Circular diamond saw blade bit and manufacturing method thereof

A technology of circular saw blades and diamonds, which is applied in the field of diamond circular saw blades and its preparation, can solve the problems of difficult control of the shape retention of the cutter head, difficulty in uniform size shrinkage, low hardness and low density, and avoid graphite Die loss, easy industrialization promotion, and the effect of improving sinterability and deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of cutter head of the present invention adopts free sintering method, specifically as follows:

[0037] Mixing step: mix the above-mentioned carcass powder (preferably the above-mentioned pre-alloyed carcass powder) and diamond particles for 0.5-1 hour to make them uniform, and then add an appropriate amount of granulating agent to continue mixing for 0.5-1 hour to make them uniform, wherein the diamond particles The mass ratio of the mass of the matrix powder to the total mass of the diamond particles is 1.5-4%, and the ratio of the mass of the granulating agent to the total mass of the matrix powder and the diamond particles is 0.1:99.9~0.3:99.7. The total time is 1-2 hours; the granulating agent can be a commonly used granulating agent in this field, such as liquid paraffin.

[0038] Cold pressing forming step: according to the preset amount of powder, put the mixed material obtained in the mixing step into the cavity of the assembled pressing mo...

Embodiment 1

[0044] In this example, the composition of the carcass powder F-01 is shown in Table 1. The carcass powder F-01 is a pre-alloyed carcass powder prepared by the water atomization method commonly used in this field. The components in the carcass powder The purity of each is more than 99.5%, and its basic properties are shown in Table 2.

[0045] Table 1F-01 Composition and content of powder, wt%

[0046] Powder code

Cu

Ni

sn

co

Ti

Cr

P

Al

Fe

F-01

20

2

2

3

1

1

2

1

Remain

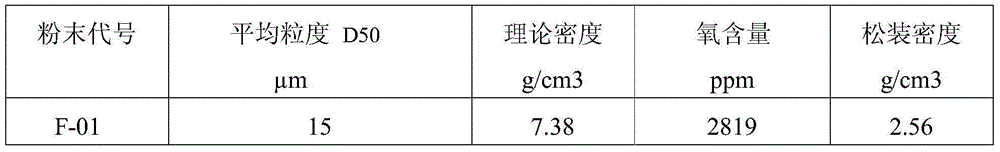

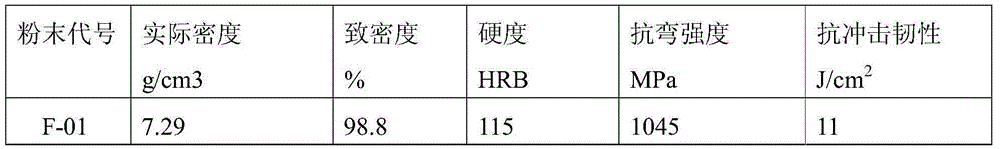

[0047] Table 2F-01 Basic properties of powder

[0048]

[0049] The median diameter D50 of the added diamond particles is 40 μm, accounting for 2% of the mass percentage of the diamond cutter head.

[0050] The preparation method of the diamond circular saw blade cutter head in the present embodiment is as follows:

[0051] Mixing step: mix the above matrix powder and diamond particles for 1 hour to make them u...

Embodiment 2

[0059] In this example, the composition of the carcass powder F-02 is shown in Table 4. The carcass powder F-02 is a pre-alloyed carcass powder prepared by the water atomization method commonly used in this field. The components in the carcass powder The purity of each is more than 99.5%, and its basic properties are shown in Table 5.

[0060] Table 4F-02 Composition and content of powder, wt%

[0061] Powder code

Cu

Ni

sn

co

mn

Si

Fe

[0062] F-02

30

8

3

5

2

1

Remain

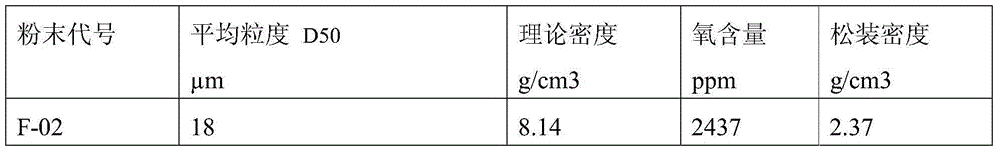

[0063] Table 5F-02 Basic properties of powder

[0064]

[0065] The median diameter D50 of the added diamond particles is 35 μm, accounting for 1.5% of the mass percentage of the diamond cutter head.

[0066] The preparation method of the diamond circular saw blade cutter head in the present embodiment is as follows:

[0067] Mixing step: mix the above matrix powder and diamond particles for 45 minutes to make them u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com