Method for connecting Cf/Al composite with TiAl based on laser ignition and self-propagating reaction

A composite material, laser ignition technology, used in welding/cutting media/materials, laser welding equipment, welding/cutting auxiliary equipment, etc. Good performance, high connection efficiency, guaranteed uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

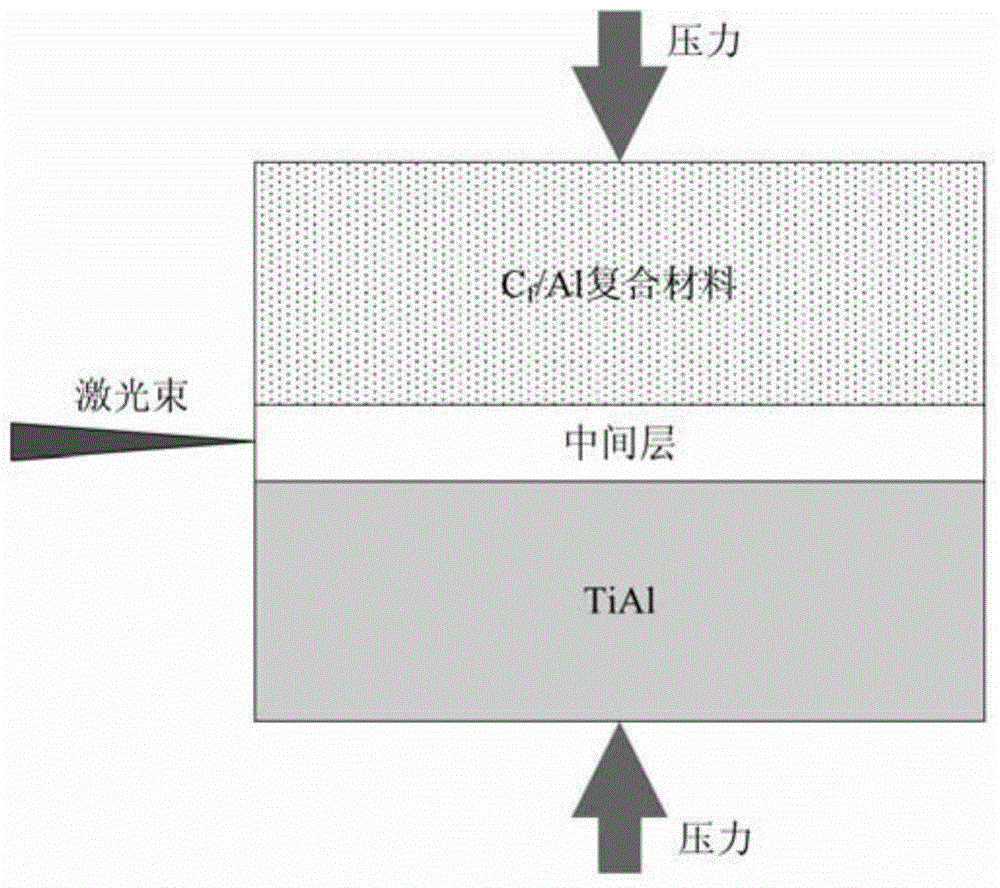

[0013] Specific implementation mode 1: In this implementation mode, the laser ignites the self-propagating connection C f / Al composite material with the method of TiAl, proceed as follows:

[0014] 1. Preparation of mixed powder: Weigh 61-65 parts of nickel powder, 31-33 parts of aluminum powder and 3-7 parts of titanium powder in parts by weight and mix them evenly, then put them in the ball mill tank, and the mass ratio of ball to material is 5 Put the ball into the ball at a ratio of 1, and ball mill at a speed of 300r / min to 500r / min for 2h to 3h under the protection of argon to obtain a mixed powder;

[0015] 2. Preparation of the intermediate layer compact: compress the mixed powder obtained in step 1 into an intermediate layer compact with a relative density of 60% to 80% and a thickness of 1mm to 2mm, and seal it for storage;

[0016] 3. C f / Al composite surface pretreatment and TiAl surface pretreatment: the C f / Al composite surface and TiAl surface with 200 # ...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mesh number of the nickel powder in step 1 is ≥ 200 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mesh number of the aluminum powder described in step 1 is ≥ 325 mesh. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com