Ti-enhanced B4C/SiC multiphase ceramic

A technology of composite phase ceramics and powder, which is applied in the field of Ti-enhanced B4C/SiC composite phase ceramics, which can solve the problems of poor wettability between metal phase and ceramic phase, failure to obtain finished products, and inability to form uniform and stable products, so as to optimize the phase composition , promote the sintering and densification process, and the effect of compact microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

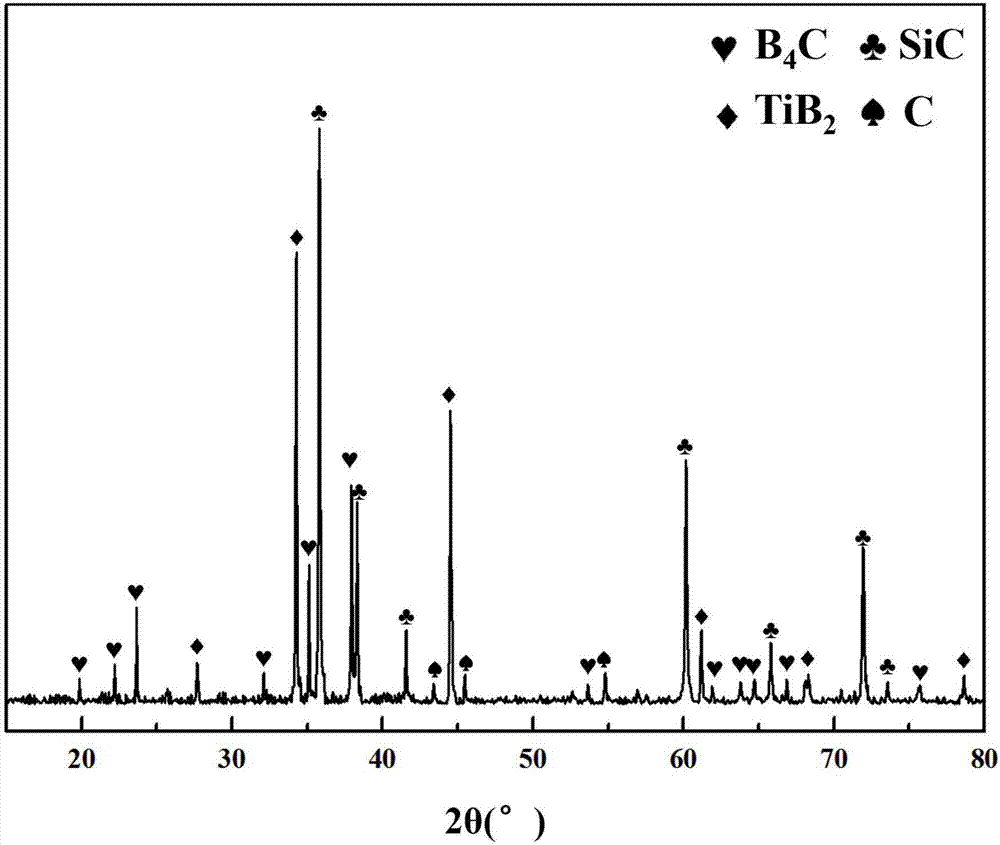

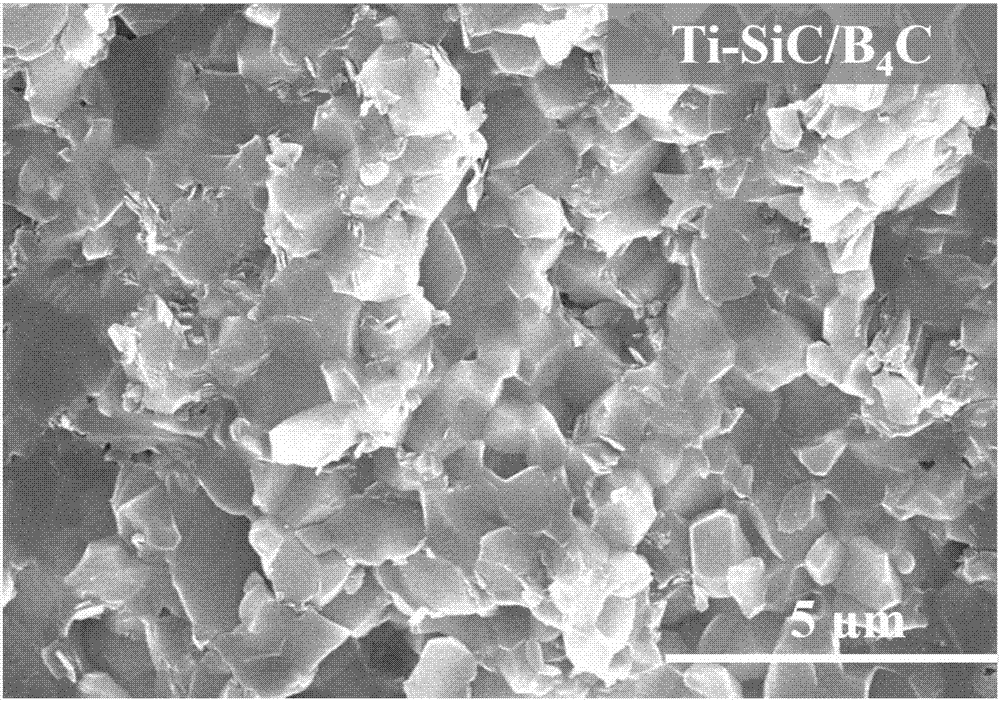

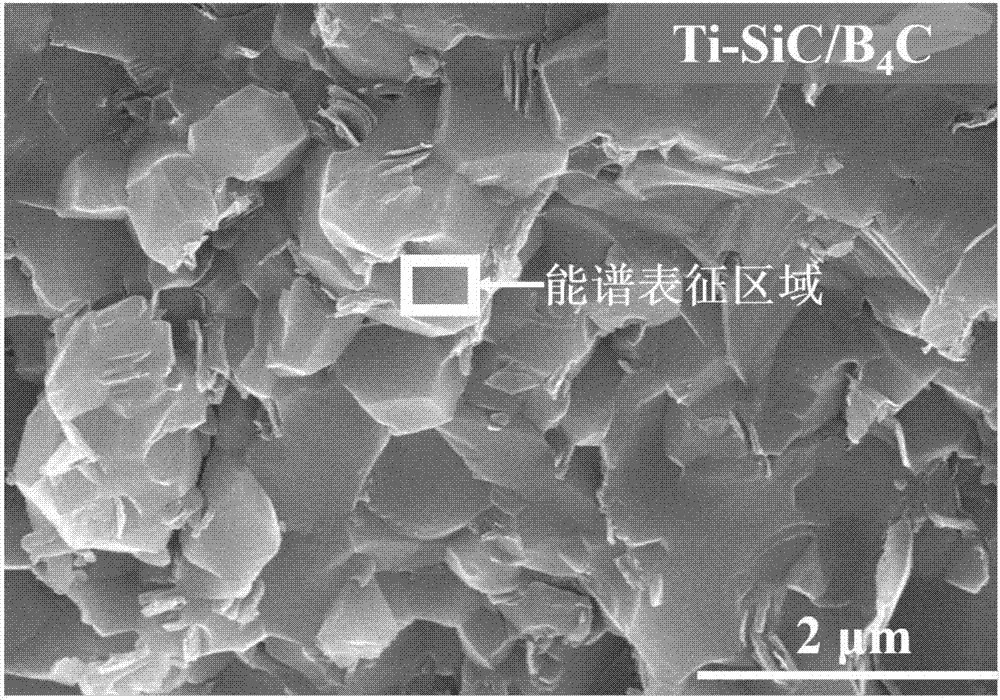

[0034] Step 1. Combine Ti powder, SiC powder, B 4 C powder, PEG4000 and absolute ethanol are mixed according to the mass ratio of 1:1.5:2.5:0.1:20 and moved into the PTFE ball mill tank, and then added into the ball milling medium ZrO according to the ball-to-material ratio of 4:1 2 Balls, and then ball milled at a speed of 150r / min for 48 hours, and then dried the mixed slurry in a vacuum oven at 80°C for 8 hours to obtain a complex powder;

[0035] Step 2. Put the multiphase powder obtained in step 1 in a vacuum hot-pressing sintering furnace until the vacuum degree reaches 6.63×10 - 3 Pa, sintering at a sintering temperature of 1950°C and a sintering pressure of 30MPa for 2 hours, and cooling with the furnace to obtain Ti-enhanced B 4 C / SiC composite ceramics.

[0036] Characterize the composite ceramics prepared in this example: the measured relative density is 98.7%, the microhardness is 40.7GPa, the flexural strength is 576.7MPa, and the fracture toughness is 5.41MPa ...

Embodiment 2

