A kind of catalyst for low-temperature SCR denitrification and preparation method thereof

A catalyst and denitrification technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of expensive catalysts, short service life, high operating temperature, etc., and achieve good catalytic activity, low price, Effect of low ammonia slip rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Catalyst preparation process

[0034] Weigh 240g of titanium dioxide (grain size 20nm), add 48ml of water, stir and mix at 50°C, after mixing evenly, add 24g of ammonium molybdate, the weight ratio of the amount of ammonium molybdate added to titanium dioxide is 1:10, continue stirring Uniformly, the slurry after mixing was continued to stir at this temperature for 2 hours.

[0035] In the slurry obtained above, add 8 g of ammonium metavanadate under stirring, the weight ratio of ammonium metavanadate addition to titanium dioxide is 1:30, then add iron acetate and copper acetate (mass ratio is about 1:1) composition Add 0.8 g of additives, continue to stir for 2 hours, and then ultrasonically vibrate at a frequency of 15 kHz for 30 minutes.

[0036] The treated slurry was dried in a drying oven for 4 hours, and then calcined at 250° C. for 2 hours at 250° C. for 3 hours in a muffle furnace to obtain a catalyst.

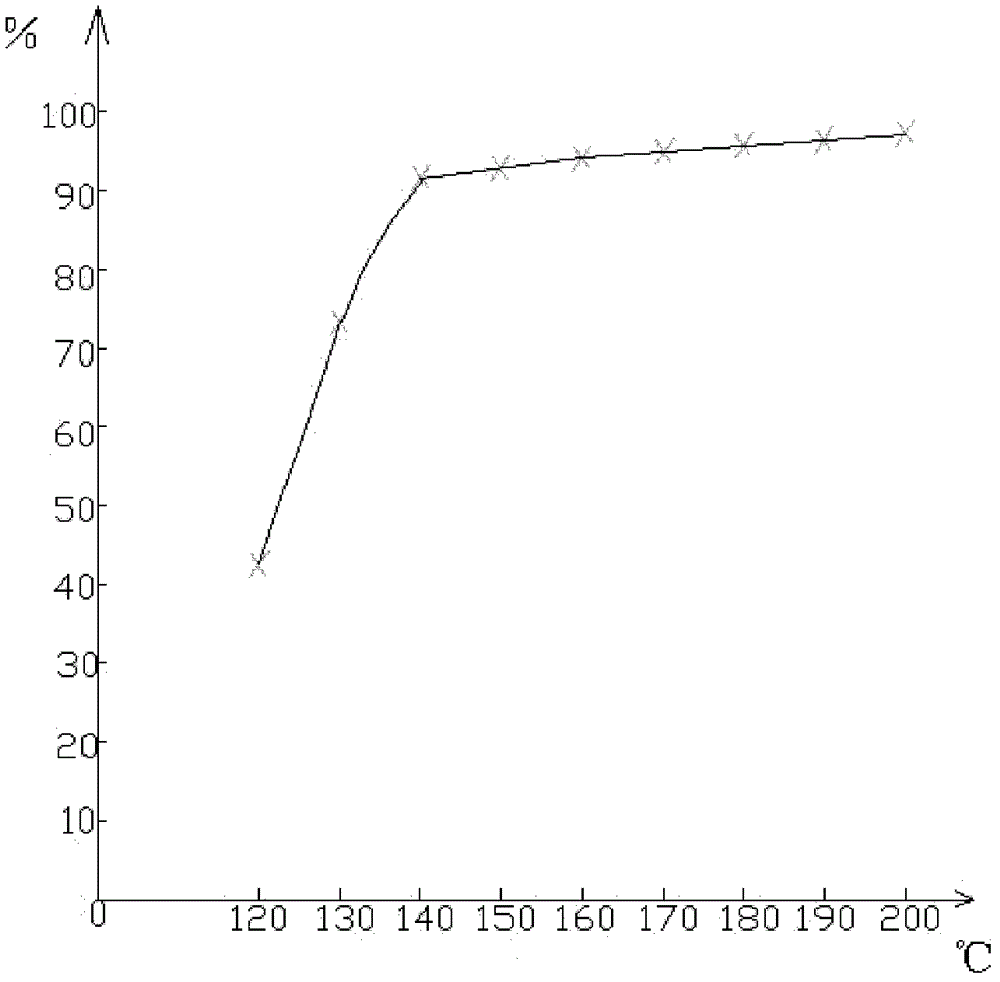

[0037] 2. Catalyst performance test

[0038] The de...

Embodiment 2

[0043] 1. Catalyst preparation process

[0044] Weigh 240g of titanium dioxide (grain size 10nm), add 48ml of water, stir and mix at 70°C, after mixing evenly, add 12g of ammonium molybdate, the weight ratio of ammonium molybdate to titanium dioxide is 1:20, continue stirring Uniformly, the slurry after mixing was continued to stir at this temperature for 2 hours.

[0045] In the slurry obtained above, add 6 g of ammonium metavanadate under stirring, the weight ratio of ammonium metavanadate addition to titanium dioxide is 1:40, then add iron acetate and manganese acetate (mass ratio is about 1:1) composition Auxiliary 4g, continue to stir evenly for 3 hours, then ultrasonically vibrate at a frequency of 20kHz for 20 minutes.

[0046] The treated slurry was dried in a drying oven for 4 hours, and then calcined at 300° C. for 3 hours in a muffle furnace at different temperatures, and then heated to 500° C. for 6 hours to obtain a catalyst.

[0047] 2. Catalyst performance tes...

Embodiment 3

[0052] 1. Catalyst preparation process

[0053]Weigh 240g of titanium dioxide (grain size 30nm), add 48ml of water, stir and mix at 90°C, after mixing evenly, add 8g of ammonium molybdate, the weight ratio of ammonium molybdate to titanium dioxide is 1:30, continue stirring Uniformly, the slurry after mixing was continued to stir at this temperature for 2 hours.

[0054] In the slurry obtained above, add 4 g of ammonium metavanadate under stirring, the weight ratio of ammonium metavanadate addition to titanium dioxide is 1: 60, then add copper acetate and chromium acetate (mass ratio is about 1: 1) composition Auxiliary 8g, continue to stir evenly for 3 hours, then ultrasonically vibrate at a frequency of 10kHz for 40 minutes.

[0055] The treated slurry was dried in a drying oven for 4 hours, and then calcined in a muffle furnace with temperature zones, first at 350° C. for 3 hours, and then heated to 600° C. for 10 hours to obtain a catalyst.

[0056] 2. Catalyst performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com