Method for preparing particle-enhanced metal matrix composite

A composite material and particle reinforcement technology, which is applied in the field of metal matrix composite material preparation, can solve the problems of reducing interface reaction, uneven distribution, and low production efficiency, and achieve the effects of reducing interface reaction, high cooling rate, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

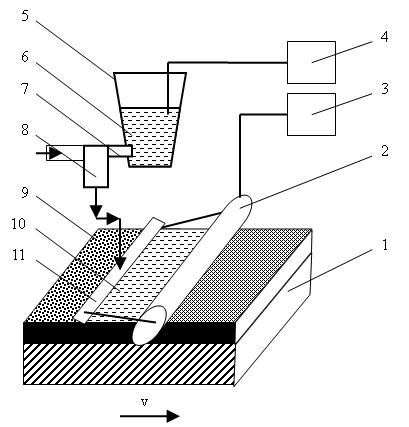

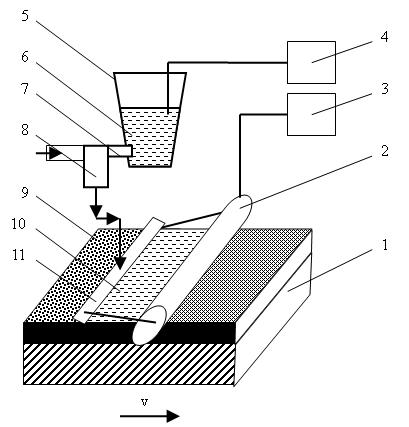

Method used

Image

Examples

Embodiment 1

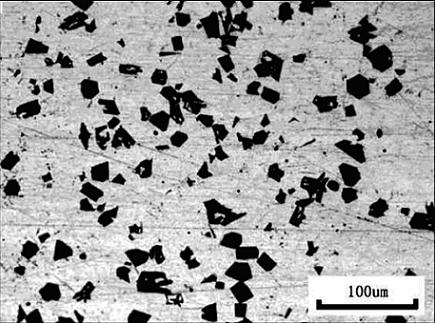

[0021] The selected reinforcement particles are SiC particles with an average size of 25 μm, the theoretical volume fraction of particles is 15%, and the matrix is A356 alloy.

[0022] The equipment is evacuated to 1×10 -3 Pa, the vacuum chamber is filled with argon gas of 20kPa as a protective atmosphere, the aluminum alloy is melted in the crucible according to the composition ratio of A356 aluminum alloy, after purification, the aluminum alloy melt is introduced into the blowing chamber through the diversion hole, and the diversion is closed at the same time Through the inert gas pipe at the upper end of the blowing chamber, inject 50kPa blowing gas from the nozzle to blow the A356 alloy melt at 690°C to the surface of the fast-moving copper substrate (the length of the moving direction is 500mm, and the width is 200mm). The horizontal movement rate is 10000mm / s, the copper substrate is under the nozzle of the blowing device, the vertical distance between the nozzle and t...

Embodiment 2

[0024] The selected reinforcement particles are graphite particles with an average size of 5 μm, the theoretical volume fraction of the particles is 20%, and the matrix is pure copper.

[0025] The equipment is evacuated to 2×10 -3Pa, the vacuum chamber is filled with argon gas of 40kPa as a protective atmosphere, the pure copper is melted in the crucible, and after purification, the pure copper melt is introduced into the blowing chamber through the diversion hole, and at the same time the diversion hole is closed, through the upper end of the blowing chamber The inert gas pipe is fed with 80kPa blowing gas from the nozzle to blow the pure copper melt at 1120°C to the surface of the fast-moving copper substrate (600mm long and 240mm wide in the moving direction), and the horizontal moving speed of the copper substrate is 20000mm / s. The copper substrate is under the nozzle of the blowing device, and the vertical distance from the nozzle is 1.0mm. The thickness of one spray i...

Embodiment 3

[0027] The selected reinforcement particles are TiB with an average size of 50 μm 2 Particles, the theoretical volume fraction of particles is 10%, and the matrix is Mg 65 Cu 25 Y 10 bulk amorphous alloy.

[0028] The equipment is evacuated to 1×10 -3 Pa, the vacuum chamber is filled with 60kPa of argon as a protective atmosphere, according to Mg 65 Cu 25 Y 10 The composition ratio of the bulk amorphous alloy is melted in the crucible, and after purification, the bulk amorphous alloy melt is introduced into the blowing chamber through the diversion hole, and the diversion hole is closed at the same time, and the inert gas pipe at the upper end of the blowing chamber is passed through Inject 120kPa of blowing gas from the nozzle to blow the 620°C bulk amorphous alloy melt onto the surface of the fast-moving copper substrate (the length of the moving direction is 500mm, and the width is 220mm). The horizontal movement rate of the copper substrate is 20000mm / s. The subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com