[0040] Step 1. Combine Ti powder, SiC powder, B 4 C powder, PEG4000 and absolute ethanol are mixed according to the mass ratio of 0.5:1.5:2.5:0.1:20 and moved into the PTFE ball milling tank, and then the ball milling medium ZrO is added according to the ball material ratio of 4:1 2 Balls, and then ball milled at a speed of 200r / min for 24 hours, and then dried the mixed slurry in a vacuum oven at 80°C for 8 hours to obtain a complex powder;

[0041] Step 2. Put the multiphase powder obtained in step 1 in a vacuum hot-pressing sintering furnace until the vacuum degree reaches 6.63×10 - 3 Pa, sintering at a sintering temperature of 1950°C and a sintering pressure of 30MPa for 2 hours, and cooling with the furnace to obtain Ti-enhanced B 4 C / SiC composite ceramics.

[0042] Characterize the composite ceramics prepared in this example: the measured relative density is 97.9%, the microhardness is 38.1GPa, the flexural strength is 495.2MPa, and the fracture toughness is 5.13MPa ...

Embodiment 3

[0044] Step 1. Combine Ti powder, SiC powder, B 4 C powder, PEG4000 and absolute ethanol are mixed according to the mass ratio of 1:1.5:2.5:0.1:20 and moved into the PTFE ball mill tank, and then added into the ball milling medium according to the ball-to-material ratio of 4:1 ZrO 2 Balls, and then ball milled at a speed of 150r / min for 48 hours, and then dried the mixed slurry in a vacuum oven at 80°C for 8 hours to obtain a complex powder;

[0045] Step 2. Put the multiphase powder obtained in step 1 in a vacuum hot-pressing sintering furnace until the vacuum degree reaches 6.63×10 - 3 Pa, sintering at a sintering temperature of 1800°C and a sintering pressure of 20MPa for 1h, and cooling with the furnace to obtain Ti-enhanced B 4 C / SiC composite ceramics.

[0046] Characterize the composite ceramics prepared in this example: the measured relative density is 97.4%, the microhardness is 37.5GPa, the flexural strength is 486.2MPa, and the fracture toughness is 4.96MPa m 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com