phosphoruscopper

A production method and phosphor copper technology, applied in the production field of phosphor copper, can solve the problems of long time, heavy environmental pollution, large investment, etc., and achieve the effects of speeding up the reaction, improving the phosphorus yield and high safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

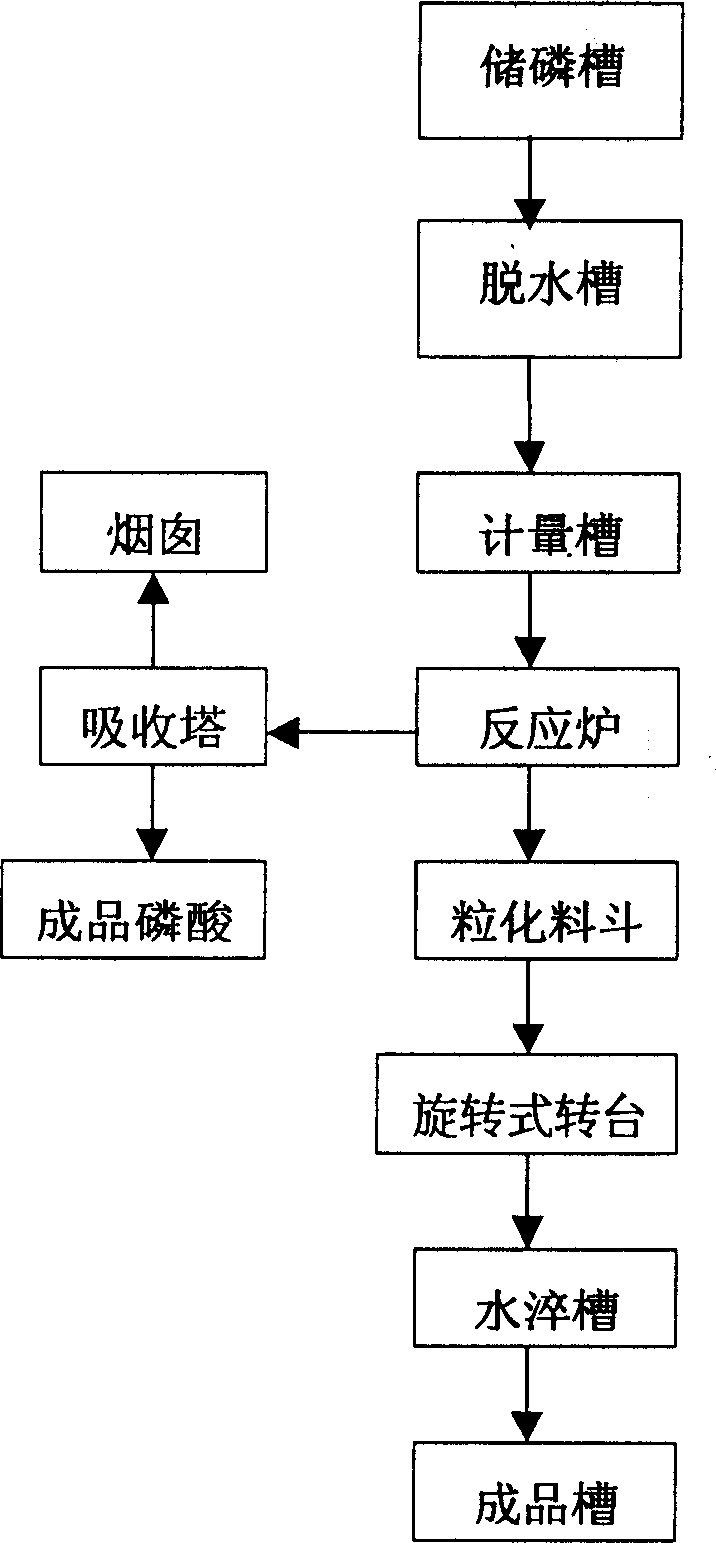

Method used

Image

Examples

Embodiment Construction

[0019] (1) Preparation of dehydrated liquid yellow phosphorus: using solid yellow phosphorus as raw material, add yellow phosphorus to the phosphorus melting tank, melt it with warm water at 60°C, pump it to the high level tank, put it into the drying tank, and heat it to 140°C~160°C with heat transfer oil. Dehydration at ℃, use inert gas as protective gas, control the moisture content of the inert gas outlet of the drying tank to <0.1‰, put the dried liquid yellow phosphorus into the metering tank, and protect it with inert gas;

[0020] (2) Copper melting: put a certain amount of copper in a crucible and heat it to 1200°C until the copper is completely melted;

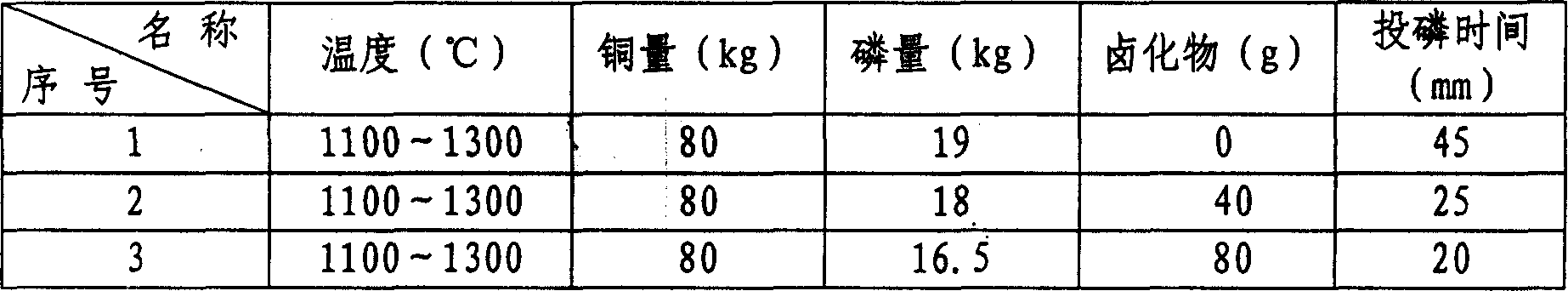

[0021] (3) Compounding reaction: The temperature of the compounding reaction in this process should be controlled at 1200 ° C ~ 1250 ° C, and 0.5‰ ~ 1‰ copper halide is added to the copper liquid or liquid yellow phosphorus as a catalyst, and the amount of yellow phosphorus added is 102 according to stoichiometric % ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com