Method for connecting Cf/Al composite materials and TiAl through laser ignition self-propagating reaction auxiliary brazing

A composite material and laser ignition technology, which is applied in the direction of laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of deterioration of base material performance, interface bond damage, high heating temperature, etc., and achieve high connection efficiency, Good performance, the effect of improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

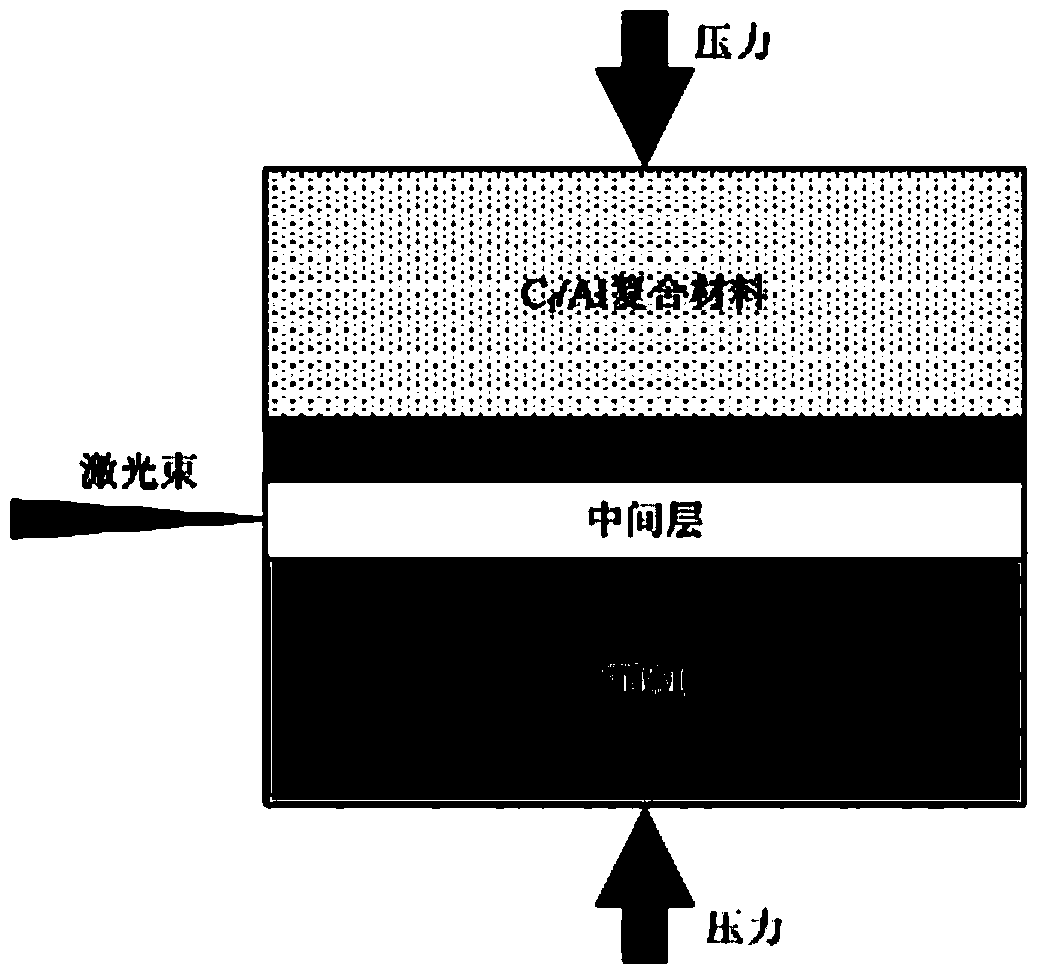

[0014] Specific Embodiment 1: In this embodiment, a laser ignited self-propagating reaction assisted brazing connection C f The method of / Al composite material and TiAl is specifically completed according to the following steps:

[0015] 1. Preparation of nickel powder / aluminum powder mixed powder: take 45 parts to 55 parts of nickel powder and 45 parts to 55 parts of aluminum powder in parts by weight and mix them evenly, then place them in a ball mill tank, and the mass ratio of balls to materials is (5 ~10): 1 ratio into the ball, under the condition of argon protection, ball milling at a speed of 300r / min~500r / min for 2h~3h, to obtain nickel powder / aluminum powder mixed powder;

[0016] 2. Preparation of the intermediate layer compact: the nickel powder / aluminum powder mixed powder obtained in step 1 is pressed into an intermediate laminate compact with a relative density of 60% to 80% and a thickness of 1 mm to 2 mm, and sealed for storage;

[0017] 3. Surface pretreatm...

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 in that: the mesh number of the nickel powder in step 1 is ≥ 200 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mesh number of the aluminum powder described in step 1 is ≥ 325 mesh. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com