Method for preparing perovskite layer of perovskite solar cell by using solid-mist interfacial reaction

A solar cell and solid-fog interface technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the problems of poor coverage and poor repeatability of perovskite films, and improve photoelectric conversion efficiency and reaction time Short, easy-to-equip effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

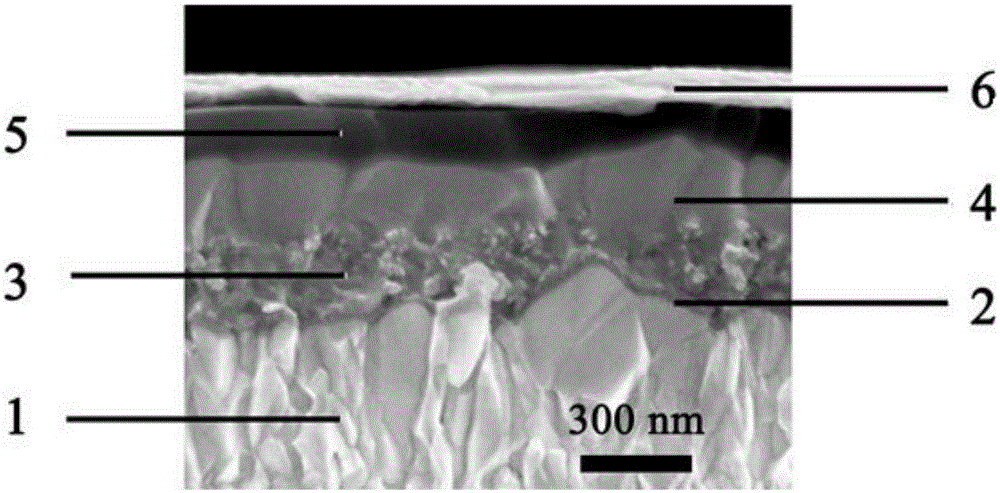

[0024] Based on FTO conductive glass 1; Ti(OPr) 2 (AcAc) 2 It was diluted 10 times with ethanol, and 1.2 mL of the diluted solution was divided into six times on average, and sprayed and pyrolyzed with oxygen as a carrier at a substrate temperature of 450° C. to obtain a dense titanium dioxide film 2 . Mix the purchased titanium dioxide slurry (18NRT, Dyesol) and ethanol uniformly according to the mass ratio of 1:6 to obtain the diluted titanium dioxide slurry, take 50 μL, set the speed of the homogenizer to 5000r / min, and last for 30s. A film of uniform thickness was obtained on the dense titanium dioxide film, and then the prepared film was dried and sintered at a temperature of 80°C, 125°C, 350°C and 500°C, and the duration of each temperature was 30min; remove the film The non-titanium dioxide substances in the obtained porous membrane 3 composed of titanium dioxide nanoparticles.

[0025] Drop 50 μL of dimethylformamide solution of lead iodide with a concentration of 46...

Embodiment 2~7

[0030] The difference between Examples 2-7 and Example 1 is that the preheating, reaction and post-treatment temperatures during the preparation of the perovskite layer are set to 40, 60, 100, 120, 140 and 160°C.

[0031] The average efficiencies obtained based on the solar cells at reaction temperatures of 40, 60, 80, 100, 120, 140, and 160°C were: 10.9%, 14.8%, 15.1%, 15.0%, 14.6%, 11.9%, and 5.7%, respectively, It can be seen that the above-mentioned temperature setting as 80° C. is the optimum temperature.

Embodiment 8 and Embodiment 9

[0033] The difference between Example 8 and Example 9 and Example 1 lies in that the amount of methyl iodide solution used is 50 and 1000 μL, respectively.

[0034] The average efficiencies obtained based on the solar cells prepared with 50 and 1000 μL iodomethylamine solution were: 9.3% and 12.4%, respectively, and the optimal volume of iodomethylamine solution was 400 μL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com