Articles having a surface with low wettability and method of making

a technology of liquid wettability and surface, applied in the direction of roads, instruments, traffic signals, etc., can solve the problems high degree of “sheeting” of water over the solid surface, and inability to thermally or chemically stable, etc., to achieve the effect of low liquid wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description, like reference characters designate like or corresponding parts throughout the several views shown in the figures. It is also understood that terms such as “top,”“bottom,”“outward,”“inward,” and the like are words of convenience and are not to be construed as limiting terms. Furthermore, whenever a particular feature of the invention is said to comprise or consist of at least one of a number of elements of a group and combinations thereof, it is understood that the feature may comprise or consist of any of the elements of the group, either individually or in combination with any of the other elements of that group.

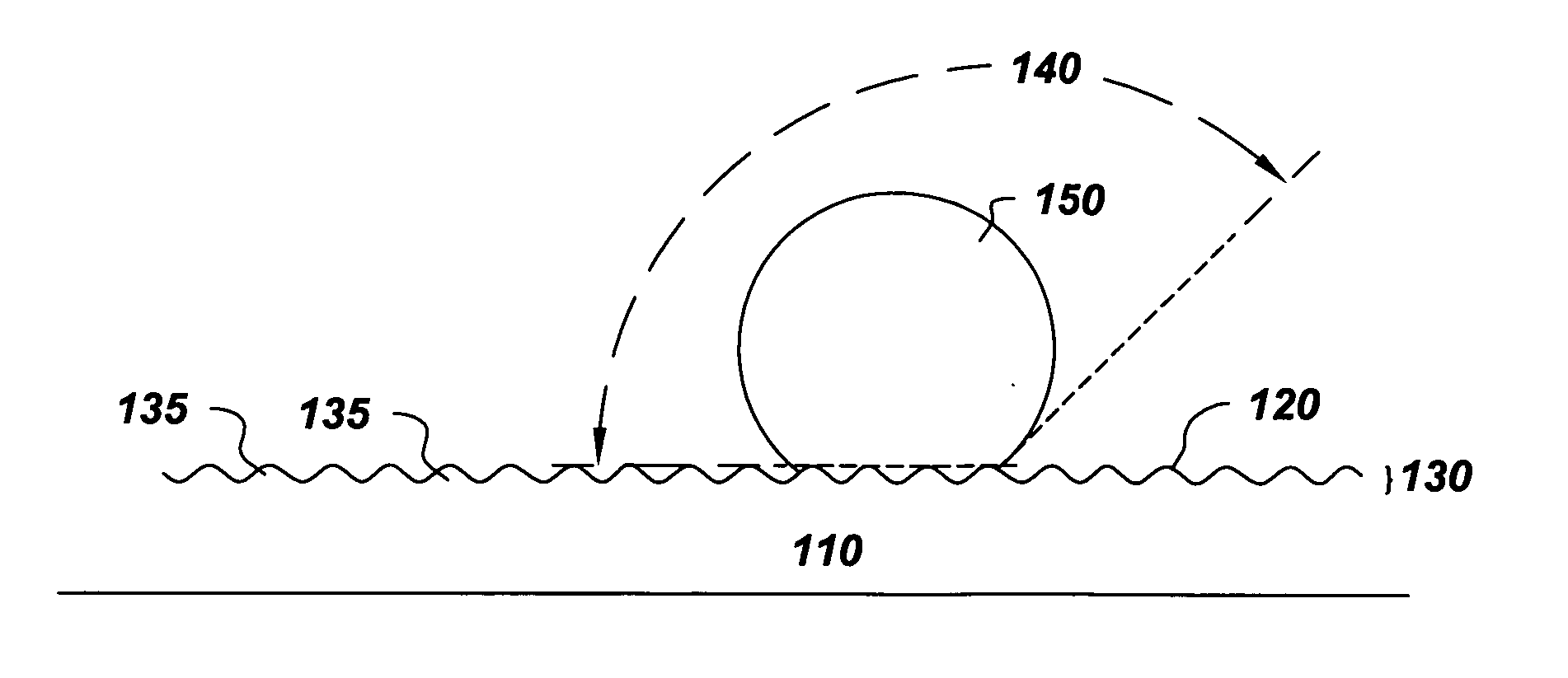

[0030] Referring to the drawings in general and to FIG. 1 in particular, it will be understood that the illustrations are for the purpose of describing a particular embodiment of the invention and are not intended to limit the invention thereto. FIG. 1 is a schematic cross-sectional view of a surface of an article of the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com