Noise reduction type air outlet hood for extractor hood

A range hood and noise reduction technology, which is applied in the field of noise reduction wind hood, can solve problems such as poor noise reduction effect, and achieve the effect of good noise reduction and noise reduction and the best noise reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

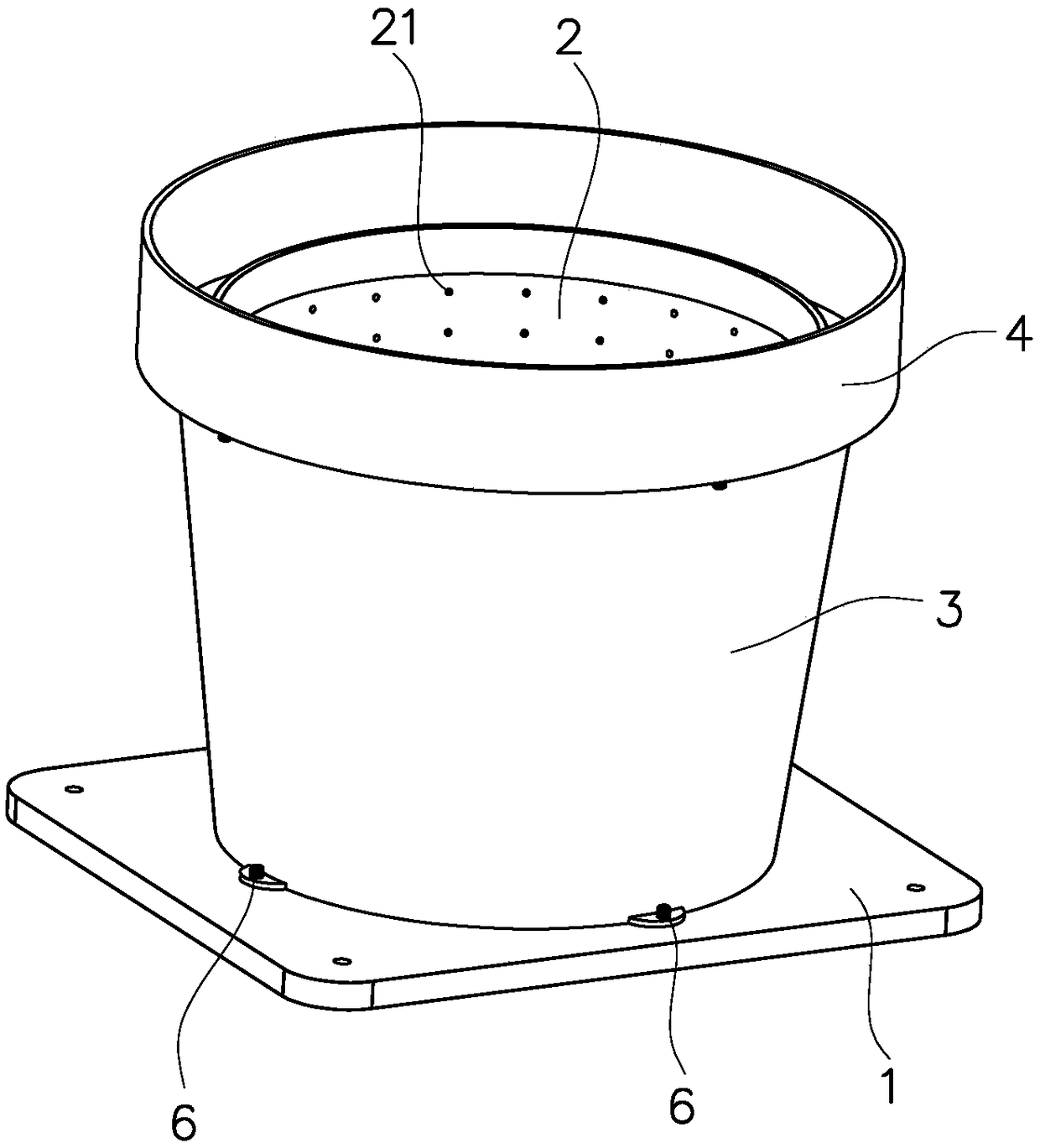

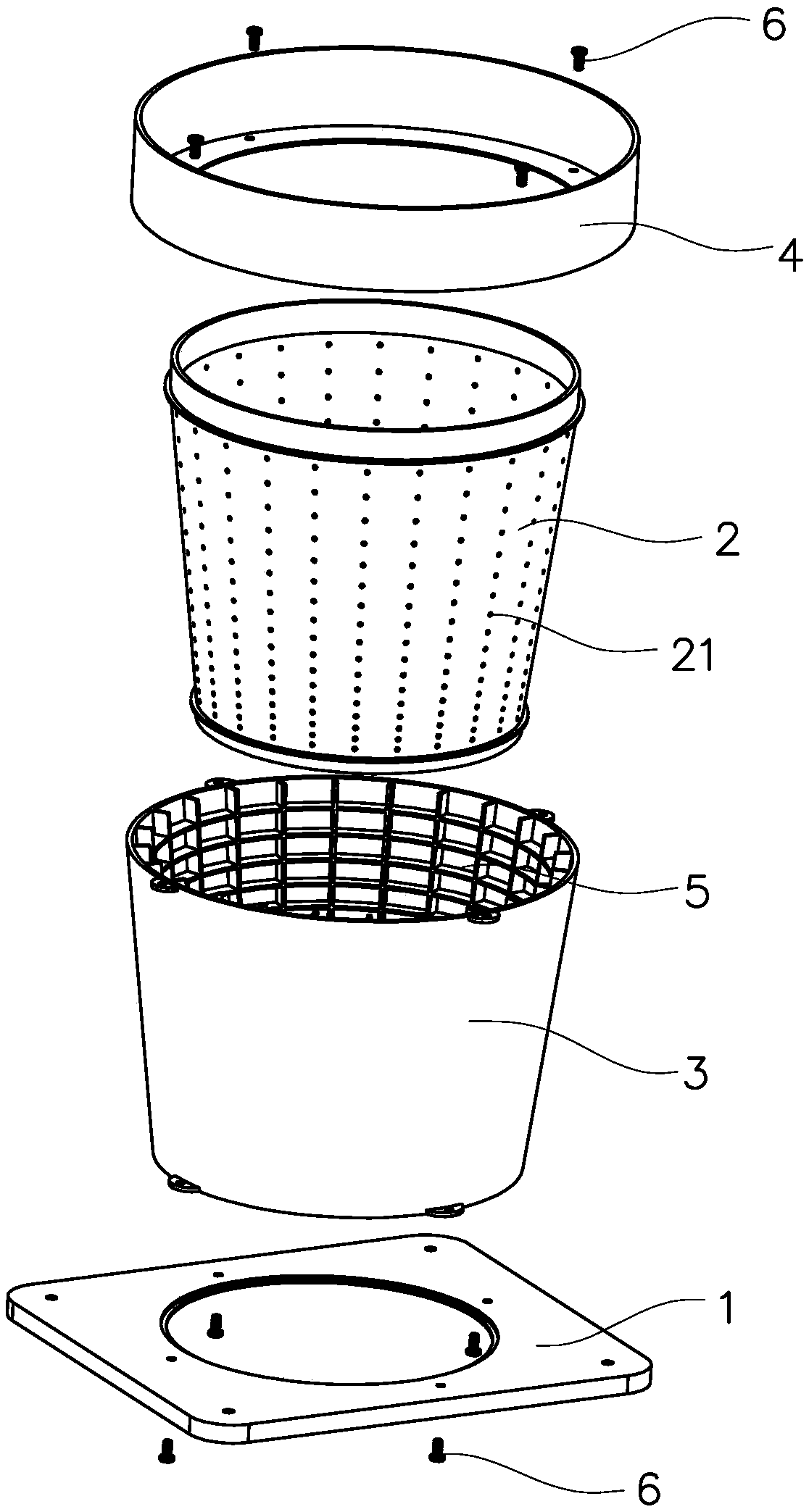

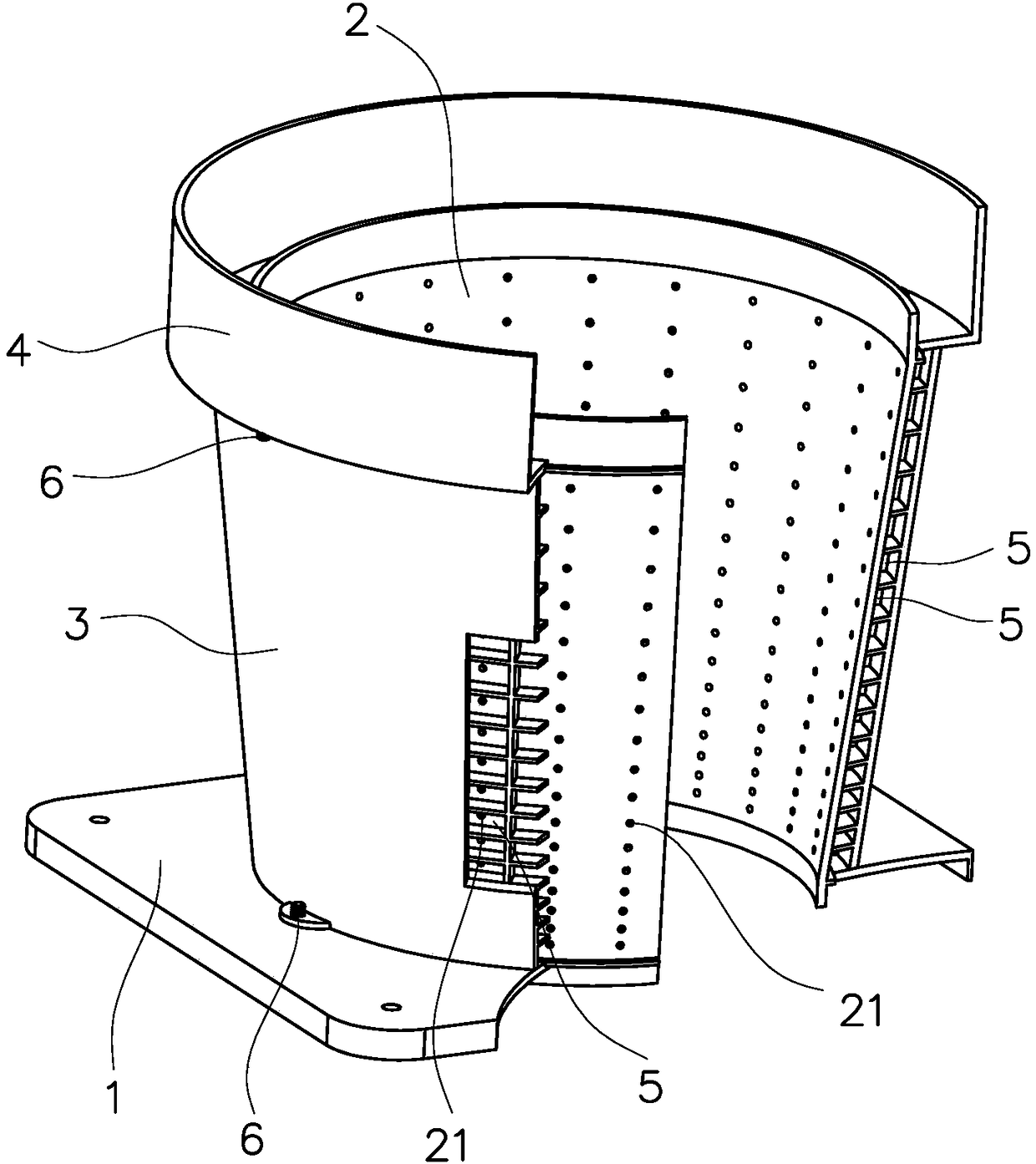

[0027] Such as Figure 1 to Figure 5 As shown, the noise-reducing air outlet hood of the range hood in this embodiment includes main components such as a base 1 , an inner cover 2 , an outer cover 3 , and an air outlet ring 4 . An upper sealing ring 41 is formed on the bottom of the air outlet ring 4, and a lower sealing ring 11 is formed on the base 1. The top of the inner cover 2 is sealed and connected to the upper sealing ring 41, and the bottom of the inner cover 2 is sealed and connected to the lower sealing ring 11. Above, the top of the cover 3 is fastened to the air outlet ring 4 by screws 6 , and the bottom of the cover 3 is fastened to the base 1 by screws 6 .

[0028] In this embodiment, a plurality of noise reduction holes 21 are opened on the peripheral wall of the inner cover 2, and the noise reduction holes 21 are round holes. A plurality of noise reduction holes 21 corresponding to the noise reduction holes 21 are formed between the inner cover 2 and the outer...

Embodiment 2

[0033] Such as Figure 6 As shown, the noise reduction cavity 5 of the air outlet hood of this embodiment is formed on the outer wall of the inner cover 2. Similarly, a noise reduction cavity 5 corresponds to a noise reduction hole 21. The noise reduction principle is the same as that of the first embodiment. This does not expand the description.

Embodiment 3

[0035] The noise reduction chamber 5 in this embodiment is a ring noise reduction chamber distributed along the horizontal plane, and the noise reduction holes 21 on the same horizontal ring surface are all arranged in the same ring noise reduction chamber.

[0036] Such as Figure 7 As shown, the ring noise reduction cavity is located on the inner wall of the outer cover 3, as Figure 8 As shown, the ring-shaped noise reduction cavity is arranged on the outer wall of the inner cover 2 . Figure 7 and Figure 8 In the two structures shown, multiple noise reduction holes 21 correspond to one noise reduction cavity 5 to form a parallel resonant cavity. The principle of noise reduction is the same as that of Embodiment 1, and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com